This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

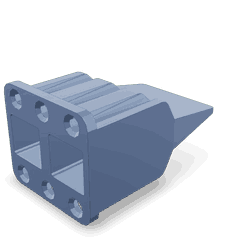

The 3164774 Connector Wiring Retainer by Cummins is a component designed to secure wiring harnesses within the electrical systems of heavy-duty trucks. Its role is significant in ensuring the integrity and reliability of electrical connections, which are vital for the proper operation of a truck’s various systems.

Basic Concepts of Connector Wiring Retainers

A Connector Wiring Retainer is a device used to hold wiring harnesses in place within a vehicle’s electrical system. It functions by securing the wiring, preventing it from moving or becoming dislodged, which could lead to electrical issues. This component contributes to maintaining secure and reliable electrical connections by ensuring that wires remain in their designated positions and are protected from physical damage or environmental factors 1.

Purpose of the 3164774 Connector Wiring Retainer

This Cummins part plays a role in the operation of a truck by securing wiring harnesses. This helps in preventing electrical issues that could arise from loose or damaged wires. By maintaining the integrity of the electrical connections, it supports the reliable operation of the truck’s electrical systems.

Key Features

The 3164774 Connector Wiring Retainer is characterized by its robust design and the materials used in its construction, which contribute to its performance and durability. It is engineered to withstand the harsh conditions typically encountered in heavy-duty truck operations, ensuring long-lasting reliability. Unique characteristics may include specific design elements that enhance its ability to secure wiring effectively 2.

Benefits

The use of the 3164774 Connector Wiring Retainer offers several benefits, including improved electrical reliability by ensuring secure connections, reduced risk of short circuits due to its ability to keep wiring in place, and enhanced durability in harsh operating conditions, thanks to its robust construction 3.

Installation Process

Proper installation of this part involves several steps to ensure a secure fit. This process may require specific tools or equipment, and following best practices is important to achieve the desired outcome. Detailed instructions should be provided by the manufacturer to guide through the installation process effectively.

Troubleshooting Common Issues

Common issues with Connector Wiring Retainers, such as loose connections or damage, can be identified through regular inspections. Troubleshooting steps may include checking for signs of wear or damage, ensuring all connections are secure, and replacing the retainer if necessary. Solutions should be approached methodically to address the specific issue at hand.

Maintenance Tips

To ensure optimal performance of the 3164774 Connector Wiring Retainer, regular maintenance is recommended. This includes conducting regular inspections to check for any signs of wear or damage, cleaning the retainer and surrounding areas to prevent buildup that could affect performance, and following replacement guidelines provided by the manufacturer.

Cummins Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industries, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to excellence, Cummins continues to be a leading provider of diesel engines, related technologies, and customer solutions worldwide.

Role of Part 3164774 Connector Wiring Retainer in Engine Systems

The 3164774 Connector Wiring Retainer is an essential component in maintaining the integrity and functionality of the wiring harness repair kit within engine systems. This retainer ensures that the wiring harness remains securely in place, preventing any potential damage or disconnection that could arise from vibrations or movement during engine operation.

When integrated with the wiring harness repair kit, the Connector Wiring Retainer plays a significant role in:

-

Securing Connections: It holds the wiring harness firmly in position, ensuring that all electrical connections remain intact. This is particularly important in high-vibration environments typical of engine compartments.

-

Protecting Wires: By keeping the wiring harness stable, the retainer helps protect individual wires from abrasion and wear, which can lead to shorts or open circuits.

-

Facilitating Repairs: In the context of a wiring harness repair kit, the retainer allows for easier and more reliable repairs. It ensures that newly installed or repaired sections of the harness are held securely, reducing the likelihood of future issues.

-

Enhancing Durability: The secure fit provided by the Connector Wiring Retainer contributes to the overall durability of the wiring harness, ensuring long-term reliability in engine systems.

Conclusion

In summary, the 3164774 Connector Wiring Retainer is a key component in the effective functioning and maintenance of wiring harness systems within engine environments. Its role in securing, protecting, and facilitating repairs makes it an indispensable part of the wiring harness repair kit.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.