This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

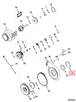

The Cummins 3537301 Retaining Ring is a specialized component designed for use in heavy-duty truck applications. Its purpose is to secure various parts within the truck’s mechanical systems, ensuring they remain in place under operational conditions. This retaining ring is significant due to its role in maintaining the integrity and functionality of critical truck components.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They operate by exerting a radial force that keeps parts securely in position. Typically made from spring steel, retaining rings come in various designs, including internal and external types, to accommodate different applications and load requirements 1.

Purpose of the 3537301 Retaining Ring

The Cummins 3537301 Retaining Ring is specifically designed to secure components within the truck’s engine and transmission systems. It plays a role in ensuring that parts such as gears, bearings, and shafts remain properly aligned and do not shift during operation. This helps maintain the efficiency and reliability of the truck’s mechanical systems.

Key Features

The Cummins 3537301 Retaining Ring is characterized by several key features that enhance its functionality. It is typically made from high-quality spring steel, providing the necessary strength and flexibility. The design includes a split configuration, allowing it to be easily installed and removed without the need for specialized tools. Additionally, the ring features a precise fit to ensure it securely holds components in place under various operational conditions.

Benefits

The use of the Cummins 3537301 Retaining Ring offers several advantages. It contributes to improved reliability by ensuring that critical components remain in their intended positions. This helps prevent wear and damage that could occur if parts were to shift or become misaligned. Additionally, the ring enhances the efficiency of the truck’s mechanical systems by maintaining proper alignment and reducing the risk of component failure. Its durable construction also contributes to the longevity of the associated truck components.

Installation Process

Installing the Cummins 3537301 Retaining Ring requires careful attention to ensure proper fitting. Begin by cleaning the area where the ring will be installed to remove any debris or contaminants. Use a retaining ring plier to expand the ring and place it around the shaft or within the housing. Ensure the ring is seated correctly and that it exerts an even radial force on the component it is securing. Double-check the installation to confirm that the ring is properly positioned and that the component is held securely in place.

Common Issues and Troubleshooting

Typical problems with retaining rings may include improper installation, which can lead to component misalignment or failure. To diagnose these issues, inspect the ring for signs of damage or deformation. Ensure that it is correctly seated and exerting the appropriate force on the component. If problems persist, consider replacing the retaining ring with a new one to ensure proper function 2.

Maintenance Tips

To ensure the longevity and proper function of the Cummins 3537301 Retaining Ring, perform routine checks during regular maintenance intervals. Inspect the ring for signs of wear, corrosion, or damage. Clean the area around the ring to prevent the accumulation of debris that could affect its performance. If any issues are detected, address them promptly to maintain the integrity of the truck’s mechanical systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the automotive and heavy-duty truck industry. The company offers a wide range of products designed to meet the demanding requirements of various applications, ensuring reliable performance and durability 3.

Compatibility

The Cummins part 3537301 Retaining Ring is designed to fit seamlessly with a variety of Cummins engines. This retaining ring ensures that certain parts within the engine remain securely in place, contributing to the overall reliability and performance of the engine. Below is a detailed overview of the engines with which this retaining ring is compatible.

Compatible Engines

-

QSK19 Series

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

-

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

-

QSK45 Series

- QSK45 CM500

-

QSK50 Series

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

-

QSK60 Series

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

-

QSK78 Series

- QSK78 CM500

-

QSK95 Series

- QSK95 CM2350 K111

-

QST30 Series

- QST30 CM2350 T101

- QST30 CM552

-

QSV Series

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

- QSW/QSV82

This retaining ring is engineered to fit snugly within the specified engine models, ensuring that it performs optimally under various operating conditions. Its design and material composition are tailored to withstand the rigors of engine operation, providing long-lasting durability and reliability.

Role in Engine Systems

The retaining ring, identified by part number 3537301, is a critical component in various engine systems, ensuring the secure assembly and operation of multiple parts. Its application spans across several critical engine components, contributing to the overall efficiency and reliability of the engine.

Aftercooler Core

In the aftercooler core, the retaining ring is used to secure the core elements in place, ensuring that the cooling process of the compressed air is efficient and consistent. This helps in maintaining optimal air temperature before it enters the engine, which is vital for performance and longevity.

Aftermarket Turbocharger

For aftermarket turbochargers, the retaining ring plays a significant role in securing the turbocharger’s internal components, such as the turbine and compressor wheels. This ensures that these parts remain in their correct positions under high-speed operation, contributing to the turbocharger’s efficiency and durability.

Assembly Turbocharger

In turbocharger assemblies, the retaining ring is utilized to hold various components in place, such as the bearing housing and the compressor housing. This secure fit is necessary to withstand the high rotational speeds and pressures within the turbocharger.

Camshaft and Gear

The retaining ring is also employed in the camshaft and gear assembly to secure the camshaft in place within the engine block. This ensures precise timing and operation of the valves, which is essential for the engine’s performance and fuel efficiency.

Compressor Housing

Within the compressor housing of a turbocharger, the retaining ring secures the compressor wheel and other internal components. This is crucial for maintaining the integrity of the compressor under high-pressure conditions, ensuring efficient air compression.

Connecting Rod and Piston

In the connecting rod and piston assembly, the retaining ring is used to secure the piston pin within the connecting rod. This ensures smooth and reliable operation of the piston within the cylinder, which is fundamental for engine performance.

Cylinder Head

The retaining ring is utilized in the cylinder head to secure various components, such as the valve springs and injectors. This ensures that these parts remain in their correct positions, contributing to the engine’s combustion efficiency and overall performance.

Gear Fuel Pump Kit

In the gear fuel pump kit, the retaining ring secures the gears within the pump housing. This is essential for maintaining the precise operation of the fuel pump, ensuring consistent fuel delivery to the engine.

Heat Exchanger and Water Cooler Turbocharger

For heat exchangers and water cooler turbochargers, the retaining ring is used to secure the components within the housing. This ensures efficient heat exchange and cooling, which is vital for maintaining optimal turbocharger performance.

Injectors

In fuel injectors, the retaining ring secures the injector nozzle within the housing. This is crucial for maintaining the precise fuel spray pattern, which is essential for efficient combustion and engine performance.

Integrated Fuel System Module Service/Repair Kit

Within the integrated fuel system module service/repair kit, the retaining ring is used to secure various components, ensuring the module’s integrity and performance during operation.

Kit, TA Luft Turbocharger

For TA Luft turbochargers, the retaining ring is utilized to secure internal components, ensuring compliance with environmental regulations and maintaining efficient turbocharger performance.

Performance Parts

In performance parts, the retaining ring is used to secure various components, ensuring that these parts can withstand the increased stresses and demands of high-performance applications.

Turbocharger

In general turbocharger applications, the retaining ring secures various internal components, ensuring the turbocharger’s reliability and efficiency under a wide range of operating conditions.

Turbocharger Aftermarket

For aftermarket turbochargers, the retaining ring is essential for securing components that have been modified or upgraded for enhanced performance, ensuring these parts can withstand the increased demands.

Turbocharger Assembly

In turbocharger assemblies, the retaining ring is used to secure various components, ensuring the assembly’s integrity and performance during operation.

Turbocharger Gasket Kit

Within the turbocharger gasket kit, the retaining ring may be used to secure gaskets in place, ensuring a proper seal and preventing leaks within the turbocharger.

Turbocharger Heat Exchanger

For turbocharger heat exchangers, the retaining ring secures components within the housing, ensuring efficient heat exchange and maintaining optimal turbocharger performance.

Turbocharger Kit

In turbocharger kits, the retaining ring is utilized to secure various components, ensuring the kit’s integrity and performance during installation and operation.

Conclusion

The Cummins 3537301 Retaining Ring is a vital component in heavy-duty truck applications, ensuring the secure assembly and operation of multiple engine parts. Its compatibility with various Cummins engines and its role in maintaining the efficiency and reliability of engine systems make it an indispensable part in the automotive industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.