This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

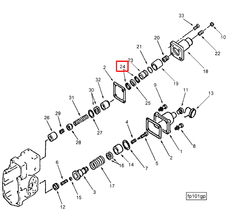

Introduction to Retaining Rings

Retaining rings, also known as circlips or snap rings, are essential components in mechanical assemblies, particularly within engines and transmissions. These rings are designed to secure components in place, preventing axial or radial movement. Typically made from materials such as stainless steel, carbon steel, or beryllium copper, retaining rings are chosen for their durability and resistance to wear, ensuring longevity in demanding applications 1.

Functionality of Retaining Rings

The primary function of retaining rings is to create a clamping force between two or more parts. They are installed into a groove on the shaft or within a housing, and their design allows them to expand and contract as needed. There are two main types of retaining rings: internal and external. Internal retaining rings fit into a groove on the outside of a shaft, while external retaining rings fit into a groove within a housing or bore. This design ensures that components remain securely in place under various operational conditions 2.

The Role of Cummins 3026017 Retaining Ring in Truck Engines

The Cummins 3026017 retaining ring is specifically engineered for use in heavy-duty truck engines. This retaining ring ensures that critical components, such as gears, bearings, and pulleys, remain securely in place, preventing movement that could lead to mechanical failure. By maintaining the integrity of these components, the retaining ring significantly contributes to the overall reliability and performance of the engine 3.

Importance in Engine Operation

In the context of a truck engine, the 3026017 retaining ring plays a vital role in maintaining the alignment and stability of rotating parts. This is particularly crucial under heavy-load conditions, where the forces exerted on engine components can be substantial. Proper installation and maintenance of retaining rings like the Cummins 3026017 are essential to prevent catastrophic engine failure, ensuring the longevity and efficiency of the engine 4.

Troubleshooting and Maintenance

Regular inspection and maintenance of retaining rings are crucial to prevent unexpected failures. Here are some tips for troubleshooting and maintaining retaining rings:

- Visual Inspection: Check for signs of wear, deformation, or damage. A retaining ring that appears bent or broken should be replaced immediately.

- Proper Installation: Ensure that the retaining ring is correctly installed in its designated groove. Incorrect installation can lead to premature failure.

- Lubrication: While retaining rings are not typically lubricated, ensuring that the surrounding components are well-lubricated can help reduce wear on the retaining ring.

- Replacement: Follow the manufacturer’s recommendations for replacing retaining rings. Over time, even well-maintained retaining rings will wear out and should be replaced to prevent engine damage.

Cummins: A Leader in Engine Manufacturing

Cummins is a globally recognized leader in the design and manufacture of engines and related technologies. With a legacy of innovation and quality, Cummins products are trusted by professionals in the commercial truck industry. The Cummins 3026017 retaining ring exemplifies the company’s commitment to providing high-quality, reliable components that meet the demanding needs of heavy-duty applications.

Role of Part 3026017 Retaining Ring in Engine Systems

The Cummins part 3026017, a Retaining Ring, is a critical component in ensuring the proper functionality and longevity of various engine systems. This part is designed to fit seamlessly with the L10 MECHANICAL, N14 MECHANICAL, and NH/NT 855 engines.

For the L10 MECHANICAL and N14 MECHANICAL engines, the retaining ring plays a vital role in securing certain components within the engine. It ensures that parts such as bearings and shafts remain in their designated positions, preventing any unwanted movement that could lead to mechanical failure.

In the NH/NT 855 engine, the retaining ring is equally important. It is used to secure various rotating components, maintaining the integrity of the engine’s internal mechanisms. This is crucial for the engine’s overall performance and reliability.

The compatibility of the retaining ring across these engines highlights its universal design and the importance of using the correct part for each specific engine model. Ensuring that the retaining ring is properly installed is essential for maintaining the engine’s operational efficiency and preventing potential mechanical issues.

Conclusion

Understanding the role and maintenance of the Cummins 3026017 retaining ring is essential for engineers, mechanics, truck drivers, and fleet operators. By ensuring that this critical component is properly installed and maintained, professionals can help extend the life of their engines and maintain the reliability of their commercial trucks.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2880 X138B. Bulletin Number 5613140.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.