This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 253957 Retaining Ring is a specialized component designed for use in commercial trucks. Its primary function is to secure various parts within the truck’s mechanical systems, ensuring they remain in place under operational conditions. This retaining ring is integral to maintaining the integrity and efficiency of the truck’s components, contributing to overall performance and reliability.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They function by creating a secure fit that holds parts in place, preventing axial movement. Retaining rings are commonly used in various mechanical systems to ensure that components remain correctly positioned, which is vital for the proper functioning of machinery 1.

Purpose of the Cummins 253957 Retaining Ring

The Cummins 253957 Retaining Ring plays a specific role in the operation of commercial trucks by securing components within the engine and transmission systems. It is typically used to hold gears, bearings, and other parts in place, ensuring they do not shift during operation. This stability is crucial for the efficient transfer of power and the smooth operation of the truck’s mechanical systems 2.

Key Features

The Cummins 253957 Retaining Ring is crafted from high-quality materials, ensuring durability and reliability. Its design specifications include a precise fit that allows for easy installation and removal while providing a secure hold. The ring’s unique attributes, such as its corrosion-resistant properties and robust construction, enhance its functionality in demanding commercial truck environments 3.

Benefits

Using the Cummins 253957 Retaining Ring offers several advantages. Its durable construction ensures long-lasting performance, reducing the need for frequent replacements. The ring’s design allows for straightforward installation, minimizing downtime during maintenance procedures. Additionally, the secure fit provided by the retaining ring enhances the overall performance and reliability of the truck’s mechanical systems.

Installation Process

Installing the Cummins 253957 Retaining Ring requires careful attention to detail to ensure a secure fit. The process involves using appropriate tools, such as retaining ring pliers, to place the ring in the designated groove. It is important to follow best practices, including ensuring the groove is clean and free of debris, to achieve a proper fit. Proper installation is vital for the ring to function effectively and maintain the integrity of the mechanical system.

Common Issues and Troubleshooting

Typical problems associated with retaining rings include displacement or wear over time. These issues can lead to component misalignment and potential system failure. Troubleshooting methods involve regular inspections to identify signs of wear or displacement. If issues are detected, the retaining ring should be replaced to restore the secure fit and ensure the continued reliable operation of the truck’s mechanical systems.

Maintenance Tips

Regular maintenance of the Cummins 253957 Retaining Ring is essential for ensuring its longevity and reliable performance. This includes periodic inspections to check for signs of wear, corrosion, or displacement. Replacement guidelines should be followed to address any detected issues promptly. Adhering to these maintenance practices helps maintain the integrity of the truck’s mechanical systems and ensures optimal performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial trucking applications.

Cummins Part 253957: Retaining Ring Compatibility

The Cummins part 253957, a Retaining Ring, is designed to fit seamlessly within the operational framework of specific engine models. This retaining ring plays a crucial role in ensuring the stability and functionality of the engine components it is paired with.

L10 GAS and L10 MECHANICAL Engines

For the L10 GAS and L10 MECHANICAL engines, the retaining ring is an essential component that helps maintain the integrity of the engine’s internal mechanisms. It is strategically placed to secure various parts, preventing unwanted movement and ensuring that the engine operates smoothly. The precision engineering of this retaining ring is vital for the overall performance and longevity of these engines.

The retaining ring’s design allows it to fit snugly within the specified engine models, providing a reliable barrier that keeps components in their designated positions. This is particularly important in high-stress environments where the engine is subjected to significant forces and vibrations. The compatibility of the retaining ring with both the L10 GAS and L10 MECHANICAL engines underscores its versatility and importance in maintaining engine efficiency and reliability.

Role of Part 253957 Retaining Ring in Engine Systems

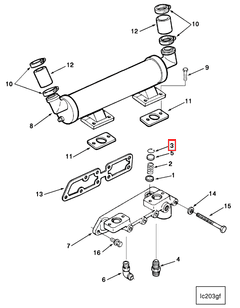

The Part 253957 Retaining Ring is instrumental in ensuring the secure and efficient operation of various engine components. In the Cooler system, this retaining ring plays a significant role in maintaining the integrity of the connections, ensuring that the cooler operates within optimal parameters by preventing leaks and maintaining pressure.

Within the Engine Oil system, the retaining ring is employed in the Lubricating Oil Assembly Top Level Assembly Support. Here, it secures components in place, allowing for smooth operation and reducing the risk of part misalignment or failure.

In the Lubricating Oil Cooler, the retaining ring is vital for securing the connections between the cooler and the surrounding system. This ensures efficient heat exchange and maintains the oil at the correct temperature for engine performance.

The Lubricating Oil Filter Head also benefits from the retaining ring. By securing the filter head components, it ensures that the filtration process is effective, removing contaminants from the oil and prolonging engine life.

In the Lubricating Oil Filter Top Level Assembly Head, the retaining ring helps in maintaining the structural integrity of the assembly. This is essential for consistent filtration performance and preventing oil contamination.

Similarly, in the Lubricating Oil Top Level Assembly Support, the retaining ring ensures that all components are held firmly in place. This is important for the overall stability and efficiency of the lubricating oil system.

The Oil Cooler Support system also utilizes the retaining ring to secure the cooler in place. This is important for maintaining the cooler’s position and ensuring it functions correctly within the engine system.

Lastly, in the Turbocharger Oil Feed Kit, the retaining ring is used to secure the oil feed lines and connections. This ensures that the turbocharger receives a consistent supply of oil, which is essential for its operation and longevity.

Overall, the Part 253957 Retaining Ring is a key component in various engine systems, providing the necessary security and stability for optimal performance.

Conclusion

The Cummins 253957 Retaining Ring is a critical component in the maintenance and operation of commercial truck engines. Its role in securing various engine components ensures the stability and efficiency of the mechanical systems. Proper installation, regular maintenance, and timely replacement are essential practices to maintain the integrity and performance of the truck’s engine systems.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.