This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3533163 Retaining Ring is a specialized component designed for use in heavy-duty truck applications. Its purpose is to secure various parts within the engine system, ensuring they remain in place under operational conditions. This retaining ring is integral to maintaining the structural integrity and efficiency of the truck’s engine components.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They operate by fitting into a groove and exerting pressure against the walls of that groove, thereby securing the component in place. Retaining rings are widely used in various mechanical systems due to their simplicity, effectiveness, and ease of installation 1.

Purpose of the 3533163 Retaining Ring

The Cummins 3533163 Retaining Ring plays a specific role in the operation of heavy-duty trucks. It is designed to secure components within the engine, such as bearings or gears, ensuring they remain fixed during operation. This retaining ring is associated with critical systems within the truck, contributing to the overall reliability and performance of the engine 2.

Key Features

The Cummins 3533163 Retaining Ring is characterized by several key features that enhance its functionality. It is typically made from high-strength materials, ensuring durability under demanding conditions. The design of the ring includes precise dimensions and a robust construction, allowing it to withstand significant stress and vibration. Additionally, the ring may feature specific attributes tailored to its application, such as corrosion resistance or specialized coatings to improve performance 3.

Benefits

The use of the Cummins 3533163 Retaining Ring offers several advantages in truck operations. It contributes to improved reliability by securely holding components in place, reducing the risk of mechanical failure. The durability of the ring ensures long-term performance, even in harsh operating environments. Furthermore, the efficient design of the retaining ring supports the overall efficiency of the truck’s engine system, enhancing operational effectiveness 4.

Installation Process

Proper installation of the Cummins 3533163 Retaining Ring is crucial for its effectiveness. The process involves using appropriate tools, such as retaining ring pliers, to place the ring into the designated groove. Careful attention should be paid to ensure the ring is correctly seated and exerts uniform pressure against the groove walls. Following manufacturer guidelines and best practices during installation will help ensure the retaining ring functions as intended.

Common Issues and Troubleshooting

Typical problems that may arise with the Cummins 3533163 Retaining Ring include improper seating, damage during installation, or wear over time. Troubleshooting these issues involves inspecting the ring for correct placement and condition. If the ring is found to be damaged or incorrectly installed, it should be replaced or re-installed following the proper procedures to restore its function.

Maintenance Tips

Regular maintenance of the Cummins 3533163 Retaining Ring is important for ensuring its longevity and optimal performance. This includes periodic inspections to check for signs of wear or damage. Cleaning the ring and its groove to remove any debris or contaminants will help maintain its effectiveness. Adhering to recommended inspection intervals and care instructions will contribute to the overall reliability of the truck’s engine system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industry. The company is committed to quality and innovation, continually advancing its product offerings to meet the evolving needs of its customers.

Cummins Retaining Ring Part 3533163 Compatibility

The Cummins retaining ring part number 3533163 is a crucial component in various engine configurations. This part is designed to secure and stabilize different parts within the engine, ensuring optimal performance and longevity. Below is a detailed overview of the engines with which this retaining ring is compatible.

Compatible Engines

- 15N CM2380 M104B

- 4B3.9

- 6B5.9

- 6C8.3

- B5.9 G

- B5.9 GAS PLUS CM556

- B6.7 G CMOH6.0 B125

- B6.7S

- C GAS PLUS CM556

- C8.3 G

- G8.3

- GTA8.3 CM558

- ISB CM550

- ISB/ISD6.7 CM2150 SN

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B127

- ISB5.9G CM2180

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

- ISC CM554

- ISC CM850

- ISF3.8 CM2220 AN

- ISL CM554

- ISL G CM2180

Grouping of Compatible Engines

The retaining ring part 3533163 is versatile and fits into several engine families and configurations. Here is a grouping of the compatible engines based on their model series:

-

15N Series:

- 15N CM2380 M104B

-

4B Series:

- 4B3.9

-

6B Series:

- 6B5.9

-

6C Series:

- 6C8.3

-

B5.9 Series:

- B5.9 G

- B5.9 GAS PLUS CM556

-

B6.7 Series:

- B6.7 G CMOH6.0 B125

- B6.7S

-

C Series:

- C GAS PLUS CM556

- C8.3 G

-

G Series:

- G8.3

- GTA8.3 CM558

-

ISB Series:

- ISB CM550

- ISB/ISD6.7 CM2150 SN

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B127

- ISB5.9G CM2180

-

ISBE Series:

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

-

ISC Series:

- ISC CM554

- ISC CM850

-

ISF Series:

- ISF3.8 CM2220 AN

-

ISL Series:

- ISL CM554

- ISL G CM2180

This retaining ring is essential for maintaining the integrity of the engine components it secures, ensuring that parts remain in their designated positions and preventing wear and tear.

Role of Part 3533163 Retaining Ring in Engine Systems

The Part 3533163 Retaining Ring is an integral component in various engine systems, ensuring the secure positioning of parts and contributing to the overall efficiency and reliability of the engine.

In an Aftermarket Turbocharger, the retaining ring is used to hold the turbine wheel in place within the turbocharger housing, preventing any unwanted movement that could lead to imbalance or failure.

Within an Assembly Kit, it often secures components such as bearings or spacers, ensuring they remain in the correct position during operation.

For the Core Assembly and Core Assembly Heat Exchanger 40W, the retaining ring plays a role in maintaining the structural integrity of the assembly, particularly in securing fins or tubes that are critical for heat exchange efficiency.

In an Engine Installation Kit, it is commonly employed to secure sensors or other small components that need to be held firmly in place against vibrations.

The Exhaust Manifold Kit utilizes the retaining ring to secure gaskets or seals, ensuring a tight fit that prevents exhaust leaks.

For the Fuel Injection Pump and Fuel Pump Coupling, the retaining ring is essential in keeping components aligned and secure, which is vital for the precise operation of fuel delivery systems.

In Performance Parts, such as high-performance turbochargers or actuators, the retaining ring ensures that upgraded components are held securely, allowing for enhanced performance without the risk of part failure.

The Protective Cover for turbochargers may use retaining rings to secure the cover in place, protecting internal components from debris and damage.

In Turbocharger systems, whether stock or aftermarket, the retaining ring is used in various places such as securing the compressor wheel, ensuring the turbocharger actuator remains in place, and holding together turbocharger housing repair kits.

Overall, the Part 3533163 Retaining Ring is a small yet significant component across a wide range of engine systems, contributing to the secure assembly and reliable operation of complex engine components.

Conclusion

The Cummins 3533163 Retaining Ring is a critical component in heavy-duty truck engines, ensuring the secure positioning of various parts and contributing to the overall efficiency and reliability of the engine. Its robust design, compatibility with a wide range of engine configurations, and ease of installation make it an essential part for maintaining the structural integrity of engine components. Regular maintenance and proper installation are key to maximizing the performance and longevity of this retaining ring.

-

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Fischer, Robert, et al. The Automotive Transmission Book Powertrain. Springer, 2015.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Khajepour, Amir. Synthesis Lectures on Advances in Automotive Technology. Springer, 2023.

↩

SPECIFICATIONS

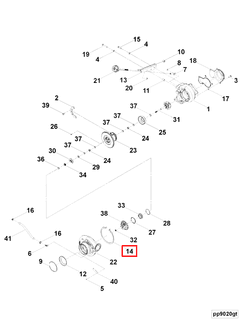

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Retaining Ring | 1 | 3527566 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.