3686883

Retaining Ring

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Retaining Rings

Retaining rings, also known as circlips or snap rings, are indispensable mechanical components used to secure parts in place. These rings are vital in various applications where preventing axial or radial movement of components is necessary. Typically made from materials like stainless steel or carbon steel, retaining rings are chosen for their durability and resistance to wear, ensuring they can withstand the demanding conditions of commercial truck engines 1.

How Retaining Rings Work

Retaining rings operate by creating a clamping force between two or more parts. They are installed in a groove on either a shaft or a housing. There are two primary types of retaining rings: internal and external. Internal retaining rings fit into a groove on the outside of a shaft, while external retaining rings fit into a groove on the inside of a housing. Upon installation, the ring deforms slightly, generating a clamping force that securely holds the parts together, preventing any unwanted movement 2.

Purpose of the Cummins 3686883 Retaining Ring

The Cummins 3686883 retaining ring is a critical component in the operation of commercial truck engines. It is specifically designed to secure various engine components, ensuring they remain in place under the high stress and vibrations typical of heavy-duty applications. This retaining ring is essential for maintaining the integrity and efficiency of the engine, as it prevents parts from shifting or coming loose, which could lead to performance issues or engine failure.

Role in Truck Operations

In the context of truck engines, the 3686883 retaining ring ensures that components such as gears, bearings, and pulleys remain securely in place. This security is vital for the smooth operation of the engine. Any movement or misalignment of these components can result in significant performance issues or even engine failure. By providing a reliable means of securing these parts, the retaining ring contributes to the overall reliability and longevity of the truck’s engine 3.

Troubleshooting and Maintenance

Proper maintenance of retaining rings is essential to ensure they continue to perform their function effectively. Here are some tips for troubleshooting and maintaining the Cummins 3686883 retaining ring:

-

Regular Inspection: Periodically inspect the retaining ring for signs of wear, deformation, or damage. If the ring appears damaged, it should be replaced to prevent potential failure.

-

Proper Installation: Ensure that the retaining ring is correctly installed in its designated groove. Incorrect installation can lead to improper clamping force and eventual failure.

-

Lubrication: Although retaining rings are designed to operate without lubrication, ensuring that the surrounding components are well-lubricated can help reduce wear and extend the life of the ring.

-

Replacement: If the retaining ring shows signs of wear or has failed, it should be replaced promptly. Using a retaining ring that is the correct size and type for the application is crucial.

Cummins: A Leader in Engine Manufacturing

Cummins is a globally recognized leader in the manufacturing of engines and related components for commercial trucks and heavy-duty vehicles. With a reputation for producing high-quality, reliable parts, Cummins has established itself as a trusted name in the industry. The company’s commitment to innovation and quality ensures that its parts, including the 3686883 retaining ring, meet the rigorous demands of commercial truck operations.

Expertise and Authority

As an expert in commercial truck parts, it is essential to understand the critical role that components like the Cummins 3686883 retaining ring play in the overall performance and reliability of truck engines. By providing detailed information about the function, importance, and maintenance of retaining rings, this article aims to educate engineers, mechanics, truck drivers, and fleet operators on the significance of these components in ensuring the smooth operation of their vehicles.

Role of Part 3686883 Retaining Ring in Engine Systems

The retaining ring, identified by part number 3686883, is an essential component in the assembly and maintenance of various engine systems. Its primary function is to secure and hold components in place, ensuring the integrity and performance of the engine.

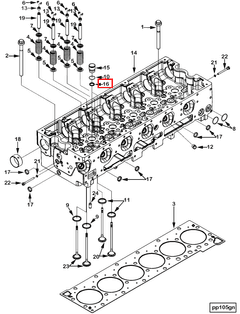

Cylinder Head Assembly

In the cylinder head assembly, the retaining ring plays a significant role in securing components such as valve springs and keepers. By holding these parts in place, it ensures that the valves operate correctly within their designated paths, contributing to efficient combustion and overall engine performance. The precise fit provided by the retaining ring is vital for maintaining the alignment and function of the valve train.

Overhaul Kit Integration

When an engine undergoes an overhaul, the retaining ring is often included in overhaul kits to replace worn or damaged rings. This ensures that all components are securely held in place during the rebuild process. The retaining ring’s role in an overhaul kit is to provide a reliable and consistent method for securing new or refurbished parts, which is essential for the engine’s longevity and performance post-overhaul.

Performance Parts Enhancement

In performance engine builds, the retaining ring is used to secure high-performance components that are subjected to greater stresses and higher operating temperatures. For instance, in a performance camshaft setup, the retaining ring ensures that the cam followers or other cam-related components remain in place under extreme conditions. This not only enhances the engine’s performance but also contributes to its reliability under high-stress scenarios.

Conclusion

Overall, the Cummins 3686883 retaining ring is a fundamental component in ensuring the secure assembly and reliable operation of various engine systems, from standard maintenance to high-performance applications. Its role in securing critical components, maintaining engine integrity, and contributing to overall performance makes it an indispensable part in the world of commercial truck engines.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

S. A. Miedema, Z. Lu. The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema, 2010.

↩ -

QSZ13 CM2150 Z101. Operation and Maintenance Manual. Bulletin Number 4358365.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.