This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

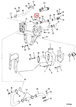

The Cummins 3002957 Retaining Clamp is a component designed to secure various parts within the operational systems of commercial trucks. Its role is significant in maintaining the integrity and efficiency of truck operations by ensuring that components remain in place under various conditions.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold components securely in place. They are integral in systems where vibration or movement could dislodge parts, potentially leading to malfunctions or failures. These clamps function by applying consistent pressure to the components they secure, which helps in maintaining alignment and operational stability 1.

Purpose of the 3002957 Retaining Clamp

The Cummins 3002957 Retaining Clamp is specifically designed to secure components within the truck’s engine and transmission systems. It plays a role in ensuring that parts such as hoses, pipes, and electrical cables remain firmly in place, which is vital for the consistent operation of the vehicle. By securing these components, the clamp contributes to the overall reliability and safety of the truck 2.

Key Features

The 3002957 Retaining Clamp is constructed from durable materials that offer resistance to corrosion and wear, ensuring longevity in demanding environments. Its design includes features such as adjustable bands and secure locking mechanisms, which allow for a custom fit around various components. These characteristics enhance its functionality by providing a stable and reliable hold 3.

Benefits of Using the 3002957 Retaining Clamp

Utilizing the Cummins 3002957 Retaining Clamp offers several advantages. It enhances safety by preventing components from dislodging, which could lead to operational disruptions or accidents. Additionally, it improves efficiency by ensuring that all secured parts function as intended without unnecessary wear or movement. The reliability of the clamp also contributes to reduced maintenance needs and increased uptime for commercial trucks 4.

Installation Process

Installing the Cummins 3002957 Retaining Clamp involves several steps to ensure proper securing of components. First, identify the component that requires clamping. Then, position the clamp around the component, ensuring it is aligned correctly. Use the provided tools to adjust the clamp to the appropriate size and secure it in place. Finally, verify that the clamp is firmly in place and that the component is held securely without any undue stress 5.

Troubleshooting Common Issues

Common issues with the Cummins 3002957 Retaining Clamp may include loosening over time due to vibrations or wear. To address these problems, regular inspections are recommended to ensure the clamp remains secure. If loosening is detected, re-tighten the clamp or replace it if necessary. Additionally, checking for signs of wear or corrosion can help in maintaining the clamp’s effectiveness .

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3002957 Retaining Clamp, regular maintenance is advised. This includes periodic inspections for signs of wear, corrosion, or loosening. Cleaning the clamp and its surrounding area can prevent buildup that might affect its functionality. Additionally, ensuring that all secured components are in good condition will contribute to the overall effectiveness of the clamp .

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Cummins Retaining Clamp 3002957 Compatibility

The Cummins Retaining Clamp part number 3002957 is designed to fit a variety of engine models, ensuring secure fastening and reliable performance across multiple applications. Here is a detailed overview of its compatibility with the listed engines:

K Series Engines

- K19

- K38

- K50

The retaining clamp is suitable for these K series engines, providing a robust solution for securing components in these models.

KTA Series Engines

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

These KTA series engines benefit from the retaining clamp’s precision fit and durability, ensuring that critical components remain securely fastened.

QSK Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QSK60 CM500

- QSK60G

- QSK78 CM500

The retaining clamp is compatible with a wide range of QSK series engines, including those with various CM and MCRS configurations. This ensures that the clamp can be used across different engine variants within the QSK series.

This compatibility ensures that the retaining clamp can be used across a broad spectrum of Cummins engines, providing a reliable solution for securing components in these models.

Role of Part 3002957 Retaining Clamp in Engine Systems

The Part 3002957 Retaining Clamp is an essential component in securing and maintaining the integrity of various engine systems. Its application spans across multiple subsystems, ensuring efficient operation and longevity of the engine.

Manifold Systems

In manifold systems, the Retaining Clamp plays a significant role in securing the manifold to the engine block. This ensures a tight seal, preventing any leaks that could affect engine performance. The clamp’s reliable hold is vital for maintaining consistent airflow and pressure within the manifold, which directly influences combustion efficiency and overall engine output.

Water Plumbing

For water plumbing within the engine, the Retaining Clamp is used to secure hoses and pipes that circulate coolant. This is important for thermal management, as it ensures that coolant flows smoothly without any disruptions. The clamp helps in maintaining the structural integrity of the plumbing, reducing the risk of leaks that could lead to overheating or engine damage.

Cabin Heater System

In the cabin heater system, the Retaining Clamp is employed to secure connections between the heater core and the coolant lines. This ensures that the heater operates efficiently by maintaining a consistent flow of hot coolant. The clamp’s role here is to provide a secure connection that withstands the varying temperatures and pressures within the system.

Auxiliary Cooling Systems

For auxiliary cooling systems, such as those used in high-performance engines or heavy-duty applications, the Retaining Clamp is crucial in securing additional cooling lines and components. This includes oil coolers, transmission coolers, and other heat exchangers. The clamp ensures that these systems remain intact under high stress, contributing to the overall reliability and performance of the engine.

Integrated System Functionality

Across all these applications, the Part 3002957 Retaining Clamp contributes to the seamless integration of various engine systems. By providing a secure and reliable connection point, it allows these systems to function as intended, enhancing the engine’s efficiency, durability, and performance.

Conclusion

The Cummins 3002957 Retaining Clamp is a vital component in the maintenance and operation of commercial truck engines. Its design and functionality ensure that critical components remain securely in place, contributing to the overall efficiency, reliability, and safety of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this part.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSG12/X12 CM2350 G110. Bulletin Number 4367322.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.