This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

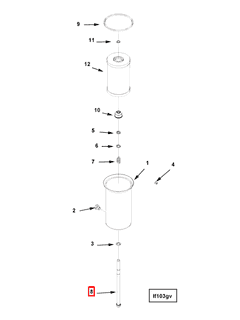

The Shell Retaining Bolt (Part #173177) by Cummins is a specialized component designed for use in heavy-duty truck engines. Its purpose is to secure shell bearings within the engine, ensuring they remain in place under operational conditions. This bolt plays a significant role in maintaining the integrity and performance of the engine by facilitating the proper functioning of the bearing system 1.

Basic Concepts of Shell Retaining Bolts

Shell retaining bolts are fasteners used in internal combustion engines to hold shell bearings in position. These bearings support the crankshaft and other rotating parts, reducing friction and wear. The shell retaining bolt operates by threading into a designated location within the engine block or bearing cap, applying pressure to keep the bearing shell firmly in place 2.

Purpose of the 173177 Shell Retaining Bolt

The 173177 Shell Retaining Bolt is specifically engineered to secure shell bearings in Cummins heavy-duty truck engines. By holding the bearings in the correct position, this bolt ensures that the crankshaft operates smoothly and efficiently. This is achieved by maintaining the precise alignment and clearance necessary for optimal engine performance 3.

Key Features

The 173177 Shell Retaining Bolt is constructed from high-strength materials, ensuring durability and reliability under the demanding conditions of heavy-duty truck engines. Its design includes specific threading and head configurations that provide a secure fit and easy installation. Additionally, the bolt may feature coatings or treatments that enhance its resistance to corrosion and wear, contributing to its longevity and performance.

Benefits

Utilizing the 173177 Shell Retaining Bolt offers several advantages. It contributes to improved engine reliability by ensuring that shell bearings remain securely in place. This results in enhanced engine performance and longevity of engine components, as the proper functioning of bearings is vital for the overall health of the engine. The bolt’s robust construction and design also help in reducing maintenance needs and extending the service life of the engine.

Installation Process

Installing the 173177 Shell Retaining Bolt requires careful attention to detail to ensure proper function and durability. The process involves threading the bolt into the engine block or bearing cap, ensuring it is tightened to the manufacturer’s specified torque settings. It is important to use the correct tools and follow best practices to avoid over-tightening or cross-threading, which could lead to damage or failure.

Troubleshooting and Maintenance

Common issues with shell retaining bolts may include loosening over time, corrosion, or damage from improper installation. Regular inspection and maintenance can help identify these problems early. Diagnostic procedures may involve checking for proper torque, signs of wear or corrosion, and ensuring that the bearing shells are correctly positioned. Maintenance tips include using appropriate lubricants, ensuring a clean installation environment, and following recommended service intervals for inspection and replacement.

Compatibility and Application

The 173177 Shell Retaining Bolt is designed for use with specific Cummins engine models, ensuring compatibility and optimal performance. Its application extends to various types of heavy-duty trucks, where reliable engine operation is paramount. Understanding the compatibility of this bolt with different engine models is crucial for ensuring proper fit and function.

Manufacturer - Cummins

Cummins Inc. is a leading manufacturer in the automotive industry, known for its high-quality engine components. With a rich history and a strong reputation for reliability and performance, Cummins is committed to producing components that meet the demanding requirements of heavy-duty applications. The 173177 Shell Retaining Bolt is a testament to Cummins’ dedication to quality and innovation in engine component manufacturing.

Role of Part 173177 Shell Retaining Bolt in Engine Systems

In the context of engine systems, the Part 173177 Shell Retaining Bolt is instrumental in ensuring the secure assembly and operation of various components. This bolt is specifically designed to retain shells within the system, thereby maintaining the integrity and efficiency of the engine’s filtration and lubrication processes.

Integration with Filtration Systems

-

Full Flow Oil Filter: The Shell Retaining Bolt plays a significant role in securing the full flow oil filter. By ensuring that the filter shell remains firmly in place, it helps maintain consistent oil flow and filtration efficiency, which is essential for engine protection.

-

Lubricating Oil Filter: In lubricating oil filter systems, this bolt ensures that the filter shell is correctly positioned. This is vital for the effective removal of contaminants from the lubricating oil, thereby prolonging the life of engine components.

-

Lubricating Oil Duplex Filter: For systems employing a lubricating oil duplex filter, the Shell Retaining Bolt is used to secure both filter shells. This dual filtration setup enhances the engine’s reliability by providing a backup filtration path in case one filter becomes clogged.

Application in Gear Boxes

In gear box applications, the Shell Retaining Bolt is essential for securing the filter shells within the lubrication system. This ensures that the gear box oil is adequately filtered, reducing wear on gears and other moving parts, and enhancing the overall performance and longevity of the gear box.

Oil Filter and Gages

When integrated with oil filter and gage systems, the Shell Retaining Bolt ensures that the filter shell is held securely in place. This is important for accurate oil pressure readings and efficient oil filtration, both of which are critical for maintaining engine health.

Oil Filter / Cooler Systems

In systems where an oil filter is combined with an oil cooler, the Shell Retaining Bolt ensures that the filter shell is properly secured. This is important for maintaining the efficiency of both the filtration and cooling processes, which are essential for optimal engine operation.

Conclusion

By understanding the role of the Part 173177 Shell Retaining Bolt in these various engine systems, engineers and mechanics can better appreciate its importance in maintaining the overall performance and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.