This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

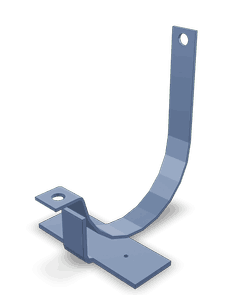

The Cummins 3897034 Retaining Clamp is a component designed to secure various parts within the mechanical systems of commercial trucks. Its role is significant in ensuring the stability and proper functioning of truck components, contributing to the overall efficiency and reliability of the vehicle.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold parts in place. They operate by applying pressure to secure components, preventing movement that could lead to wear, damage, or failure. In mechanical systems, retaining clamps ensure that parts remain aligned and function as intended under operational conditions 1.

Purpose of the Cummins 3897034 Retaining Clamp

The Cummins 3897034 Retaining Clamp is specifically designed to secure components within truck systems. It plays a role in maintaining the integrity of connections and assemblies, ensuring that parts do not shift or become dislodged during operation. This clamp is applied in various truck systems where secure fastening is required to maintain performance and safety.

Key Features

The Cummins 3897034 Retaining Clamp features a durable material composition, typically including high-strength steel or alloy, which provides resistance to corrosion and mechanical stress. Its design includes precision-machined surfaces to ensure a tight and secure fit. Additionally, the clamp may incorporate unique characteristics such as adjustable tension settings to accommodate different application requirements.

Benefits

The Cummins 3897034 Retaining Clamp offers several benefits, including enhanced efficiency through secure component fastening, improved reliability by preventing part dislodgement, and performance enhancements by maintaining optimal alignment and operation of truck systems.

Installation Process

To install the Cummins 3897034 Retaining Clamp, begin by ensuring the area is clean and free of debris. Position the clamp over the components to be secured, ensuring proper alignment. Use the appropriate tools to tighten the clamp to the manufacturer’s specified torque settings. Verify that the components are securely held in place without excessive force.

Troubleshooting Common Issues

Common problems with retaining clamps may include loosening over time, corrosion, or damage from mechanical stress. To address these issues, inspect the clamp regularly for signs of wear or corrosion. Tightening the clamp to the correct torque settings can resolve loosening, while replacing damaged or corroded clamps ensures continued secure fastening.

Maintenance Tips

Regular maintenance of the Cummins 3897034 Retaining Clamp involves periodic inspection for signs of wear, corrosion, or damage. Cleaning the clamp and its surrounding area can prevent buildup that may affect its performance. Following the manufacturer’s guidelines for torque settings during installation or re-tightening ensures the clamp maintains its secure hold.

Safety Considerations

When installing, maintaining, or troubleshooting the Cummins 3897034 Retaining Clamp, it is important to follow safety practices. This includes wearing appropriate personal protective equipment, ensuring the truck is securely parked and the engine is off, and using the correct tools to avoid injury or damage to the clamp or surrounding components.

Cummins Retaining Clamp 3897034 Compatibility

The Cummins Retaining Clamp part number 3897034 is designed to fit seamlessly within various engine configurations. This part is integral in ensuring the secure attachment of components, thereby maintaining the structural integrity and operational efficiency of the engine.

Engine Compatibility

- 6C8.3

- Other Cummins Engines

The retaining clamp is engineered to work with the 6C8.3 engine, providing a reliable connection for various parts. Its design ensures that it can be adapted to other Cummins engines, making it a versatile component across multiple engine models.

This part is crucial for maintaining the alignment and stability of engine components, preventing any unwanted movement that could lead to mechanical failures or inefficiencies. The compatibility of the retaining clamp with the 6C8.3 engine and other Cummins engines underscores its importance in the overall performance and longevity of the engine.

Understanding the Role of Part 3897034 Retaining Clamp in Engine Systems

The part 3897034 retaining clamp is a component in ensuring the secure and efficient operation of various engine systems. Its primary function is to hold components in place, preventing movement that could lead to performance issues or damage.

Application in Heat Exchangers

In heat exchangers, the retaining clamp plays a significant role by securing the heat exchanger components, such as tubes and fins, in their designated positions. This ensures optimal heat transfer efficiency by maintaining the correct spacing and alignment. The clamp helps to withstand the thermal expansion and contraction that occur during engine operation, thus preserving the integrity of the heat exchanger.

Integration with Engine Systems

When integrated with engine systems, the retaining clamp contributes to the stability of various components. For instance, in fuel injection systems, it secures fuel lines and injectors, ensuring they remain in the correct position under varying engine conditions. This stability is vital for maintaining precise fuel delivery and combustion efficiency.

Role in Cooling Systems

In cooling systems, the retaining clamp is used to secure radiator hoses and connections. This prevents leaks and ensures that coolant flows smoothly through the system, maintaining engine temperature within safe operating limits. The clamp’s ability to withstand high temperatures and pressure fluctuations is key to the reliable performance of the cooling system.

Importance in Exhaust Systems

For exhaust systems, the retaining clamp is employed to secure exhaust pipes and catalytic converters. This ensures that the exhaust gases are directed efficiently away from the engine, reducing backpressure and enhancing engine performance. The clamp also helps in minimizing vibrations that could otherwise lead to component fatigue or failure.

Contribution to Electrical Systems

In electrical systems, the retaining clamp is used to secure wiring harnesses and connectors. This ensures that electrical connections remain intact, reducing the risk of shorts or intermittent connections that could affect engine performance and reliability.

By understanding the diverse applications of the part 3897034 retaining clamp, engineers and mechanics can appreciate its importance in maintaining the integrity and efficiency of various engine systems.

Conclusion

The Cummins 3897034 Retaining Clamp is a vital component in the mechanical systems of commercial trucks and engines. Its role in securing components, ensuring stability, and maintaining the efficiency of various systems cannot be overstated. Regular maintenance, proper installation, and adherence to safety practices are essential to maximize the benefits of this Cummins part. Understanding its applications across different engine systems highlights the clamp’s versatility and importance in ensuring the reliable operation of commercial vehicles.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.