3648724

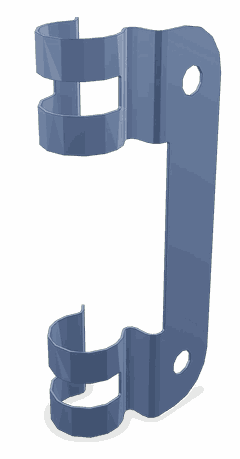

Wire Retaining Clip

Cummins®

IN STOCK

10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3648724 Wire Retaining Clip, manufactured by Cummins, is a component designed to secure wires and cables within heavy-duty truck systems. Cummins, a well-established name in the industry, produces this clip to ensure the reliable operation of electrical systems in demanding environments.

Basic Concepts of Wire Retaining Clips

Wire retaining clips are small yet vital components used across automotive and industrial applications. Their primary function is to hold wires and cables in place, preventing them from moving or vibrating, which could lead to damage or disconnection. These clips are typically made from durable materials to withstand various environmental conditions and mechanical stresses 1.

Purpose of the 3648724 Wire Retaining Clip in Truck Operations

The 3648724 Wire Retaining Clip plays a specific role in the operation of heavy-duty trucks by securing wires and cables within the vehicle’s electrical system. This ensures that the wires remain in their designated positions, reducing the risk of electrical faults due to wire displacement or damage. Maintaining the integrity of the electrical system is important for the reliable performance of the truck 2.

Key Features

The 3648724 Wire Retaining Clip is characterized by several key features that enhance its functionality. It is constructed from high-quality materials, ensuring durability and resistance to environmental factors. The design of the clip allows for easy installation and removal, facilitating maintenance and repairs. Additionally, the clip’s unique characteristics, such as its shape and size, are tailored to fit specific wire diameters and applications, providing a secure hold without damaging the wires 3.

Benefits of Using the 3648724 Wire Retaining Clip

Utilizing the 3648724 Wire Retaining Clip offers several advantages. It improves wire management within the truck, ensuring that wires are organized and secured, which can simplify troubleshooting and maintenance tasks. The clip’s durable construction enhances the reliability of the electrical system, even in harsh operating conditions. Furthermore, its design contributes to the overall safety and efficiency of the truck’s electrical system by preventing wire damage and ensuring consistent electrical connections 4.

Installation Guidelines

To install the 3648724 Wire Retaining Clip, first, identify the location where the wire needs to be secured. Use the appropriate tool to gently place the clip over the wire, ensuring it is positioned correctly. Apply firm pressure to snap the clip into place, securing the wire without over-tightening, which could damage the wire insulation. Verify the clip is securely attached and the wire is held firmly in place.

Troubleshooting Common Issues

Common issues with wire retaining clips include loose connections or damage to the clip or wire. To address these problems, inspect the clip and wire for signs of wear or damage. If the clip is loose, try repositioning it or replacing it if necessary. For damaged wires, assess the extent of the damage and repair or replace the wire as needed. Regular inspections can help identify and resolve issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance of the 3648724 Wire Retaining Clip involves periodic inspections to ensure it remains securely attached and in good condition. Clean the clip and surrounding area to remove any dirt or debris that could affect its performance. If the clip shows signs of wear or if the wire insulation is compromised, consider replacing the clip to maintain the integrity of the electrical system.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the heavy-duty truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the 3648724 Wire Retaining Clip, which is designed to meet the demanding requirements of heavy-duty applications 5.

Compatibility with Cummins Engines

The Wire Retaining Clip 3648724 is designed to fit seamlessly with the following Cummins engine series:

- QSK19 CM2350 K114

- QSK50 CM2350 K108

- QST30 CM2350 T101

These engines share a commonality in their requirement for efficient and reliable electrical management. The Wire Retaining Clip 3648724 ensures that wires are properly managed and secured, thereby preventing potential damage and enhancing overall engine performance.

Role of the 3648724 Wire Retaining Clip in Engine Systems

The 3648724 Wire Retaining Clip is an essential component in the secure and efficient operation of various engine systems. It is primarily responsible for maintaining the integrity and organization of wiring within the engine compartment.

Integration with Nitrogen Oxide Sensor

In systems equipped with a Nitrogen Oxide Sensor, the Wire Retaining Clip ensures that the sensor’s wiring is neatly organized and protected from potential damage. This is particularly important as the sensor plays a key role in monitoring emissions and ensuring the engine operates within environmental regulations.

Application in Module and Engine Control Systems

When dealing with Module and Engine Control systems, the Wire Retaining Clip is utilized to secure wiring that connects these modules to the engine control unit. This helps in reducing electrical noise and ensuring consistent signal transmission, which is vital for the accurate functioning of the engine control system.

Use with Module Bracket and Retaining Brace Bracket

In configurations where a Module Bracket or Retaining Brace Bracket is present, the Wire Retaining Clip is employed to keep wiring away from moving parts and high-temperature areas. This not only protects the wiring but also enhances the overall safety and reliability of the engine system.

Functionality in Turbocharger Oil and Water Tube Bracket Systems

For engines with Turbocharger Oil and Water Tube Brackets, the Wire Retaining Clip is crucial in managing the wiring that interfaces with these components. It ensures that the wiring does not interfere with the operation of the turbocharger or the flow of oil and water, thereby maintaining optimal engine performance.

Role in Plumbing and Wiring Retainer Bracket

In systems where Plumbing and a Wiring Retainer Bracket are used, the Wire Retaining Clip aids in the organization and protection of wiring that runs alongside plumbing lines. This is important for preventing electrical issues and ensuring that both the electrical and fluid systems operate efficiently.

General Application Across Engine Systems

Across various engine systems, the 3648724 Wire Retaining Clip is a fundamental component in maintaining the structural integrity and operational efficiency of wiring. Its application is widespread, touching upon numerous aspects of engine design and function, from sensor integration to module connectivity and beyond.

Conclusion

The 3648724 Wire Retaining Clip is a critical component in the maintenance and operation of heavy-duty truck electrical systems. Its design and functionality ensure that wires and cables are securely held in place, reducing the risk of electrical faults and enhancing the overall reliability of the truck’s electrical system. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Cummins Inc. (n.d.). L9 CM2670 L135C, Service Manual (5579957).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.