This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

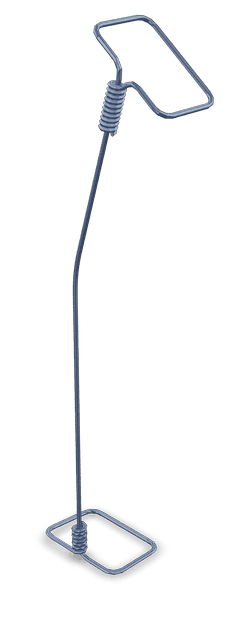

The Cummins 3001518 Retaining Wire is a specialized component designed for use in heavy-duty truck maintenance and operation. This retaining wire serves a significant role in ensuring the secure attachment of various components within the truck’s mechanical systems. Understanding its purpose and functionality is key to maintaining the efficiency and reliability of heavy-duty trucks.

Basic Concepts of Retaining Wires

Retaining wires are mechanical fasteners used to secure components in place within various systems. They function by wrapping around parts and tightening to hold them securely. In mechanical systems, retaining wires prevent components from loosening due to vibrations or other dynamic forces, thereby ensuring the integrity and performance of the system 1.

Purpose of the 3001518 Retaining Wire

The Cummins 3001518 Retaining Wire is specifically designed to secure components within a truck’s engine and transmission systems. It plays a role in maintaining the proper alignment and connection of parts such as sensors, brackets, and other critical components. By ensuring these parts remain in place, the retaining wire contributes to the overall stability and performance of the truck 2.

Key Features

The Cummins 3001518 Retaining Wire is characterized by several key features that enhance its performance. It is made from a durable material that offers high tensile strength, allowing it to withstand the stresses of heavy-duty truck operation. The wire’s flexibility enables it to conform to the shapes of the components it secures, providing a snug and effective hold. Additionally, its design includes features that facilitate easy installation and adjustment 3.

Benefits of Using the 3001518 Retaining Wire

Utilizing the Cummins 3001518 Retaining Wire offers several advantages. Its robust construction and secure hold improve the reliability of the components it fastens, leading to enhanced durability of the truck’s mechanical systems. This, in turn, contributes to more efficient truck operations, reducing the likelihood of unexpected downtime due to component failure 4.

Installation Guidelines

Proper installation of the Cummins 3001518 Retaining Wire involves several steps to ensure secure and effective placement. Begin by identifying the components that require fastening. Use appropriate tools, such as wire twisters and tensioners, to wrap the wire around the components. Ensure the wire is tight enough to hold the parts securely without over-tightening, which could damage the components or the wire itself. Follow best practices for wire routing to avoid interference with other parts and to maintain a clean and organized engine compartment.

Troubleshooting Common Issues

Common problems with retaining wires include loosening, corrosion, and damage. To address these issues, regularly inspect the wires for signs of wear or corrosion. If a wire appears loose, re-tighten it or replace it if necessary. In cases of corrosion, clean the affected area and consider applying a protective coating to prevent further corrosion. Damaged wires should be replaced to maintain the security of the components they hold.

Maintenance Tips

To ensure the long-term performance and reliability of the Cummins 3001518 Retaining Wire, conduct regular maintenance checks. Inspect the wires during routine engine and transmission maintenance to look for signs of wear, corrosion, or damage. Clean the wires and their surrounding areas to remove any debris that could affect their performance. Following these maintenance tips will help prolong the life of the retaining wires and the components they secure.

Safety Considerations

When working with retaining wires, it is important to observe safety guidelines and precautions. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against injuries from sharp edges or flying debris. Handle the wires carefully to avoid cuts or abrasions. Follow proper installation and maintenance practices to ensure the wires are securely fastened and do not pose a risk of injury or component failure.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a strong reputation in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and expertise make it a trusted partner for businesses and individuals seeking reliable and efficient power solutions.

Cummins Retaining Wire Part 3001518 Compatibility

The Cummins Retaining Wire part 3001518 is designed to fit seamlessly with a variety of engine models, ensuring secure and reliable performance. This part is engineered to meet the specific needs of the following engines:

- K38

- K50

- M11 CELECT PLUS

- N14 MECHANICAL

For the K38 and K50 engines, the retaining wire plays a crucial role in maintaining the integrity of the engine’s internal components. Its precision design ensures that it fits perfectly within the engine’s architecture, providing the necessary support and stability.

In the M11 CELECT PLUS and N14 MECHANICAL engines, the retaining wire is equally vital. These engines benefit from the part’s ability to withstand high stress and pressure, ensuring that all moving parts remain securely in place. The compatibility of part 3001518 with these engines is a testament to Cummins’ commitment to quality and reliability.

Additionally, the retaining wire is also compatible with the NH/NT 855 and V28 engines, further expanding its utility across a range of engine types. This versatility makes it an essential component for maintaining the operational efficiency of these engines.

By ensuring a precise fit and reliable performance, the Cummins Retaining Wire part 3001518 is a critical component for the longevity and efficiency of the engines it supports.

Role of Part 3001518 Retaining Wire in Engine Systems

The 3001518 Retaining Wire is an essential component in securing various parts within engine systems, ensuring stability and proper function of the assembly. Its applications span across multiple components, each playing a significant role in the engine’s performance and efficiency.

Air Silencer Mounting

In the air silencer mounting, the 3001518 Retaining Wire is used to secure the silencer to the engine frame. This ensures that the silencer remains in the correct position, reducing noise emissions and maintaining the integrity of the air intake system.

Exhaust Accessory

For exhaust accessories, the retaining wire helps in securing components that are part of the exhaust system. This includes clamps and brackets that hold the exhaust pipes in place, ensuring they do not shift or vibrate excessively during operation.

Exhaust Manifold

In the exhaust manifold, the 3001518 Retaining Wire is employed to secure the manifold to the engine block. This is vital for maintaining the seal between the manifold and the engine, preventing exhaust leaks that could affect performance and emissions.

Exhaust Manifold and Turbocharger Mounting

When mounting the exhaust manifold alongside a turbocharger, the retaining wire plays a key role in securing both components. This ensures that the turbocharger remains aligned with the exhaust manifold, optimizing exhaust flow and turbocharger efficiency.

Flange Insul Cover

The flange insul cover, which protects the flange from heat and wear, is secured using the 3001518 Retaining Wire. This ensures that the cover stays in place, providing consistent protection and insulation for the flange.

Heat Shield

Heat shields are critical for protecting nearby components from the high temperatures generated by the exhaust system. The retaining wire is used to secure these shields, ensuring they remain effective in their protective role.

Silencer Mounting

Similar to the air silencer, the silencer mounting for the exhaust system utilizes the retaining wire to secure the silencer. This is important for reducing noise and ensuring the silencer does not move out of position.

Turbo Location

At the turbo location, the retaining wire is used to secure various components of the turbocharger, such as the turbine housing and compressor housing. This ensures that the turbocharger remains stable and aligned, enhancing its performance.

Turbocharger

The turbocharger itself benefits from the use of the 3001518 Retaining Wire in securing its various parts, including the turbocharger casing cover and turbocharger cover. This ensures that all components remain in their intended positions, optimizing turbocharger function.

Turbocharger Arrangement

In the turbocharger arrangement, where multiple turbochargers may be used in parallel or series, the retaining wire is essential for securing each turbocharger in its designated location. This maintains the overall efficiency and balance of the turbocharger system.

Turbocharger Assembly

The turbocharger assembly, which includes the turbocharger, intercooler, and associated piping, relies on the retaining wire to keep all components securely in place. This is important for the overall performance and durability of the assembly.

Turbocharger Casing Cover

The turbocharger casing cover, which protects the internals of the turbocharger, is secured using the retaining wire. This ensures that the cover remains intact, protecting the turbocharger from debris and damage.

Turbocharger Cover

Similarly, the turbocharger cover is held in place by the retaining wire, ensuring that it provides consistent protection for the turbocharger’s internal components.

Turbocharger Location

At the turbocharger location, the retaining wire is used to secure the turbocharger to the engine and exhaust system. This ensures that the turbocharger operates within the correct parameters, enhancing engine performance.

Turbocharger Mounting

The turbocharger mounting process extensively uses the 3001518 Retaining Wire to secure the turbocharger to the engine block or exhaust manifold. This is essential for maintaining the turbocharger’s alignment and stability during operation.

Turo Location

Finally, at the turo location (likely a typo for “turbo location”), the retaining wire ensures that all turbocharger-related components are securely fastened, contributing to the overall efficiency and reliability of the engine system.

Conclusion

The Cummins 3001518 Retaining Wire is a critical component in the maintenance and operation of heavy-duty trucks. Its robust design, compatibility with various engine models, and versatile applications across engine systems make it an indispensable part for ensuring the stability, performance, and reliability of heavy-duty truck engines. Regular maintenance, proper installation, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Denton, Tom and Pells, Hayley. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.