This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

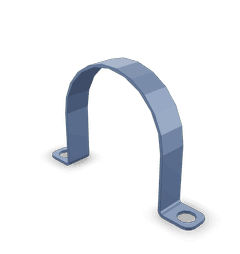

The 3171630 Retaining Clamp is a component manufactured by Cummins, a well-established name in the commercial truck industry. This retaining clamp is significant in the context of commercial truck maintenance and operation, providing a reliable means to secure various components within the truck’s systems.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold components in place within a system. They function by applying pressure to the components they are designed to secure, ensuring that these parts remain fixed and do not move or become dislodged during operation. In mechanical systems, retaining clamps play a role in maintaining the integrity and alignment of components, which is vital for the efficient and safe operation of the system 1.

Purpose of the 3171630 Retaining Clamp

The 3171630 Retaining Clamp is specifically designed to secure components within a truck’s system. It interacts with various systems or components, ensuring that they remain in the correct position and alignment. This is particularly important in systems where movement or misalignment could lead to decreased efficiency or potential damage.

Key Features

The 3171630 Retaining Clamp boasts several key features that enhance its functionality. It is composed of durable materials, ensuring longevity and resistance to wear and tear. The design elements of the clamp are tailored to provide a secure fit, minimizing the risk of component movement. Additionally, it may include unique characteristics such as adjustable settings or corrosion-resistant coatings, further enhancing its performance in various operating conditions.

Benefits

Utilizing the 3171630 Retaining Clamp offers several advantages. It contributes to improved reliability by securely holding components in place, which is crucial for the consistent operation of truck systems. The clamp’s durable construction ensures longevity, reducing the need for frequent replacements. Moreover, by maintaining component alignment and position, it plays a role in enhancing the overall efficiency of truck operations.

Installation Process

Installing the 3171630 Retaining Clamp requires careful attention to ensure proper functionality. The process involves positioning the clamp around the component it is designed to secure, followed by tightening it to the manufacturer’s specifications. This may require the use of specific tools to achieve the correct tension without overtightening, which could damage the component or the clamp itself.

Troubleshooting Common Issues

Common issues with retaining clamps may include improper tension, leading to either insufficient holding power or damage to the component. To address these issues, it is important to regularly inspect the clamp for signs of wear or misalignment. Adjustments can be made by loosening the clamp, repositioning it if necessary, and then retightening it to the correct specifications. In cases where the clamp is damaged or worn, replacement may be necessary to ensure optimal performance.

Maintenance Tips

To prolong the lifespan and effectiveness of the 3171630 Retaining Clamp, regular maintenance practices are recommended. This includes routine inspections to check for signs of wear, corrosion, or misalignment. Cleaning the clamp and its surrounding area can prevent the buildup of debris that may affect its performance. Additionally, following the manufacturer’s guidelines for tension and replacement can help maintain the clamp’s functionality over time.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its wide range of products that include engines, filtration systems, and aftermarket parts. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and efficient components that contribute to the performance and longevity of commercial trucks. Their product range is designed to meet the diverse needs of the industry, ensuring that truck operators have access to high-quality parts for maintenance and operation 2.

Cummins Engine Part 3171630: Retaining Clamp Application

The Cummins part number 3171630, a Retaining Clamp, is integral to the assembly and operation of several engine models. This part is designed to secure various components within the engine, ensuring they remain in place during operation.

Application in QSK60 Engines

The Retaining Clamp 3171630 is utilized in the QSK60 series engines, specifically in the QSK60 CM500 and QSK60 CM850 MCRS models. In these engines, the clamp plays a role in maintaining the integrity of the engine’s internal components.

- QSK60 CM500: This engine model benefits from the clamp’s ability to secure parts that are subject to high stress and vibration, ensuring longevity and reliability.

- QSK60 CM850 MCRS: Similarly, in the QSK60 CM850 MCRS, the retaining clamp is important for holding components in place, contributing to the engine’s overall performance and durability.

Functional Importance

The retaining clamp is a component in the engine’s assembly, providing the necessary support to prevent parts from shifting or coming loose. This is particularly important in high-performance engines like the QSK60 series, where precision and stability are paramount.

Installation Considerations

When installing the Retaining Clamp 3171630, it is important to follow the manufacturer’s guidelines to ensure proper fit and function. This includes using the correct torque specifications and ensuring that all mating surfaces are clean and free of debris. Proper installation is key to maintaining the engine’s performance and preventing potential failures.

Role of Part 3171630 Retaining Clamp in Engine Systems

The 3171630 Retaining Clamp is a component in securing and maintaining the integrity of various engine systems. Its application spans across multiple components, ensuring optimal performance and reliability.

Aftercooler

In the aftercooler system, the 3171630 Retaining Clamp is utilized to secure connections between the aftercooler core and the associated plumbing. This ensures that the compressed air is effectively cooled before entering the engine, enhancing efficiency and reducing the risk of thermal stress on engine components.

Turbocharger

Within the turbocharger arrangement, the 3171630 Retaining Clamp plays a role in maintaining the integrity of the exhaust and intake connections. By securely clamping these connections, it ensures that the turbocharger operates within its designed parameters, thereby optimizing boost pressure and overall engine performance.

Intercooler

For the intercooler, the 3171630 Retaining Clamp is employed to hold the intercooler core in place and to secure the connections to the intake and exhaust systems. This is vital for maintaining the efficiency of the intercooler in reducing the temperature of the compressed air, which directly impacts the engine’s power output and fuel efficiency.

Plumbing

In the engine’s plumbing system, the 3171630 Retaining Clamp is used to secure hoses and pipes that transport fluids such as coolant, oil, and fuel. This ensures that there are no leaks or disconnections, which could lead to system failures or reduced performance.

Thermostat Housing

The 3171630 Retaining Clamp is also integral in the thermostat housing assembly. It secures the housing to the engine block, ensuring a tight seal that prevents coolant leaks. This is important for maintaining the engine’s operating temperature within the optimal range, which is essential for engine longevity and performance.

Conclusion

The 3171630 Retaining Clamp by Cummins is a vital component in the maintenance and operation of commercial trucks. Its role in securing various engine components ensures the integrity, efficiency, and reliability of the truck’s systems. Proper installation, regular maintenance, and understanding its application across different engine models are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.