This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 198940 Tube Retainer, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems aimed at enhancing the performance and reliability of commercial vehicles. This Cummins part contributes to the efficient operation of trucks by ensuring the secure placement of tubes within the engine system.

Purpose and Function

This part plays a role in the operation of a truck by securing tubes in place within the engine system. Its placement is important to maintaining the structural integrity and alignment of the tubes, which are vital for the flow of fluids or gases necessary for engine operation. By holding the tubes in the correct position, the retainer helps to ensure that the system functions smoothly, reducing the risk of leaks or misalignment that could affect performance 1.

Key Features

The 198940 is characterized by several key features that enhance its functionality. It is constructed from durable materials that can withstand the high temperatures and pressures present in a truck’s engine compartment. The design of the retainer includes precise fittings that allow for a secure connection to the tubes, ensuring that they remain in place under various operating conditions. Additionally, the retainer may feature corrosion-resistant coatings or treatments to prolong its lifespan in harsh environments 2.

Benefits

The advantages of using the 198940 include improved system efficiency and durability. By securely holding the tubes in place, the retainer helps to maintain the integrity of the engine’s fluid or gas pathways, which can lead to more consistent performance. The durable construction of the retainer also contributes to its longevity, potentially reducing the need for frequent replacements and associated costs for fleet operators 3.

Installation Process

Proper installation of the 198940 involves several steps to ensure it functions correctly. Begin by identifying the correct location for the retainer within the engine system. Carefully align the retainer with the tubes, ensuring that all connections are secure and tight. It is important to follow manufacturer guidelines to avoid over-tightening, which could damage the tubes or the retainer itself. After installation, perform a system check to confirm that the retainer is functioning as intended and that there are no leaks or misalignments.

Maintenance Tips

To ensure the longevity and optimal performance of the 198940, regular maintenance is recommended. Inspect the retainer during routine engine checks for signs of wear, corrosion, or damage. Cleaning the retainer and its connections can help prevent buildup that might affect its function. If any issues are detected, address them promptly to avoid more significant problems down the line.

Troubleshooting Common Issues

Frequent problems associated with the 198940 may include leaks due to improper installation or wear over time. To address these issues, first, ensure that the retainer is correctly installed and all connections are secure. If wear is detected, evaluate whether the retainer needs to be replaced or if minor repairs can suffice. Regular maintenance can help identify and resolve these issues before they lead to more substantial engine problems.

Manufacturer Overview - Cummins

Cummins is a renowned manufacturer in the commercial truck industry, known for its wide range of engine and component products. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance parts. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

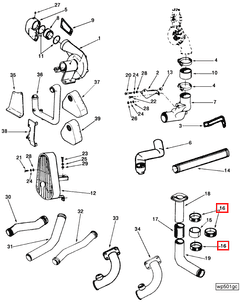

Cummins Part 198940 Tube Retainer in V28 Engines

The Tube Retainer part 198940 by Cummins is a component in the V28 engine series. This part plays a role in maintaining the integrity and functionality of the engine’s cooling system. It is designed to secure coolant tubes in place, ensuring that they remain properly aligned and sealed throughout the engine’s operation.

In the V28 engine, the Tube Retainer part 198940 is integral to the engine’s overall cooling mechanism. It helps prevent leaks and ensures that the coolant flows efficiently, which is important for maintaining optimal engine temperature and performance. The design of this part ensures that it can withstand the high pressures and temperatures typically encountered in engine environments.

The Tube Retainer part 198940 is engineered to fit seamlessly with the V28 engine’s architecture, providing a reliable connection point for the coolant tubes. Its placement is important, as it directly impacts the engine’s cooling efficiency and longevity. The material used in the construction of this part is chosen for its durability and resistance to corrosion, ensuring that it can perform reliably over extended periods.

In the V28 engine series, the Tube Retainer part 198940 is a standardized component, meaning it is designed to fit all variants within this engine group. This standardization ensures that maintenance and repair processes are streamlined, as the same part can be used across multiple engine models. This not only simplifies inventory management for service providers but also ensures consistency in performance and reliability.

Role of Part 198940 Tube Retainer in Engine Systems

The 198940 Tube Retainer is a component in maintaining the integrity and efficiency of various engine systems. Its primary function is to secure and stabilize tubes within these systems, ensuring optimal performance and longevity.

Integration with Filter Cooler and Oil Filter/Cooler Systems

In filter cooler and oil filter/cooler systems, the 198940 Tube Retainer plays a role by holding the tubes in place. This ensures that the flow of fluid through the system remains consistent and unimpeded. By securing the tubes, the retainer prevents vibrations and movements that could lead to leaks or reduced efficiency in the cooling process. This stability is particularly important in high-stress environments where engine components are subject to constant motion and thermal expansion.

Application in Transfer Mounting Tube Systems

When integrated with transfer mounting tube systems, the 198940 Tube Retainer ensures that the mounting tubes remain firmly in position. This is vital for the structural integrity of the system, as it prevents the tubes from shifting or detaching under operational stress. The retainer’s role here is to provide a secure attachment point, which is important for the reliable transfer of fluids or gases within the engine system. This security is paramount in maintaining the system’s overall performance and preventing potential failures.

Function in Water Transfer Tube Systems

In water transfer tube systems, the 198940 Tube Retainer is instrumental in maintaining the precise alignment and connection of water transfer tubes. This is crucial for the efficient circulation of water within the engine, which is often used for cooling purposes. By ensuring that the tubes are held securely in place, the retainer helps to maintain a consistent water flow, which is essential for effective engine cooling. This, in turn, contributes to the engine’s overall efficiency and reliability.

Overall, the 198940 Tube Retainer is a key component in various engine systems, providing the necessary support and stability to ensure that tubes remain in their intended positions. This contributes to the efficient and reliable operation of the engine, highlighting the importance of this often-overlooked part in maintaining engine performance.

Conclusion

The 198940 Tube Retainer by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its role in securing and stabilizing tubes within various engine systems ensures optimal performance, efficiency, and longevity. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential to maximizing the benefits of this part. As a standardized component in the V28 engine series, the 198940 Tube Retainer simplifies maintenance and repair processes, ensuring consistency in performance and reliability across multiple engine models.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.