This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Diaphragm Retainer 3054405, manufactured by Cummins, is a component designed to enhance the operational efficiency of commercial trucks. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-quality parts that contribute to the smooth functioning of heavy-duty vehicles. This part is integral to maintaining the performance and reliability of truck engines, playing a significant role in various engine systems.

Basic Concepts and Functionality

Diaphragm retainers are components that help manage the movement and positioning of diaphragms within an engine system. They operate by securing the diaphragm in place, ensuring it functions correctly under varying conditions. This is particularly important in systems where precise control and stability are required to maintain engine efficiency and performance. The Diaphragm Retainer 3054405 is engineered to perform these functions with high reliability, contributing to the overall effectiveness of the truck’s engine system 1.

Purpose of the Diaphragm Retainer 3054405

This Cummins part is designed to hold the diaphragm in the correct position within the engine system. This ensures that the diaphragm can operate efficiently, which is vital for maintaining system integrity and performance. By securing the diaphragm, the retainer helps to prevent issues that could arise from improper positioning, such as leaks or reduced efficiency. This component plays a role in ensuring that the engine system operates smoothly and reliably 2.

Key Features

The Diaphragm Retainer 3054405 boasts several key features that enhance its effectiveness and reliability. These include a robust design that can withstand the demanding conditions of commercial truck operations, precise engineering to ensure accurate diaphragm positioning, and materials that offer durability and resistance to wear. These features contribute to the component’s ability to perform reliably over time, making it a valuable part of the engine system 3.

Benefits

The use of the Diaphragm Retainer 3054405 offers several advantages. It contributes to improved engine efficiency by ensuring that the diaphragm operates correctly. This can lead to better overall performance of the truck. Additionally, the durability of the retainer means that it can withstand the rigors of commercial use, reducing the need for frequent replacements. Ease of maintenance is another benefit, as the design of the retainer allows for straightforward installation and replacement procedures.

Installation and Compatibility

Proper installation of the Diaphragm Retainer 3054405 is crucial for ensuring optimal performance. It is important to follow the manufacturer’s guidelines for installation to ensure that the component is correctly positioned and secured. Compatibility with various truck models and engine types is a key consideration, as this ensures that the retainer can be used across a wide range of applications. Adhering to these guidelines helps to maintain the integrity and performance of the engine system.

Troubleshooting and Maintenance

Identifying common issues related to the Diaphragm Retainer 3054405 can help in maintaining its performance and longevity. Regular inspections for signs of wear or damage are recommended, as these can indicate the need for maintenance or replacement. Diagnostic procedures should be followed to accurately assess the condition of the retainer. Recommended maintenance practices include cleaning the component and ensuring that it is securely installed. These steps help to prolong the lifespan of the retainer and ensure consistent performance.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a reputation for producing high-quality components. The company has a long history of innovation and commitment to excellence, which is reflected in its product line. Cummins is known for its dedication to producing parts that meet the demanding requirements of commercial truck operations. The Diaphragm Retainer 3054405 is a testament to this commitment, offering reliability and performance in a critical engine component.

Cummins Diaphragm Retainer Part 3054405 Compatibility

This Cummins part is designed to fit seamlessly with several Cummins engine models, providing a reliable and efficient solution for maintaining the integrity of the diaphragm system.

K19, K38, and K50 Engines

This part is compatible with the K19, K38, and K50 engines. These engines are known for their robust design and performance, and the diaphragm retainer plays a role in maintaining the air pressure and fuel efficiency of these models.

N14 MECHANICAL Engine

The N14 MECHANICAL engine also benefits from the use of the Cummins part 3054405. This engine is widely used in various applications, including heavy-duty trucks and industrial machinery. The diaphragm retainer is a key component in this engine, helping to maintain the air pressure and fuel efficiency that the N14 MECHANICAL engine is known for.

NH/NT 855 Engines

The NH/NT 855 engines are another series where the Cummins part 3054405 is a perfect fit. These engines are designed for durability and efficiency, and the diaphragm retainer is an essential part of this design.

Role of Part 3054405 Diaphragm Retainer in Engine Systems

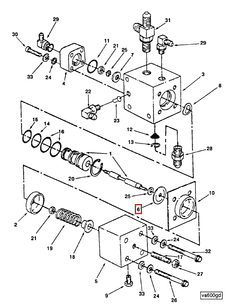

The Diaphragm Retainer, part 3054405, is a versatile component that enhances the functionality and reliability of various engine systems by securely holding diaphragms in place. Its integration with the following components highlights its significance:

- Aftercooler Plumbing: The Diaphragm Retainer aids in maintaining the integrity of the aftercooler system by ensuring that the diaphragm within the system remains securely in place.

- Base Parts: When integrated with base parts, the Diaphragm Retainer contributes to the structural stability of the engine.

- Camshaft and Cylinder Head: In systems where the camshaft and cylinder head incorporate diaphragm-operated mechanisms, the Diaphragm Retainer plays a role in securing these diaphragms.

- Cylinder Head Mounting: The secure mounting of the cylinder head is paramount for engine operation. The Diaphragm Retainer, when used in conjunction with cylinder head components, assists in maintaining the position of any diaphragms involved in the mounting process.

- EBM: Device and Performance Parts: In Enhanced Brake Modules (EBM) and performance parts, the Diaphragm Retainer is instrumental in securing diaphragms that are part of these advanced systems.

- Timing Control: Accurate timing is essential for engine performance. The Diaphragm Retainer, when used in timing control systems, helps in securing diaphragms that are part of the timing mechanism.

- Hydro-Mechanical Step and Oil Control Valves: In systems that utilize hydro-mechanical steps and oil control valves, the Diaphragm Retainer is key in securing diaphragms that control oil flow and pressure.

- Injectors and Pressure Regulator Valve: The Diaphragm Retainer also plays a role in securing diaphragms within injectors and pressure regulator valves.

- Oil Manifold and Connection: In oil manifolds and connections, the Diaphragm Retainer ensures that diaphragms remain in place, facilitating the smooth and controlled flow of oil throughout the engine.

Conclusion

In summary, the Diaphragm Retainer 3054405 is a critical component that enhances the functionality and reliability of various engine systems by securely holding diaphragms in place. Its role in these systems underscores the importance of precise component interaction for optimal engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.