3049995

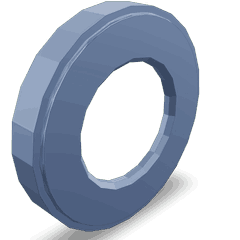

Injector Spring Retainer

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Spring Retainer, part number 3049995, is a critical component in the fuel injection system of Cummins engines, commonly used in heavy-duty trucks. This part secures the injector spring, ensuring the precise operation of the fuel injection process. Its role is vital for maintaining the accuracy and reliability of fuel delivery, which directly impacts engine performance, efficiency, and emissions control 1.

Function and Operation

The Injector Spring Retainer functions by holding the injector spring firmly against the injector nozzle. This ensures the proper opening and closing of the injector nozzle, affecting the timing and pressure of fuel injection. The consistent force applied by the spring, secured by the retainer, allows for precise control over the injection process, essential for optimal combustion and engine performance 2.

Key Features

This Cummins part is designed with high-quality materials to withstand the high pressures and temperatures within the fuel injection system. Its precision-machined design ensures a secure fit and consistent performance. The retainer is specifically engineered for compatibility with Cummins engines, ensuring reliable operation and seamless integration 3.

Role in Truck Operation

In heavy-duty trucks, the Injector Spring Retainer ensures proper fuel injection timing and pressure. This contributes to the engine’s overall performance, including power output, fuel efficiency, and emissions control. The consistent and precise fuel delivery facilitated by the retainer is crucial for efficient engine operation under various load conditions.

Benefits

The Injector Spring Retainer offers several advantages, including improved engine reliability due to its durable construction and precise engineering. It also helps minimize maintenance requirements, allowing for extended periods between servicing. Additionally, the use of this component enhances overall engine performance, including better fuel efficiency and reduced emissions.

Troubleshooting and Maintenance

Regular inspection and maintenance of the fuel injection system are important for identifying common issues related to the Injector Spring Retainer, such as leaks or malfunctions. Recommended practices include checking for signs of wear or damage, ensuring proper installation, and replacing the retainer if necessary to maintain system integrity and performance.

Cummins Overview

Cummins Inc. is a global leader in diesel and alternative fuel engines, with a reputation for innovation, quality, and reliability. The company’s commitment to advancing engine technology is evident in its high-quality components, such as the Injector Spring Retainer, which enhance the performance and efficiency of heavy-duty trucks.

Compatibility

The Injector Spring Retainer, part 3049995, is compatible with various Cummins engine models, including the L10 MECHANICAL engine. Its precise fit and reliable performance make it essential for maintaining the integrity of the fuel injection system in these engines.

Integration with Injectors

This part is pivotal in the operation of fuel injectors, securing the spring within the injector to control the opening and closing of the injector nozzle. This precise control is vital for the accurate delivery of fuel into the combustion chamber, directly influencing engine performance and fuel efficiency.

Contribution to Injector Mounting

In injector mounting, the Injector Spring Retainer helps maintain the structural integrity of the injector assembly by keeping the spring in place. This stability is important for the consistent operation of the injector, especially under varying engine loads and speeds.

Role in Emissions Rebuild Kits

The Injector Spring Retainer is a key component in emissions rebuild kits. It ensures that the injectors operate within specified parameters, which is essential for meeting emissions standards. The retainer’s role in maintaining the integrity of the injector spring directly impacts the engine’s emissions output.

Impact on Overall Engine Performance

The efficiency of the fuel injection system significantly influences engine performance. The Injector Spring Retainer contributes to this by ensuring the proper function of the injector spring, aiding in achieving a more precise fuel-air mixture, which is fundamental for power output, fuel economy, and emissions control.

Significance in Performance Parts

In performance parts, the Injector Spring Retainer plays an indispensable role. High-performance engines demand components that can withstand greater stresses and deliver consistent performance. The retainer’s ability to maintain spring integrity under these conditions is a contributing factor to the engine’s enhanced performance capabilities.

Conclusion

The Injector Spring Retainer (part 3049995) is a fundamental component in the fuel injection system of an engine. Its interaction with injectors, role in injector mounting, contribution to emissions control, and impact on engine performance and efficiency underscore its importance in both standard and high-performance engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.