This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

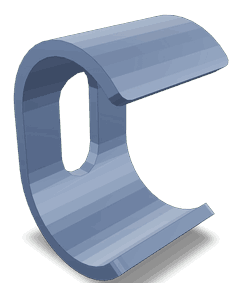

The 2830267 Retaining Clamp, manufactured by Cummins, plays a significant role in the commercial truck industry, contributing to the efficiency and safety of truck systems 1.

Purpose of the 2830267 Retaining Clamp

This Cummins part is designed to secure various components within a truck’s system, ensuring they remain in place under operational conditions. This function is crucial for maintaining the stability and safety of the truck, preventing components from shifting or becoming dislodged during use 2.

Basic Concepts Related to Retaining Clamps

Retaining clamps are mechanical devices used to hold components in place, integral to the integrity and performance of various mechanical systems, including those found in trucks. By securing components, retaining clamps help maintain the alignment and functionality of these systems, contributing to the overall reliability of the truck 3.

Key Features of the 2830267 Retaining Clamp

The 2830267 is characterized by its robust design and construction, made from high-quality materials that ensure durability and long-term performance. It features a design that allows for easy installation and adjustment, enhancing its usability in various truck systems. Additionally, its construction includes elements that provide enhanced grip and stability, further contributing to its effectiveness in securing components 4.

Benefits of Using the 2830267 Retaining Clamp

Utilizing this part offers several advantages. It provides improved security for components, reducing the risk of them becoming dislodged during operation. This increased security leads to reduced maintenance needs, as components are less likely to require adjustment or replacement. Furthermore, the clamp contributes to enhanced operational reliability, ensuring that the truck operates smoothly and safely.

Installation and Usage Guidelines

Proper installation of the 2830267 involves several steps. First, identify the components that require securing. Then, position the clamp around these components, ensuring it is aligned correctly. Tighten the clamp to the manufacturer’s specifications, taking care not to overtighten, which could damage the components or the clamp itself. Regular checks should be performed to ensure the clamp remains secure and functional.

Troubleshooting Common Issues

Common issues with retaining clamps may include loosening over time or difficulty in securing components properly. These problems can often be traced back to incorrect installation, wear and tear, or environmental factors. Solutions may involve re-tightening the clamp, inspecting for damage, or replacing the clamp if necessary. Regular maintenance and inspections can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance of the 2830267 is crucial for its longevity and effectiveness. This includes routine inspections to check for signs of wear or damage, cleaning the clamp to remove any debris that may affect its grip, and ensuring it remains properly tightened. If the clamp shows significant wear or if it fails to secure components effectively, it may be time to consider replacement.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its wide range of high-quality products. With a history of innovation and excellence, Cummins has established a strong reputation for producing reliable and efficient components. Their product range includes engines, filtration systems, and various other parts that contribute to the performance and safety of commercial trucks.

Retaining Clamp Part 2830267 Compatibility with Cummins Engines

The Retaining Clamp part number 2830267, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the engine’s assembly, ensuring that components remain securely fastened and in place. Below is a detailed look at the compatibility of this retaining clamp with specific Cummins engine models.

ISB/ISD6.7 CM2150 SN

The ISB/ISD6.7 CM2150 SN engines benefit from the use of the 2830267 retaining clamp. This part is crucial in maintaining the integrity of the engine’s components, ensuring that they are properly aligned and secured during operation.

ISBE CM800

In the ISBE CM800 engine, the 2830267 retaining clamp is used to secure various parts, contributing to the overall stability and performance of the engine. Its role is vital in preventing any unwanted movement that could lead to mechanical issues.

ISBE4 CM850

The ISBE4 CM850 engine also utilizes the 2830267 retaining clamp. This part is essential in maintaining the alignment and securing the components within this engine model, ensuring smooth and efficient operation.

QSB4.5 CM850 (CM2850)

For the QSB4.5 CM850 (CM2850) engine, the 2830267 retaining clamp is a key component in the engine’s assembly. It ensures that all parts are held firmly in place, contributing to the engine’s reliability and performance.

By understanding the compatibility of the 2830267 retaining clamp with these Cummins engine models, technicians and engine owners can ensure that their engines are properly maintained and functioning optimally.

Role of Part 2830267 Retaining Clamp in Engine Systems

The Retaining Clamp, identified as part 2830267, is instrumental in ensuring the secure and efficient operation of various engine components. Its primary function is to maintain the integrity of connections within the fuel delivery system, which is essential for optimal engine performance.

Fuel Supply Tube

In the context of the fuel supply tube, the Retaining Clamp plays a significant role by securing the tube to the fuel injector. This ensures a consistent and uninterrupted flow of fuel from the supply line to the injector, which is vital for maintaining engine efficiency and performance. The clamp’s ability to provide a tight seal prevents fuel leaks, which could lead to performance issues or safety hazards.

Injector Fuel Supply Tube

Similarly, when applied to the injector fuel supply tube, the Retaining Clamp ensures that the connection between the injector and the fuel supply tube remains secure under various operating conditions. This is particularly important in high-performance engines where fuel delivery precision can significantly impact engine output and reliability.

Injector Plumbing

The Retaining Clamp is also used in injector plumbing to secure various components within the fuel injection system. This includes connections to the fuel rail, injectors, and other plumbing parts. By maintaining these connections, the clamp contributes to the overall stability and performance of the fuel injection system, ensuring that fuel is delivered to the combustion chamber at the correct pressure and timing.

Parts and Performance

In the broader scope of engine parts, the Retaining Clamp is a small yet significant component that contributes to the overall performance of the engine. Its role in securing critical connections within the fuel system ensures that all parts function as intended, leading to improved engine performance, reliability, and longevity.

Plumbing

Lastly, in the context of engine plumbing, the Retaining Clamp is used to secure various plumbing components, ensuring that all connections are tight and secure. This is essential for maintaining the integrity of the fuel system, preventing leaks, and ensuring that fuel is delivered efficiently to the engine. The clamp’s role in plumbing is a testament to its importance in maintaining the overall health and performance of the engine.

Conclusion

The 2830267 Retaining Clamp is a vital component in the operation and maintenance of Cummins engines and commercial trucks. Its role in securing critical components and connections within the fuel system ensures the efficient and reliable operation of the engine. Proper installation, regular maintenance, and understanding its compatibility with various engine models are essential for maximizing the benefits of this part.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Fijalkowski, B. T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.