This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

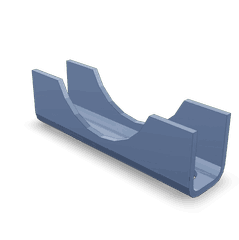

The Cummins 3284885 Retaining Clamp is a component designed to secure various parts within the mechanical systems of commercial trucks. Its role is significant in ensuring the stability and proper functioning of truck components, contributing to the overall efficiency and reliability of the vehicle.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold components in place. They operate by applying pressure to secure parts, preventing movement and ensuring that systems function as intended. In mechanical systems, retaining clamps are vital for maintaining the integrity and alignment of components, which is essential for the smooth operation of machinery 1.

Purpose of the Cummins 3284885 Retaining Clamp

The Cummins 3284885 Retaining Clamp serves a specific function in the operation of trucks by securing components within the engine and other mechanical systems. It interacts with various parts, ensuring they remain in the correct position and do not shift during operation, which could lead to malfunctions or decreased performance.

Key Features

The Cummins 3284885 Retaining Clamp is characterized by several key features that enhance its functionality. It is constructed from durable materials, designed to withstand the rigors of commercial truck operation. The clamp features a robust design that allows for secure fastening, and it includes elements that facilitate easy installation and removal when necessary.

Benefits

The advantages of using the Cummins 3284885 Retaining Clamp include improved reliability and durability in truck operations. By securely holding components in place, it contributes to the consistent performance of the truck’s mechanical systems. Additionally, its design enhances efficiency by ensuring that parts operate within the intended parameters, reducing the likelihood of wear or damage 2.

Installation Process

Installing the Cummins 3284885 Retaining Clamp requires following a series of steps to ensure proper fitting and function. The process involves preparing the area where the clamp will be installed, positioning the clamp over the component it is designed to secure, and then tightening it to the specified torque. Tools such as wrenches may be required to complete the installation.

Maintenance Tips

To ensure the longevity and consistent performance of the Cummins 3284885 Retaining Clamp, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage, and cleaning the clamp to remove any debris that could affect its operation. Following manufacturer guidelines for maintenance intervals will help maintain the clamp’s effectiveness 3.

Troubleshooting Common Issues

Common problems with the Cummins 3284885 Retaining Clamp may include loosening over time or damage from wear. Troubleshooting steps involve inspecting the clamp for signs of wear, ensuring it is properly tightened, and replacing it if necessary. Addressing issues promptly can prevent more significant problems with the truck’s mechanical systems.

Compatibility and Applications

The Cummins 3284885 Retaining Clamp is designed for use in specific models of commercial trucks. It is important to verify compatibility with the truck’s make and model to ensure proper function. Cummins provides information on the applications where this clamp is commonly used, aiding in selecting the correct component for the vehicle.

Safety Considerations

When working with the Cummins 3284885 Retaining Clamp, observing safety guidelines is crucial. This includes wearing appropriate personal protective equipment, ensuring the truck is turned off and cooled down before beginning work, and following all manufacturer instructions for handling, installation, and maintenance. Safety precautions help prevent accidents and ensure the clamp is installed and maintained correctly.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company has a history of innovation and commitment to providing solutions that meet the demands of the trucking industry, including components like the Cummins 3284885 Retaining Clamp.

Cummins Retaining Clamp Part 3284885 Compatibility

The Cummins Retaining Clamp part number 3284885 is designed to fit seamlessly with various engine models, ensuring secure and reliable performance. This part is integral to maintaining the integrity of engine components by providing a firm grip and preventing unwanted movement.

Engine Compatibility

-

6B5.9 Series

- The 3284885 retaining clamp is specifically engineered to fit within the 6B5.9 engine series. This engine is known for its robust design and is often utilized in heavy-duty applications, where reliability and durability are paramount.

-

Other Cummins Engines

- While the primary focus is on the 6B5.9 series, the 3284885 retaining clamp is also compatible with other Cummins engines. Its universal design allows it to be used across various engine models, ensuring that it meets the stringent requirements of different engine configurations.

Application and Installation

-

Precision Fit

- The retaining clamp is manufactured to precise specifications, ensuring a perfect fit and optimal performance. Its design allows for easy installation and removal, facilitating maintenance and repair processes.

-

Durability

- Constructed from high-quality materials, the 3284885 retaining clamp is built to withstand the rigors of continuous operation. This durability ensures that the clamp remains effective over the long term, contributing to the overall reliability of the engine.

-

Compatibility Across Models

- The versatility of the 3284885 retaining clamp extends beyond the 6B5.9 series. Its compatibility with other Cummins engines makes it a valuable component for technicians and engineers working with a range of engine types. This broad compatibility simplifies inventory management and ensures that the correct part is readily available for various applications.

Role of Part 3284885 Retaining Clamp in Engine Systems

The 3284885 Retaining Clamp is a critical component in securing and maintaining the integrity of various engine system assemblies. Its primary function is to ensure that components remain firmly in place, preventing any unwanted movement that could lead to inefficiencies or failures.

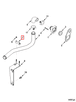

Housing Assembly

In the housing assembly, the 3284885 Retaining Clamp plays a significant role by securing the housing to the engine block. This ensures that the housing remains stable during engine operation, which is vital for the proper functioning of internal components. The clamp helps in distributing the load evenly, reducing stress on the housing and enhancing the durability of the assembly.

Thermostat Integration

When integrating the thermostat into the engine system, the 3284885 Retaining Clamp is used to hold the thermostat housing in position. This is important for maintaining the correct orientation and alignment of the thermostat, ensuring it can accurately regulate the engine’s temperature. Proper clamping prevents leaks and ensures that the thermostat operates within its designed parameters, contributing to overall engine efficiency.

Water Tube Bracket Securing

The water tube bracket, which is part of the cooling system, relies on the 3284885 Retaining Clamp to maintain its position. This bracket is responsible for guiding coolant flow to and from the engine, and any movement can disrupt this flow, leading to overheating or inadequate cooling. The clamp ensures that the bracket remains fixed, allowing for consistent and reliable coolant circulation.

Conclusion

The Cummins 3284885 Retaining Clamp is a fundamental component in maintaining the structural integrity and operational efficiency of various engine system assemblies. Its application in housing, thermostat, and water tube bracket setups underscores its importance in ensuring these components function as intended. Regular maintenance, proper installation, and adherence to safety guidelines are essential for maximizing the effectiveness of this part in commercial truck operations.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩ -

Fijalkowski, B. T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.