This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2899540 Retaining Ring is a specialized component designed for use in heavy-duty truck applications. Its purpose is to secure specific parts within the truck’s engine system, ensuring they remain in place under various operating conditions. The significance of this retaining ring lies in its ability to maintain the integrity and efficiency of the engine components it supports.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They function by fitting into a groove and exerting a radial force that keeps the component in position. Retaining rings are widely used in various mechanical systems to secure bearings, gears, and other parts, ensuring they operate correctly and efficiently 3.

Purpose of the 2899540 Retaining Ring

The Cummins 2899540 Retaining Ring plays a specific role in the operation of heavy-duty trucks by securing components within the engine system. It is designed to hold parts such as bearings or gears in place, preventing them from shifting or dislodging during engine operation. This ensures the smooth and reliable functioning of the engine, contributing to overall vehicle performance and durability.

Key Features

The Cummins 2899540 Retaining Ring is crafted from high-quality materials, typically steel or stainless steel, to ensure durability and resistance to wear. Its design specifications include precise dimensions and a robust construction that allows it to withstand the high stresses and temperatures encountered in heavy-duty truck engines. Unique attributes such as corrosion resistance and a secure fit enhance its performance and longevity.

Benefits

Using the Cummins 2899540 Retaining Ring offers several advantages. It improves the reliability of the engine components it secures, leading to enhanced overall performance of the truck. Additionally, by ensuring parts remain in place, it can help prevent costly repairs and downtime, providing potential cost savings over time. The ring’s durable construction also contributes to its long service life, further adding to its value 1.

Installation Process

Proper installation of the Cummins 2899540 Retaining Ring is crucial for its effective function. The process involves using appropriate tools, such as retaining ring pliers, to place the ring into the designated groove on the shaft or housing. It is important to ensure the ring is correctly aligned and seated to provide a secure hold on the component. Following manufacturer guidelines and best practices during installation helps ensure the ring performs as intended.

Troubleshooting and Maintenance

Common issues with retaining rings may include displacement, corrosion, or wear. Regular inspection and maintenance can help identify problems early, allowing for timely replacement or repair. Keeping the ring and its surrounding components clean and free from debris can prolong its lifespan. Additionally, ensuring proper installation and using the correct retaining ring for the application can prevent many issues 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry for producing reliable and high-performance components. Their product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Role of Part 2899540 Retaining Ring in Engine Systems

In the intricate design of engine systems, the Part 2899540 Retaining Ring serves a critical function by ensuring the secure placement and operation of various components. This retaining ring is instrumental in maintaining the integrity and performance of the engine by holding components in their designated positions, thereby facilitating smooth and efficient engine operation.

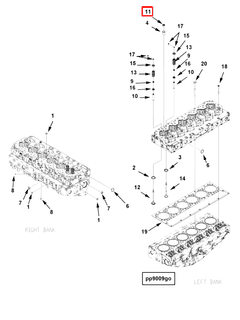

Cylinder Head Assembly

Within the cylinder head assembly, the retaining ring plays a significant role. It secures the cylinder head to the engine block, ensuring a tight seal that is vital for maintaining compression and preventing leaks. This seal is fundamental for the efficient combustion process, directly influencing the engine’s performance and longevity 3.

Cylinder Top Level Assembly Head

In the cylinder top level assembly head, the retaining ring is used to secure various components, such as sensors and valves, in place. This ensures that these components operate within their designed parameters, contributing to the overall efficiency and reliability of the engine. The precise positioning afforded by the retaining ring is essential for the optimal functioning of the cylinder top level assembly head.

Piston Cooling Nozzle

The retaining ring is also utilized in the assembly of the piston cooling nozzle. By securing the nozzle in place, it ensures that the cooling process is consistent and effective. This is particularly important in high-performance engines where maintaining optimal operating temperatures is crucial for performance and durability.

General Component Performance

Across various engine components, the retaining ring’s role in securing parts is fundamental to the performance and durability of the engine. It ensures that all components are held in their correct positions, allowing for the smooth operation of the engine. This not only enhances the engine’s performance but also contributes to its longevity by reducing wear and tear on moving parts.

Conclusion

The Cummins 2899540 Retaining Ring is a key component in the assembly and operation of engine systems. Its role in securing various components ensures the engine operates efficiently and reliably, directly impacting the performance and durability of the engine.

-

Ferrari, Alessandro, and Pietro Pizzo. Injection Technologies: Mixture Formation Strategies. SAE International, 2022.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ -

Wang, Yushu. Introduction to Engine Valvetrains. SAE International, 2007.

↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.