This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

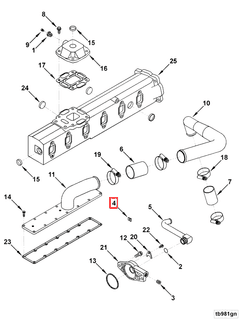

The 3897037 Retaining Clamp, manufactured by Cummins, is a component designed for use in commercial truck maintenance and operation. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part plays a role in ensuring the secure attachment of various parts within the truck’s mechanical systems.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold components in place within a system. They function by applying pressure to secure parts, preventing them from moving or vibrating loose during operation. This is particularly important in the dynamic environment of a commercial truck, where components are subject to constant motion and stress. Retaining clamps come in various designs and materials, tailored to specific applications and the forces they need to withstand 1.

Purpose of the 3897037 Retaining Clamp

The 3897037 Retaining Clamp is designed to secure specific components within a truck’s system, ensuring they remain in place under operational conditions. It plays a role in maintaining the integrity of the truck’s mechanical systems by preventing parts from dislodging or vibrating loose, which could lead to inefficiencies or damage. The clamp supports the operation of the truck by contributing to the stability and reliability of its components.

Key Features

The 3897037 Retaining Clamp is characterized by its robust design and material composition, which are chosen to enhance its performance and durability. It is constructed from materials that offer resistance to wear and corrosion, ensuring longevity in the demanding environment of a commercial truck. The clamp’s design allows for easy installation and adjustment, facilitating its use in various applications.

Benefits of Using the 3897037 Retaining Clamp

Utilizing the 3897037 Retaining Clamp in truck operations offers several advantages. It contributes to improved safety by ensuring components remain securely in place, reducing the risk of accidents caused by part failure. The clamp also enhances the efficiency of the truck by maintaining the integrity of its mechanical systems, leading to smoother operation and potentially lower maintenance costs. Its reliability is a key factor in the consistent performance of the truck.

Installation Process

Installing the 3897037 Retaining Clamp involves several steps to ensure it is correctly positioned and secured. The process begins with identifying the correct location for the clamp within the truck’s system. Once positioned, the clamp is tightened to the manufacturer’s specifications using the appropriate tools. This ensures it applies the necessary pressure to hold components in place without over-tightening, which could damage the parts or the clamp itself.

Troubleshooting Common Issues

Common issues with the 3897037 Retaining Clamp may include loosening over time or damage from wear and tear. To address these problems, it is important to regularly inspect the clamp for signs of wear or corrosion. If the clamp appears loose, it should be re-tightened to the manufacturer’s specifications. In cases of significant damage, replacement may be necessary to ensure the continued reliability of the truck’s mechanical systems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3897037 Retaining Clamp, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the clamp and its surrounding area can prevent the accumulation of debris that may affect its operation. Additionally, ensuring the clamp is correctly tightened during routine maintenance checks can help maintain its effectiveness in securing components.

Compatibility and Applications

The 3897037 Retaining Clamp is designed for use in specific types of trucks and models, where it plays a role in securing components within the vehicle’s mechanical systems. Its compatibility with various truck models ensures it can be effectively utilized across a range of applications, contributing to the reliability and efficiency of commercial truck operations.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to quality and performance is reflected in its parts, including the 3897037 Retaining Clamp 2.

Cummins Retaining Clamp Part 3897037 Compatibility

The Cummins Retaining Clamp part number 3897037 is designed to fit seamlessly with various engine models, ensuring secure and reliable performance. This part is crucial for maintaining the integrity of engine components by providing a firm grip and preventing unwanted movement.

Engine Compatibility

-

6B5.9 Series

- The 3897037 retaining clamp is specifically engineered to fit within the 6B5.9 engine series. This engine is known for its robust design and is often used in heavy-duty applications, where reliability and durability are paramount. The clamp ensures that all connected parts remain stable under high operational stresses.

-

Other Cummins Engines

- While the primary focus is on the 6B5.9 series, the 3897037 retaining clamp is also compatible with other Cummins engines. Its universal design allows it to be used across various models, providing a consistent level of performance and reliability. This versatility makes it a valuable component for technicians and engineers working with multiple engine types.

Installation and Usage

-

Precision Fit

- The retaining clamp is manufactured to precise specifications, ensuring a perfect fit for the designated engine parts. This precision minimizes the risk of misalignment and enhances the overall efficiency of the engine.

-

Durability

- Constructed from high-quality materials, the 3897037 retaining clamp is built to withstand the demanding conditions of engine operation. Its durability ensures a long service life, reducing the need for frequent replacements and maintenance.

-

Ease of Installation

- Designed for straightforward installation, the 3897037 retaining clamp can be easily fitted by technicians. Its user-friendly design allows for quick and efficient assembly, minimizing downtime during maintenance procedures.

Conclusion

The 3897037 Retaining Clamp is an essential component in the secure and efficient operation of various engine systems. Its primary function is to maintain the proper positioning and stability of key elements within the engine’s architecture. By integrating this part into the 6B5.9 engine series and other compatible Cummins engines, users can expect enhanced stability and performance. This part plays a critical role in maintaining the structural integrity of the engine, ensuring that all components function optimally under various operational conditions 3.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.