This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

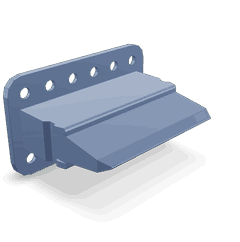

The Connector Wiring Retainer 3163989 is a component designed by Cummins to enhance the electrical system’s integrity in commercial trucks. This part ensures secure and efficient electrical connections, contributing to the overall reliability and safety of truck operations. Cummins, a renowned manufacturer in the industry, is known for its commitment to quality and innovation in producing truck components 1.

Basic Concepts of Connector Wiring Retainers

A Connector Wiring Retainer is a device used in electrical systems to secure and maintain the integrity of electrical connections. It plays a role in preventing disconnections and ensuring consistent electrical flow, which is vital for the reliable operation of a truck’s electrical system. By securing wires and connectors, it contributes to the safety and efficiency of truck operations 2.

Purpose of the 3163989 Connector Wiring Retainer

The 3163989 Connector Wiring Retainer is specifically designed to maintain secure and efficient electrical connections within a truck’s electrical system. It ensures that wires and connectors remain firmly in place, reducing the risk of disconnections that could lead to electrical faults or system failures. This part is integral to the electrical system’s stability and the truck’s overall performance 3.

Key Features

The 3163989 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and environmental factors. Its design includes elements that facilitate easy installation and secure fitting, while unique attributes such as corrosion resistance and flexibility under various conditions contribute to its reliability.

Benefits

The use of the 3163989 offers several benefits. It improves the stability of electrical connections, reducing the likelihood of faults that could disrupt truck operations. By ensuring secure connections, it enhances the overall reliability of the electrical system, contributing to safer and more efficient truck performance.

Installation Process

Installing the 3163989 involves several steps to ensure a secure fit. Begin by identifying the correct location for the retainer within the electrical system. Use the appropriate tools to attach the retainer to the wiring harness, ensuring all connections are tight and secure. Follow best practices for electrical work, including checking for proper alignment and tension to prevent future issues.

Troubleshooting Common Issues

Common problems associated with Connector Wiring Retainers include loose connections and wear and tear. To address these issues, first, inspect the retainer for signs of damage or corrosion. Tighten any loose connections and replace the retainer if it shows significant wear. Regular checks and maintenance can help prevent these issues from arising.

Maintenance Tips

To ensure the longevity and optimal performance of the 3163989, regular maintenance is recommended. Inspect the retainer at regular intervals for signs of wear, corrosion, or loose connections. Cleaning the retainer and its surrounding area can prevent buildup that might affect its performance. Following these maintenance practices will help maintain the electrical system’s integrity.

Cummins: Manufacturer Overview

Cummins is a leading manufacturer in the truck components industry, with a history of innovation and quality. The company is renowned for its commitment to producing reliable and efficient parts that enhance the performance and safety of commercial trucks. Cummins’ reputation is built on its dedication to excellence and continuous improvement in manufacturing processes.

Role of Part 3163989 Connector Wiring Retainer in Engine Systems

The 3163989 is an essential component in maintaining the integrity and functionality of the wiring harness repair kit within engine systems. This retainer plays a significant role in securing and organizing the electrical connections, ensuring that the wiring harness operates efficiently and reliably.

Integration with Wiring Harness Repair Kit

When integrating the Connector Wiring Retainer with a wiring harness repair kit, it is important to understand its function in preserving the structural and electrical integrity of the system. The retainer is designed to hold the wiring harness in place, preventing it from shifting or becoming dislodged during engine operation. This stability is vital for maintaining consistent electrical connections, which are necessary for the proper functioning of various engine components.

Ensuring Secure Connections

The Connector Wiring Retainer helps in ensuring that all electrical connections within the wiring harness are secure. By holding the wires in place, it reduces the risk of loose connections that could lead to intermittent electrical issues. This is particularly important in high-vibration environments typical of engine compartments, where unsecured wiring can lead to frayed wires or disconnected plugs.

Facilitating Maintenance and Repairs

In the context of a wiring harness repair kit, the Connector Wiring Retainer simplifies maintenance and repair processes. By keeping the wiring organized and secure, it allows mechanics to easily access and diagnose issues within the harness. This organization also aids in the replacement or repair of individual wires or connectors, reducing the time and complexity involved in such tasks.

Enhancing Durability and Reliability

The use of the Connector Wiring Retainer enhances the overall durability and reliability of the wiring harness. By protecting the wires from physical damage and ensuring they remain in their intended positions, it contributes to the longevity of the electrical system. This is especially beneficial in demanding applications where the engine system is subjected to harsh conditions.

Supporting System Performance

Ultimately, the Connector Wiring Retainer supports the performance of the entire engine system by maintaining the integrity of the electrical connections. Proper wiring ensures that all engine components receive the necessary power and signals to operate correctly, which is essential for optimal engine performance and efficiency.

Conclusion

The 3163989 Connector Wiring Retainer is a critical component in the electrical systems of commercial trucks, ensuring secure and reliable connections that contribute to the overall performance and safety of the vehicle. Its integration with wiring harness repair kits enhances the durability, reliability, and maintainability of the electrical system, supporting optimal engine performance.

-

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.