This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

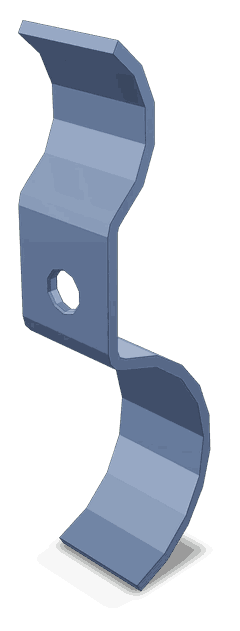

The 3646729 Retaining Clamp, manufactured by Cummins, is a vital component in the commercial truck industry. This part is specifically designed for use in commercial trucks, where it secures various parts and assemblies, ensuring they remain in place under demanding conditions. Retaining clamps are essential for the operation of heavy-duty trucks, contributing to the vehicle’s overall functionality and safety.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold parts together or in place by applying pressure to the components they secure. This helps prevent movement and ensures stability. These clamps are typically made from materials like steel, aluminum, or polymers, chosen for their strength, durability, and resistance to environmental factors. The material used can significantly influence the clamp’s performance and longevity 1.

Purpose of the 3646729 Retaining Clamp

The 3646729 Retaining Clamp is designed to secure components within a truck’s engine and other mechanical systems. By keeping parts in their intended positions, this clamp helps maintain the integrity of the truck’s operations, ensuring that all systems work together efficiently. Its role is crucial in contributing to the vehicle’s overall functionality and safety 2.

Key Features

The 3646729 Retaining Clamp features several elements that enhance its effectiveness and durability. Constructed from high-quality materials, it offers superior resistance to wear and environmental factors. Its unique characteristics, such as a specific shape or attachment mechanism, distinguish it from other clamps, making it particularly suited for its intended applications.

Benefits

Using the 3646729 Retaining Clamp in truck maintenance and operation offers several advantages. Its durability ensures long-term performance, reducing the need for frequent replacements. The clamp’s design facilitates ease of installation, allowing for quick and efficient setup. Furthermore, its performance under various conditions, including extreme temperatures and vibrations, makes it a reliable choice for commercial truck applications 3.

Installation Process

Installing the 3646729 Retaining Clamp requires following a step-by-step process to ensure proper setup. Begin by identifying the correct location for the clamp within the truck’s system. Use the appropriate tools to secure the clamp in place, ensuring it applies the necessary pressure to the components it is designed to hold. Adhering to best practices during installation will help maximize the clamp’s effectiveness and longevity.

Troubleshooting Common Issues

Common problems associated with retaining clamps include wear, malfunction, or improper installation. Recognizing signs of these issues, such as unusual noises or component movement, is important for maintaining the truck’s performance. Practical solutions may involve inspecting the clamp for damage, ensuring it is correctly installed, or replacing it if necessary. Regular checks can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance of the 3646729 Retaining Clamp is key to ensuring its longevity and optimal performance. This includes inspecting the clamp for signs of wear or damage, cleaning it to remove any debris or contaminants, and ensuring it remains securely in place. Following an inspection schedule and adhering to recommended cleaning procedures will help maintain the clamp’s effectiveness and contribute to the overall reliability of the truck.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality products. With a history of innovation and commitment to quality, Cummins has established a strong reputation for producing reliable and efficient automotive components. The company’s dedication to excellence is evident in its product offerings, including the 3646729 Retaining Clamp, which exemplifies Cummins’ focus on quality and performance in the commercial truck sector.

Cummins Retaining Clamp Part 3646729 in Engine Applications

The Cummins Retaining Clamp part number 3646729 is a critical component in the assembly and maintenance of various engine systems. This part is designed to securely hold and stabilize different engine parts, ensuring optimal performance and longevity of the engine.

In the K50 engine series, the retaining clamp is integral to maintaining the integrity of the engine’s internal components. It is often used to secure hoses, brackets, and other parts that need to be firmly attached to prevent movement or detachment during operation. The precision engineering of the Cummins retaining clamp ensures that it can withstand the high pressures and temperatures typical of engine environments.

For the K50 engines, the retaining clamp is particularly important in areas where vibration and stress are common. Its robust design provides a reliable method of attachment, reducing the risk of leaks and mechanical failures. This clamp is also used in conjunction with other Cummins parts, creating a cohesive and dependable system that supports the engine’s overall functionality.

In the broader context of Cummins engine applications, the retaining clamp part 3646729 is a versatile component. It is used across various engine models and configurations, highlighting its universal applicability and importance in engine assembly. The clamp’s design allows it to be customized for different parts and applications, making it a staple in the maintenance and repair of Cummins engines.

Role of Part 3646729 Retaining Clamp in Engine Systems

The Part 3646729 Retaining Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the alignment and stability of components, thereby contributing to the overall performance and reliability of the engine.

Camshaft and Gear Assembly

In the camshaft and gear assembly, the Retaining Clamp plays a significant role in keeping the camshaft securely in place. This ensures that the camshaft operates smoothly and maintains proper timing with the engine’s crankshaft. The stability provided by the clamp prevents undue wear and tear on the camshaft bearings and gears, which can lead to improved engine performance and longevity.

Fuel Injectors

For fuel injectors, the Retaining Clamp is used to secure the injectors in their designated positions within the engine block or cylinder head. This ensures that the injectors deliver fuel precisely and consistently, which is vital for optimal combustion and engine efficiency. The clamp helps in maintaining the injectors’ alignment, reducing the risk of fuel leaks and ensuring that the fuel delivery system operates within specified parameters.

Aftercooler Plumbing

In the context of the right bank aftercooler plumbing, the Retaining Clamp is employed to secure the various hoses and fittings that make up the aftercooling system. This system is responsible for cooling the compressed air from the turbocharger before it enters the engine’s combustion chambers. By keeping the plumbing components firmly in place, the clamp ensures that the aftercooler operates efficiently, contributing to better engine performance and reduced thermal stress on engine components.

General Engine Parts

Across various engine parts, the Retaining Clamp is utilized to secure components that require precise positioning and stability. Whether it’s securing sensors, gaskets, or other miscellaneous parts, the clamp ensures that these components remain in their correct locations, thereby maintaining the integrity and performance of the engine system.

Performance Implications

The consistent and reliable operation of the Retaining Clamp directly influences the engine’s performance. By ensuring that all components are securely held in place, the clamp contributes to smoother engine operation, reduced vibration, and enhanced overall efficiency. This, in turn, leads to better fuel economy, lower emissions, and increased engine lifespan.

Conclusion

The 3646729 Retaining Clamp is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its role in securing various parts and assemblies ensures the vehicle’s overall functionality and safety. The clamp’s durability, ease of installation, and performance under various conditions make it a reliable choice for commercial truck applications. Regular maintenance and proper installation are key to maximizing its effectiveness and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.