This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

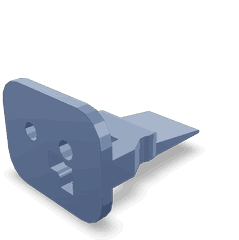

The 3163257 Connector Wiring Retainer by Cummins is a specialized component designed to enhance the reliability and integrity of electrical connections in heavy-duty truck systems. This part is integral to maintaining secure and dependable electrical connections, which are vital for the overall performance and safety of heavy-duty trucks.

Basic Concepts of Connector Wiring Retainers

A Connector Wiring Retainer is a device used in electrical systems to secure and maintain the integrity of wiring connections. Its primary function is to prevent wires from becoming dislodged or disconnected, which can lead to electrical failures. By ensuring that connections remain stable, these retainers contribute to the overall reliability and safety of the electrical system 1.

Purpose of the 3163257 Connector Wiring Retainer

The 3163257 Connector Wiring Retainer plays a role in the operation of a truck by securing wiring connections and ensuring electrical integrity. It is designed to hold wires in place, preventing them from moving or vibrating loose, which can disrupt electrical signals and cause system failures. This retainer is particularly important in heavy-duty trucks, where vibrations and harsh conditions can challenge the stability of electrical connections 2.

Key Features

The 3163257 Connector Wiring Retainer boasts several key features that enhance its performance. It is constructed from durable materials that can withstand the rigors of heavy-duty truck environments. The design includes elements that provide a secure grip on wires, ensuring they remain in place. Additionally, it is engineered to resist corrosion and environmental factors, further contributing to its reliability 3.

Benefits

The benefits of using the 3163257 Connector Wiring Retainer include improved reliability of electrical connections, resistance to vibration and environmental factors, and ease of installation and maintenance. By securing connections, it helps prevent electrical failures that can arise from loose or disconnected wires. Its durable construction ensures longevity, even in challenging conditions.

Installation Process

Proper installation of the 3163257 Connector Wiring Retainer involves several steps. Begin by identifying the correct location for the retainer within the truck’s electrical system. Use the appropriate tools to secure the retainer in place, ensuring it grips the wires firmly without causing damage. Follow best practices for electrical connections, such as ensuring all connections are clean and free from corrosion before installation.

Troubleshooting Common Issues

Common problems associated with Connector Wiring Retainers include loose connections or corrosion. To address these issues, inspect the retainer regularly for signs of wear or damage. If a connection appears loose, re-secure it using the appropriate tools. In cases of corrosion, clean the affected area thoroughly before re-installing the retainer. Regular maintenance can help prevent these issues from arising.

Maintenance Tips

To ensure the ongoing performance and longevity of the 3163257 Connector Wiring Retainer, regular maintenance is recommended. Inspect the retainer at regular intervals for signs of wear, corrosion, or loose connections. Clean the retainer and surrounding areas as needed to prevent buildup that could affect performance. Following these maintenance tips can help maintain the integrity of the electrical system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the heavy-duty truck industry, Cummins is known for its high-quality components and innovative solutions. The company’s commitment to excellence is reflected in its wide range of products, including the 3163257 Connector Wiring Retainer, designed to meet the demanding requirements of heavy-duty applications.

Role of Part 3163257 Connector Wiring Retainer in Engine Systems

The 3163257 Connector Wiring Retainer is an essential component in maintaining the integrity and functionality of the wiring harness repair kit within engine systems. This retainer ensures that the wiring harness remains securely in place, preventing any potential disconnections or damage to the wires during engine operation.

When integrated with the wiring harness repair kit, the 3163257 Connector Wiring Retainer plays a significant role in the following ways:

-

Secure Connection: It ensures that the repaired sections of the wiring harness are firmly held in place, reducing the risk of wire fatigue or accidental disconnections.

-

Vibration Resistance: Engines are subject to constant vibrations. The retainer helps mitigate the effects of these vibrations on the wiring harness, ensuring consistent electrical performance.

-

Protection from Environmental Factors: By keeping the wiring harness snugly in place, the retainer protects the wires from exposure to harsh environmental conditions, such as moisture, dirt, and extreme temperatures, which could otherwise lead to corrosion or insulation breakdown.

-

Facilitates Maintenance: The secure fit provided by the retainer makes it easier for mechanics to access and inspect the wiring harness during routine maintenance, ensuring that any potential issues can be identified and addressed promptly.

-

Enhances Safety: A well-retained wiring harness reduces the likelihood of electrical shorts or fires, contributing to the overall safety of the engine system.

Conclusion

In summary, the 3163257 Connector Wiring Retainer is a vital component that enhances the reliability and safety of the wiring harness repair kit within engine systems. Its role in securing connections, resisting vibrations, protecting against environmental factors, facilitating maintenance, and enhancing safety underscores its importance in ensuring the optimal performance of engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.