This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

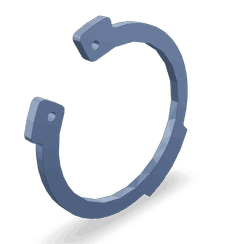

The 3709753 Retaining Ring, manufactured by Cummins, is a component used in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts designed to enhance the performance and reliability of truck engines. Retaining rings, in general, play a role in mechanical systems by securing components in place, ensuring they remain fixed during operation. This part is specifically designed to meet the demanding requirements of commercial truck applications.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners that secure components within a housing or on a shaft. They function by fitting into a groove and exerting a radial force that holds the component in place. This mechanism is important in preventing components from moving out of position due to vibrations or operational stresses. Retaining rings come in various designs, including internal and external types, each suited to different applications based on the specific requirements of the assembly 1.

Purpose of the 3709753 Retaining Ring in Truck Operations

In the context of commercial trucks, the 3709753 Retaining Ring secures specific components within the engine or transmission system. It plays a role in maintaining the integrity of the assembly by preventing parts from dislodging. This is particularly important in high-stress environments where vibrations and thermal expansions are common. By securing components, the retaining ring contributes to the smooth operation and longevity of the truck’s mechanical systems 2.

Key Features of the 3709753 Retaining Ring

The 3709753 Retaining Ring is designed with specific characteristics to perform effectively in its intended application. Its shape and size are tailored to fit precisely into the grooves of the components it secures. Made from high-strength materials, it offers durability and resistance to wear and corrosion. These material properties ensure that the retaining ring can withstand the operational stresses and environmental conditions encountered in commercial truck applications 3.

Benefits of Using the 3709753 Retaining Ring

The use of the 3709753 Retaining Ring provides several advantages. It enhances the reliability of the mechanical assembly by ensuring components remain securely in place. The design of the ring allows for easy installation and removal, facilitating maintenance procedures. Additionally, its robust construction contributes to the longevity of the assembly, reducing the need for frequent replacements.

Installation and Usage Guidelines

Proper installation of the 3709753 Retaining Ring is crucial for its effective function. The process involves using appropriate tools to place the ring into the designated groove without damaging it. Best practices include ensuring the groove is clean and free of debris before installation. Careful handling during installation helps maintain the integrity of the ring and the components it secures.

Troubleshooting Common Issues

Common issues with retaining rings include displacement or damage, which can lead to component failure. Diagnosis involves inspecting the ring and the groove for signs of wear or misalignment. Resolution may require replacing the retaining ring or addressing issues with the components it secures. Regular inspections can help identify potential problems before they lead to more significant issues.

Maintenance Tips

Regular inspection and maintenance of the 3709753 Retaining Ring are recommended to ensure ongoing performance. This includes checking for signs of wear, corrosion, or damage during routine maintenance checks. Cleaning the groove and the ring itself can prevent debris from affecting its function. Following manufacturer guidelines for maintenance can help extend the life of the retaining ring and the components it secures.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial applications 4.

Cummins Retaining Ring 3709753 Compatibility

The Cummins Retaining Ring part number 3709753 is designed to fit a variety of Cummins engines. This part is crucial for maintaining the integrity of the engine’s components by securing and retaining certain parts in place.

Compatible Engines

15N Series Engines:

- 15N CM2380 M104B

6C Series Engines:

- 6C8.3

ISG Series Engines:

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

ISM Series Engines:

- ISM CM570

ISX Series Engines:

- ISX CM870

L10 Series Engines:

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

L9 Series Engines:

- L9.3 L105

- L9.5 L117

M11 Series Engines:

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

QSG Series Engines:

- QSG12 CM2880 G112

QSM Series Engines:

- QSM11 CM570

X12N Series Engines:

- X12N CMMDG1 X143B

Grouping of Compatible Engines

15N Series: The 15N CM2380 M104B engine is part of the 15N series, known for its robust design and reliability in various applications.

6C Series: The 6C8.3 engine is a part of the 6C series, which is recognized for its efficiency and performance.

ISG Series: The ISG11 CM2880 G108, ISG12 CM2880 G107, and ISG12 G CMOH6.0 G111 engines are part of the ISG series, designed for industrial applications requiring high power output.

ISM Series: The ISM CM570 engine is part of the ISM series, which is known for its balance of power and fuel efficiency.

ISX Series: The ISX CM870 engine is part of the ISX series, which is highly regarded for its performance in heavy-duty applications.

L10 Series: The L10 CELECT, L10 GAS, and L10 MECHANICAL engines are part of the L10 series, offering a range of options for different fuel types and applications.

L9 Series: The L9.3 L105 and L9.5 L117 engines are part of the L9 series, designed for applications requiring lower power output.

M11 Series: The M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL engines are part of the M11 series, which provides a range of options for various industrial and commercial applications.

QSG Series: The QSG12 CM2880 G112 engine is part of the QSG series, designed for specific industrial needs.

QSM Series: The QSM11 CM570 engine is part of the QSM series, which is known for its reliability and efficiency.

X12N Series: The X12N CMMDG1 X143B engine is part of the X12N series, designed for specialized applications requiring high performance and durability.

Role of Part 3709753 Retaining Ring in Engine Systems

The part 3709753 retaining ring is a fundamental component across various engine systems, ensuring that all parts are securely held in place, thereby contributing to the reliability and efficiency of the engine.

Core and Housing Kit

In the core and housing kit, the retaining ring plays a significant role in securing the core components within the housing. This ensures that the core remains firmly in place, preventing any misalignment or movement that could affect the engine’s performance.

Core Assembly Variants

For the core assembly WH2D, H2C, H2S, and heat exchanger variants (40 and 50), the retaining ring is used to hold the core components in position. This is vital for maintaining the structural integrity and efficiency of the heat exchange process, which is fundamental for engine cooling and performance.

H2E Core Assembly and Emissions Rebuild Kit

In the H2E core assembly and the emissions rebuild kit, the retaining ring ensures that all components are correctly aligned and secured. This is particularly important in emissions systems where precise component placement is necessary to meet regulatory standards and ensure optimal engine operation.

Turbocharger Assemblies

For the H2 and H2D turbochargers, as well as the turbocharger core and core assembly, the retaining ring is instrumental in securing the turbine and compressor wheels. This ensures that these critical components operate within their designed parameters, enhancing turbocharger efficiency and durability.

Repair and Performance Kits

In the repair kit for the H2E and the turbocharger repair heat exchanger 50 kit, the retaining ring is used to reassemble components accurately after maintenance or repair. This guarantees that the engine returns to its peak performance levels post-repair.

Turbocharger Actuator and Connection Kits

The turbocharger actuator kit and turbocharger and connection components also benefit from the retaining ring. It ensures that the actuator mechanisms and connection points are securely held in place, which is essential for the precise control of turbocharger operation.

Pre-set Turbine Housing Kit and Performance Parts

In the pre-set turbine housing kit and various performance parts, including the AFC performance parts, the retaining ring helps in maintaining the exact specifications of the turbine housing. This is crucial for achieving the desired performance enhancements in high-performance engine applications.

Conclusion

The 3709753 Retaining Ring is a critical component in the maintenance and operation of Cummins engines. Its role in securing components within various engine systems ensures the reliability and efficiency of the engine. Proper installation, regular maintenance, and understanding its compatibility with different engine models are essential for maximizing the performance and longevity of commercial truck engines.

-

Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, Haoran Hu, Simon J Baseley and Xubin Song, SAE International, 2021

↩ -

Automotive Transmissions Fundamentals Selection Design and Application, Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Springer Vieweg, 2011

↩ -

Crolla Encyclopedia, David Crolla, Wiley, 2015

↩ -

Vocational Vehicles and Applications, Michael Hilgers, Springer Nature, 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.