This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 2881108 Retaining Ring is a component manufactured by Cummins, a well-established name in the commercial vehicle industry. This retaining ring is specifically designed for use in commercial trucks, where it plays a role in securing various components within the vehicle’s mechanical systems. Retaining rings are integral to the functionality and reliability of mechanical assemblies, ensuring that parts remain in their designated positions under operational conditions 1.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They are typically made from spring steel and come in various designs, including internal and external types. The primary function of a retaining ring is to secure components in place, preventing axial movement that could lead to mechanical failure or inefficiency 2.

Purpose of the 2881108 Retaining Ring in Truck Operation

In the context of commercial trucks, the 2881108 Retaining Ring secures specific components within the engine and transmission systems. It ensures that parts such as gears, bearings, and seals remain fixed in their positions, which is vital for the smooth operation and longevity of the truck’s mechanical systems. By maintaining the integrity of these assemblies, the retaining ring contributes to the overall performance and reliability of the vehicle 3.

Key Features of the 2881108 Retaining Ring

The 2881108 Retaining Ring is engineered with specific design and material characteristics to meet the demands of heavy-duty applications. It is typically made from high-tensile steel, which provides the necessary strength and durability to withstand the rigors of commercial truck operation. The ring’s design ensures a secure fit, minimizing the risk of displacement under high stress and vibration conditions.

Benefits of Using the 2881108 Retaining Ring

The use of the 2881108 Retaining Ring offers several advantages in commercial truck applications. It enhances the reliability of mechanical assemblies by ensuring components remain securely in place. The design of the ring also facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, its durability contributes to maintenance efficiency, as it requires less frequent replacement compared to other fastening methods.

Installation Guidelines

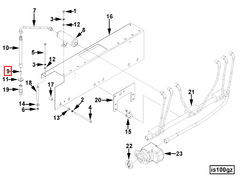

Proper installation of the 2881108 Retaining Ring is crucial for its effectiveness. The process involves using appropriate tools, such as retaining ring pliers, to place the ring in its designated groove without damaging the component or the ring itself. Best practices include ensuring the groove is clean and free of debris before installation and verifying that the ring is seated correctly to prevent any movement of the secured component.

Troubleshooting Common Issues

Common issues with retaining rings include displacement or damage, which can arise from improper installation or operational stress. Troubleshooting these problems involves inspecting the ring and the secured component for signs of wear or misalignment. In cases where the ring has become dislodged or damaged, replacement with a new 2881108 Retaining Ring is recommended to restore the integrity of the mechanical assembly.

Maintenance Tips

Regular inspection and maintenance of the 2881108 Retaining Ring are important for prolonging its service life and ensuring continued performance. This includes checking for signs of wear or corrosion during routine maintenance checks and ensuring that the ring remains securely in place. Addressing any issues promptly can prevent more significant mechanical problems and contribute to the overall reliability of the truck.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial vehicle industry. The company’s commitment to excellence is reflected in its wide range of products, including the 2881108 Retaining Ring, which is designed to meet the high standards of durability and performance expected in heavy-duty applications.

Cummins Retaining Ring 2881108 Compatibility

The Cummins Retaining Ring 2881108 is a critical component designed to fit seamlessly with several engine models, ensuring proper function and longevity of the machinery. This retaining ring is engineered to secure various parts within the engine, maintaining alignment and preventing unwanted movement.

G855 Series

The retaining ring 2881108 is compatible with the G855 engine, a robust and reliable power source. It ensures that internal components remain in their designated positions, contributing to the engine’s overall efficiency and performance.

G855 CM558

Similarly, the G855 CM558 engine also benefits from the use of the 2881108 retaining ring. This model, which includes the CM558 component, relies on the retaining ring to maintain the integrity of its internal mechanisms.

KTA19 Series

The retaining ring 2881108 is also suitable for the KTA19GC engine. This engine, known for its durability and power, uses the retaining ring to secure various parts, ensuring smooth operation and reducing the risk of mechanical failure.

KTA19GC CM558

The KTA19GC CM558 engine, which incorporates the CM558 component, is another model that utilizes the 2881108 retaining ring. This part plays a crucial role in maintaining the alignment and stability of the engine’s internal parts.

KTA38GC CM558

The KTA38GC CM558 engine, another variant in the KTA series, also requires the 2881108 retaining ring. This part is essential for securing components within the engine, ensuring that they remain in their correct positions and function as intended.

N14 Series

Lastly, the N14 G engine is another model that is compatible with the 2881108 retaining ring. This engine, known for its reliability and performance, uses the retaining ring to maintain the alignment and stability of its internal components, contributing to its overall efficiency and longevity.

Role of Part 2881108 Retaining Ring in Engine Systems

The part 2881108 retaining ring is integral to the secure functioning of several components within engine systems. In the context of a spark plug extension, the retaining ring ensures that the extension remains firmly in place, preventing any unwanted movement that could lead to misfires or inefficient combustion. This stability is essential for maintaining consistent spark delivery to the combustion chamber.

Within the ignition system, the retaining ring plays a significant role by securing various components such as the ignition coil or distributor cap. By holding these parts in the correct position, the ring helps to ensure reliable electrical connections and consistent spark generation. This is particularly important in high-performance engines where precision and reliability are paramount.

Overall, the part 2881108 retaining ring contributes to the durability and efficiency of engine systems by providing necessary support and stability to critical components.

Conclusion

The 2881108 Retaining Ring is a vital component in the maintenance and operation of commercial trucks, ensuring the secure positioning of critical engine and transmission parts. Its design and material characteristics are tailored to withstand the demanding conditions of heavy-duty applications, contributing to the reliability and performance of the vehicle. Proper installation, regular maintenance, and prompt troubleshooting of issues are essential practices to maximize the effectiveness of this Cummins part.

-

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISBe2 and ISBe3 CM850. Bulletin Number 4021680.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.