3642028

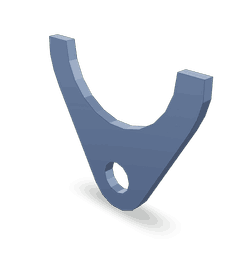

Retaining Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3642028 Retaining Clamp, manufactured by Cummins, is a critical component for commercial trucks. Retaining clamps are essential for the secure attachment of various parts and systems in heavy-duty vehicles, ensuring operational integrity and safety 1.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices designed to hold components in place by applying pressure. They are typically made from durable materials like steel or aluminum, chosen for their strength and resistance to wear 2. The material selection is vital as it impacts the clamp’s performance and longevity in demanding environments.

Purpose of the 3642028 Retaining Clamp

The 3642028 Retaining Clamp is engineered to secure components within the commercial truck’s system. It ensures parts remain firmly in place, contributing to the vehicle’s functionality and safety. By maintaining proper alignment and connection, this clamp helps prevent operational issues and potential safety hazards 3.

Key Features

The 3642028 features a robust design, constructed from high-quality materials to withstand heavy-duty use. Its design includes precision-engineered elements for a secure fit and reliable performance. Additionally, the clamp may have unique attributes such as corrosion-resistant coatings or enhanced gripping mechanisms 4.

Benefits

Using the 3642028 offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The clamp’s design facilitates ease of installation, minimizing downtime during maintenance. Furthermore, its enhanced performance in heavy-duty applications contributes to the overall efficiency and safety of the vehicle 5.

Installation Process

Installing the 3642028 requires following a precise procedure to ensure proper fit and function. The process involves securing the clamp around the designated components, using the appropriate tools to tighten it to the manufacturer’s specifications. Attention to detail during installation is crucial to avoid issues such as improper alignment or insufficient pressure 6.

Troubleshooting Common Issues

Common problems with retaining clamps include loosening over time or damage due to wear and tear. Troubleshooting steps may involve inspecting the clamp for signs of wear, ensuring it is properly tightened, or replacing damaged components. Knowing when to repair versus replace the clamp is important for maintaining vehicle safety and performance 7.

Maintenance Tips

Regular maintenance of the 3642028 is vital for its longevity and reliability. This includes periodic inspections for signs of wear or damage, ensuring it remains securely fastened, and cleaning any debris that may accumulate. Following a maintenance schedule helps prevent unexpected failures and ensures the clamp continues to perform effectively 8.

Safety Considerations

When working with retaining clamps, adhering to safety protocols is paramount. This includes wearing personal protective equipment (PPE) such as gloves and safety glasses to protect against injuries. Safe handling practices, such as using the correct tools and following manufacturer guidelines, are also crucial to ensure the clamp is installed and maintained safely 9.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a reputation for excellence. The company’s dedication to producing reliable and high-performance components is evident in its retaining clamps, including the 3642028 model 10.

Cummins Retaining Clamp 3642028 Compatibility

The Cummins Retaining Clamp part number 3642028 is designed to fit a variety of Cummins engines, ensuring secure and reliable performance. Here is a detailed breakdown of its compatibility with the listed engines:

K50 Series

- K50: This engine model is compatible with the retaining clamp, ensuring proper assembly and function.

KTA38GC CM558

- KTA38GC CM558: The retaining clamp is engineered to fit this model, providing necessary support and stability.

QSK38 Series

- QSK38 CM2150 MCRS: This engine model is compatible with the retaining clamp, ensuring secure assembly.

- QSK38 CM850 MCRS: The retaining clamp fits this engine model, providing the necessary retention.

QSK50 Series

- QSK50 CM2150 K107: The retaining clamp is compatible with this engine model.

- QSK50 CM2150 MCRS: This engine model is designed to work with the retaining clamp.

- QSK50 CM2350 K108: The retaining clamp fits this engine model, ensuring proper retention.

QSK60 Series

- QSK60 CM500: The retaining clamp is compatible with this engine model.

- QSK60 CM850 MCRS: This engine model is designed to work with the retaining clamp.

QSK95 Series

- QSK95 CM2350 K111: The retaining clamp fits this engine model.

- QSK95 CM2350 K113: This engine model is compatible with the retaining clamp.

The retaining clamp 3642028 is meticulously designed to ensure it fits seamlessly with the specified engine models, providing the necessary retention and stability required for optimal engine performance 11.

Role of Part 3642028 Retaining Clamp in Engine Systems

The 3642028 is instrumental in ensuring the secure and efficient operation of various engine components. It is particularly significant in the context of the auxiliary cooling system, where it helps maintain the integrity of connections and plumbing.

In the auxiliary cooling system, the Retaining Clamp is used to secure the plumbing associated with the aftercooler and intercooler water systems. This includes both the left bank and right bank aftercooler plumbing, ensuring that there are no leaks or disconnections that could compromise the cooling efficiency of the engine.

For the camshaft and gear system, the Retaining Clamp plays a role in keeping the components aligned and securely in place. This is essential for the smooth operation of the camshaft, which is responsible for opening and closing the engine’s valves in sync with the pistons.

In the engine oil system, the Retaining Clamp is employed to secure connections within the plumbing, ensuring that oil flows consistently and without interruption to lubricate moving parts. This is vital for reducing friction and wear on engine components.

The injectors also benefit from the secure connections provided by the Retaining Clamp. By ensuring that the fuel lines are firmly in place, it helps maintain the precise delivery of fuel to the combustion chambers, which is essential for engine performance.

Overall, the 3642028 is a key component in maintaining the reliability and performance of various engine systems by ensuring that all connections are secure and leak-free 12.

Conclusion

The 3642028 Retaining Clamp by Cummins is a vital component in the operation of commercial trucks. Its robust design, durable construction, and precise engineering ensure secure and reliable performance across various engine systems. Regular maintenance and adherence to safety protocols are essential for maximizing the clamp’s effectiveness and longevity.

-

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Asef, Pedram, et al. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Asef, Pedram, et al. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Asef, Pedram, et al. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.