This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

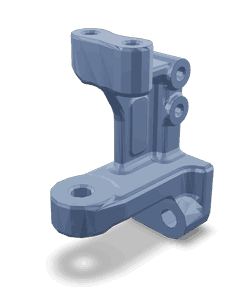

The Cummins 3687109 Retaining Brace is a critical component designed for heavy-duty truck applications. It plays a significant role in maintaining the stability and performance of the vehicle’s mechanical system. Understanding its purpose and significance is essential for appreciating its contribution to the integrity of truck components.

Basic Concepts of Retaining Braces

Retaining braces are mechanical components used to secure and stabilize parts within a system. They are vital for maintaining the alignment and structural integrity of various components, ensuring they function correctly under operational conditions. In heavy-duty trucks, retaining braces help withstand the stresses and vibrations encountered during operation, contributing to the longevity and reliability of the truck’s mechanical systems 1.

Purpose of the 3687109 Retaining Brace

The 3687109 Retaining Brace is designed to support and secure specific components within a truck’s engine or transmission system. Its function is to provide additional stability to these components, ensuring they remain in the correct position and operate efficiently. This contributes to the overall performance and reliability of the truck’s mechanical system 2.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and resistance to wear. Its design includes precise fitting mechanisms and robust construction, which enhance its performance. These features contribute to the brace’s ability to effectively secure components and withstand the demanding conditions of heavy-duty truck operation 3.

Benefits of Using the 3687109 Retaining Brace

Incorporating the Retaining Brace into a truck’s mechanical system offers several advantages. It contributes to improved durability by securing components against movement and wear. Enhanced safety is another benefit, as the brace helps prevent component failure that could lead to operational hazards. Additionally, the brace can increase efficiency in truck operations by ensuring components function as intended, reducing the likelihood of downtime due to mechanical issues 4.

Installation Process

Installing the 3687109 Retaining Brace requires careful attention to ensure it is correctly positioned and secured. The process involves identifying the correct location for the brace within the truck’s mechanical system, using the appropriate tools to install it, and verifying that it is properly fastened. Detailed instructions and any necessary tools should be consulted to ensure a successful installation.

Troubleshooting Common Issues

Common issues with the 3687109 Retaining Brace may include improper installation, wear and tear, or damage due to operational stress. Addressing these issues involves inspecting the brace for signs of damage or misalignment, ensuring it is correctly installed, and performing any necessary repairs or replacements. Regular maintenance can help prevent many of these issues, ensuring the brace continues to function effectively.

Maintenance Tips

Regular maintenance of the 3687109 Retaining Brace is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, ensuring it remains securely fastened, and addressing any issues promptly. Following manufacturer guidelines for maintenance can help maximize the effectiveness of the brace and contribute to the overall reliability of the truck’s mechanical system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the automotive industry, particularly in the heavy-duty truck sector, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a trusted name in the industry.

Role of Part 3687109 Retaining Brace in Engine Systems

The 3687109 Retaining Brace is an essential component that ensures the stability and proper functioning of various engine systems. It plays a significant role in maintaining the structural integrity and alignment of components within the engine arrangement.

Accessory Support

In the accessory support system, the Retaining Brace secures accessories such as the alternator, power steering pump, and air conditioning compressor. By providing a stable mounting point, it ensures these accessories remain firmly in place, reducing vibrations and potential wear. This stability is vital for the consistent operation of these accessories, which are integral to the engine’s overall performance.

Exhaust Recirculation Air System

Within the Exhaust Gas Recirculation (EGR) system, the Retaining Brace helps maintain the precise alignment of the EGR valve and associated piping. Proper alignment is necessary for the efficient recirculation of exhaust gases back into the intake manifold, which helps reduce nitrogen oxides (NOx) emissions. The brace ensures that the EGR system components are held in the correct position, allowing for optimal gas flow and emission control.

Recirculation System

In recirculation systems, such as those involving air intake or cooling systems, the Retaining Brace supports ducts and hoses. It ensures that these components remain securely attached and correctly positioned. This is important for maintaining the efficiency of air flow within the engine bay, which directly impacts engine performance and cooling effectiveness.

Conclusion

By integrating the 3687109 Retaining Brace into these systems, engineers and mechanics can ensure that engine components operate within their designed parameters, leading to improved reliability and performance. Regular maintenance and proper installation of this part are crucial for maximizing its benefits and ensuring the longevity of the truck’s mechanical system.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Sander, Frank. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Ribbens, William B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Minaker, Bruce P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.