This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2872074 Retaining Clamp is a component designed for use in commercial truck operations. Its purpose is to secure various parts within the truck’s mechanical system, ensuring they remain in place under operational conditions. The significance of this clamp lies in its contribution to the overall stability and reliability of the truck’s components, which is vital for safe and efficient operation 3.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold components in place. They operate by applying pressure to secure parts, preventing them from moving or vibrating loose during operation. In mechanical systems, retaining clamps play a role in maintaining the integrity and alignment of components, which is important for the system’s performance and longevity 2.

Purpose of the 2872074 Retaining Clamp

The 2872074 Retaining Clamp is specifically designed to secure components within a truck’s system. It ensures that parts remain stable and correctly positioned, which is important for the truck’s operation. By securing components, the clamp helps maintain the alignment and integrity of the mechanical system, contributing to the truck’s overall performance and safety 3.

Key Features

The 2872074 Retaining Clamp features a design that allows for secure attachment to various components. It is constructed from materials that provide durability and resistance to wear and environmental factors. Unique attributes of the clamp include its ease of installation and adjustment, which enhances its functionality in different applications 1.

Benefits of Using the 2872074 Retaining Clamp

Using the 2872074 Retaining Clamp offers several advantages. It contributes to improved safety by ensuring components remain securely in place, reducing the risk of accidents due to part failure. The clamp also enhances reliability by maintaining component alignment and integrity, which is important for consistent truck performance. Additionally, it improves efficiency by simplifying the installation and maintenance processes 3.

Installation Process

Installing the 2872074 Retaining Clamp involves several steps. First, identify the component that requires securing. Then, position the clamp around the component, ensuring it is aligned correctly. Use the appropriate tools to tighten the clamp, applying even pressure to secure the component without over-tightening. Verify the clamp’s position and tightness to confirm proper installation 1.

Common Issues and Troubleshooting

Typical problems with the 2872074 Retaining Clamp may include loosening over time or difficulty in installation. To address these issues, regularly check the clamp’s tightness and re-tighten if necessary. If installation is challenging, ensure the clamp is correctly aligned and that all components are clean and free of debris. Consulting the manufacturer’s guidelines can provide additional troubleshooting steps 3.

Maintenance Tips

To ensure the longevity and optimal performance of the 2872074 Retaining Clamp, regular maintenance is recommended. This includes periodic checks for tightness and alignment, cleaning the clamp and surrounding components to remove dirt and debris, and inspecting for signs of wear or damage. Following these practices helps maintain the clamp’s effectiveness and the truck’s overall performance 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial applications 3.

Compatibility with Cummins Engines

The Retaining Clamp part number 2872074, manufactured by Cummins, is designed to fit a variety of their engine models. This part is crucial for securing components in place, ensuring the engine operates smoothly and efficiently. Below is a detailed overview of the compatibility of this retaining clamp with various Cummins engines:

ISX15 Series

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

These engines are part of the ISX15 series, which are known for their robust performance and reliability. The retaining clamp 2872074 is engineered to fit seamlessly with these models, providing the necessary support and stability.

QSK19 Series

- QSK19 CM2350 K144G

The QSK19 series engines are designed for heavy-duty applications, and the retaining clamp 2872074 is compatible with the QSK19 CM2350 K144G model. This ensures that all components are held securely, contributing to the engine’s overall durability.

QSX15 Series

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX15 series engines are engineered for versatility and efficiency. The retaining clamp 2872074 fits these models, ensuring that all parts remain in their designated positions, which is critical for maintaining engine performance.

X15 Series

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X15 series engines are designed for a range of applications, from construction to transportation. The retaining clamp 2872074 is compatible with these models, providing the necessary support to keep components securely fastened. This compatibility ensures that the engines can handle the rigors of various demanding environments 3.

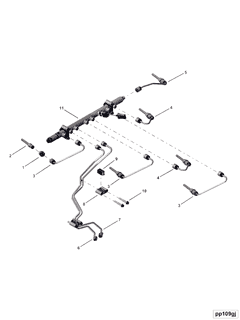

Role of Part 2872074 Retaining Clamp in Engine Systems

The Part 2872074 Retaining Clamp is instrumental in ensuring the secure and efficient operation of various engine components. In the context of an accumulator, this clamp plays a significant role in maintaining the structural integrity and sealing of the accumulator, which is vital for storing and releasing hydraulic fluid under pressure.

When considering the broader spectrum of engine parts, the retaining clamp ensures that components are held firmly in place, reducing the risk of vibrations or movements that could lead to wear or failure. This is particularly important in high-performance engines where precision and reliability are paramount.

In plumbing systems within the engine, the retaining clamp secures connections and fittings, preventing leaks and ensuring that fluid dynamics are maintained as designed. This is essential for the consistent delivery of fuel and other fluids throughout the engine system.

For injectors, the clamp ensures that these components are securely fastened to their mounts. This is important for maintaining the precise alignment and operation of the injectors, which directly impacts fuel delivery and combustion efficiency.

In the XPI JV components and systems, such as the XPI JV System Cummins HD and XPI JV System Scania HD, the retaining clamp is used to secure various high-pressure components. This includes fuel rails, connectors, and other critical parts that operate under significant pressure. The secure fastening provided by the clamp is essential for the reliable performance of these advanced fuel systems.

Overall, the Part 2872074 Retaining Clamp is a fundamental component in maintaining the structural and operational integrity of various engine systems, ensuring that each part functions as intended within the complex network of an engine 2.

Conclusion

The Cummins 2872074 Retaining Clamp is a critical component in the maintenance and operation of commercial truck engines. Its role in securing various parts ensures the stability, reliability, and efficiency of the engine system. Regular maintenance and proper installation are essential to maximize the benefits of this clamp, contributing to the overall performance and safety of the vehicle 3.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ ↩ ↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ ↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.