This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3103225 Retaining Ring is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners that secure components within a housing, preventing them from moving out of position. They operate by fitting into a groove and exerting pressure against the inner diameter of the housing. This mechanism ensures that parts remain in place under operational conditions, which is vital for the integrity and functionality of mechanical systems 1.

Purpose of the Cummins 3103225 Retaining Ring

The Cummins 3103225 Retaining Ring is utilized in various components of commercial trucks to secure parts that are subject to movement or vibration. Its application can be found in areas such as the engine, transmission, and other critical systems where maintaining the position of components is necessary for proper function. By securing these parts, the retaining ring contributes to the stability and reliability of the truck’s operation 2.

Key Features

The Cummins 3103225 Retaining Ring is characterized by its material composition, typically made from high-strength steel to withstand the rigors of truck operation. Its design includes a coiled shape that allows it to be compressed for installation and then expand to grip the groove securely. This design ensures a snug fit and reliable retention of components 3.

Benefits

The use of the Cummins 3103225 Retaining Ring offers several advantages. It enhances the reliability of truck components by ensuring they remain in the correct position. Its durable construction contributes to the longevity of the parts it secures, and by maintaining component alignment, it can improve the efficiency of truck operations 4.

Installation Process

Installing the Cummins 3103225 Retaining Ring requires the use of appropriate tools, such as retaining ring pliers, to compress and position the ring within the designated groove. It is important to follow manufacturer guidelines for installation to ensure the ring is fitted correctly and exerts the proper pressure for secure retention 5.

Common Issues and Troubleshooting

Issues with retaining rings can include wear due to operational stress or improper installation leading to insufficient retention. Troubleshooting may involve inspecting the ring for signs of damage or deformation and ensuring it is correctly seated in the groove. Replacement may be necessary if the ring is found to be compromised 6.

Maintenance Tips

Regular maintenance of the Cummins 3103225 Retaining Ring involves periodic inspection for signs of wear or damage. It is advisable to follow the manufacturer’s recommendations for inspection intervals and to replace the ring if any deterioration is observed to prevent component failure 7.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftermarket parts. With a strong reputation in the automotive industry, Cummins is committed to quality and innovation, providing reliable components that contribute to the performance and durability of commercial vehicles 8.

ISM CM570/870 Engine Compatibility with Retaining Ring Part 3103225

The retaining ring part number 3103225, manufactured by Cummins, is a critical component in the ISM CM570/870 engine series. This part is designed to secure various engine components, ensuring they remain in place and function correctly.

In the ISM CM570 engine, the retaining ring part 3103225 is used to secure the crankshaft pulley, which is essential for the proper operation of the engine’s timing system. This ensures that the engine’s internal components, such as the camshaft and valves, operate in synchronization.

Similarly, in the ISM CM870 engine, the retaining ring part 3103225 plays a crucial role in securing the crankshaft damper. This component helps to reduce vibrations and maintain the smooth operation of the engine. The retaining ring ensures that the damper remains securely attached to the crankshaft, preventing any potential movement that could lead to engine imbalance.

Both engines in the ISM CM570/870 series rely on the retaining ring part 3103225 to maintain the integrity of their respective crankshaft systems. This part is essential for the longevity and performance of the engines, as it helps to prevent wear and tear on the crankshaft and related components 9.

Role of Part 3103225 Retaining Ring in Engine Systems

The part 3103225 retaining ring is an essential component in various engine systems, ensuring the secure assembly and operation of multiple parts. Its application spans across different components, contributing to the overall efficiency and reliability of the engine.

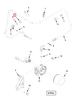

Turbocharger Integration

In turbocharger systems, the retaining ring plays a significant role in maintaining the integrity of the turbocharger’s internal components. It secures the turbine wheel within the housing, preventing any unwanted movement that could lead to imbalance or failure. This ensures that the turbocharger operates smoothly, enhancing the engine’s performance by providing consistent boost pressure 10.

Air Filter Assembly

Within the air filter assembly, the retaining ring is used to hold the filter element in place. This is vital for maintaining the correct airflow through the filter, ensuring that only clean air reaches the engine. Proper filtration is key to preventing contaminants from entering the engine, which can cause wear and reduce efficiency 11.

Male Union Elbow Connection

In plumbing and fluid systems, the retaining ring is often employed in male union elbows to ensure a tight and leak-free connection. This is particularly important in fuel and oil lines where any leakage can lead to significant issues, including fire hazards and system failures. The retaining ring helps maintain the seal integrity, ensuring that fluids are delivered efficiently and safely throughout the engine system 12.

General Plumbing Applications

Across various plumbing applications within the engine, the retaining ring is used to secure fittings and components. This includes connections in coolant systems, where maintaining a secure and leak-free joint is essential for efficient heat management and engine cooling. The retaining ring ensures that these connections remain intact under varying pressure and temperature conditions 13.

Conclusion

In summary, the part 3103225 retaining ring is a versatile component that enhances the functionality and reliability of engine systems by securing critical connections and assemblies. Its application across turbochargers, air filters, male union elbows, and general plumbing ensures that engine components operate efficiently and safely.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Simulation and Optimization of Internal Combustion Engines, Zhiyu Han, SAE International, 2022

↩ -

Understanding Automotive Electronics, William B. Ribbens, Elsevier Science, 2003

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Simulation and Optimization of Internal Combustion Engines, Zhiyu Han, SAE International, 2022

↩ -

Understanding Automotive Electronics, William B. Ribbens, Elsevier Science, 2003

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Simulation and Optimization of Internal Combustion Engines, Zhiyu Han, SAE International, 2022

↩ -

Owners Manual, QSK95 CM2350 K128M, Bulletin Number 5411389

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Simulation and Optimization of Internal Combustion Engines, Zhiyu Han, SAE International, 2022

↩ -

Understanding Automotive Electronics, William B. Ribbens, Elsevier Science, 2003

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.