This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

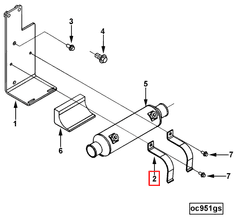

The 3897179 Retainer Clamp is a component designed for use in commercial trucks, manufactured by Cummins. This clamp plays a role in securing various parts within the truck’s engine system, ensuring they remain in place under operational conditions. Cummins, a well-established name in the manufacturing of truck components, is recognized for its commitment to quality and innovation.

Purpose of the 3897179 Retainer Clamp

The 3897179 Retainer Clamp serves to hold components firmly in place within the truck’s engine system. By securing parts such as hoses, wires, or other elements, it contributes to the overall efficiency and safety of the vehicle. Proper installation and maintenance of the clamp help prevent parts from dislodging or vibrating loose, which could lead to performance issues or safety hazards 1.

Basic Concepts Related to Retainer Clamps

A Retainer Clamp is a mechanical device used to hold objects in place. It operates by applying pressure to the object it is securing, often through a screw or lever mechanism. Retainer Clamps are significant in various mechanical systems across industries, providing stability and security to components that might otherwise move or become misaligned during operation 2.

Key Features of the 3897179 Retainer Clamp

The 3897179 Retainer Clamp is constructed with durability in mind, utilizing materials that can withstand the harsh conditions found in commercial truck environments. Its design includes features that enhance its grip and stability, ensuring that it effectively holds components in place. The clamp’s construction allows for easy installation and adjustment, making it a practical choice for maintenance and repair tasks.

Benefits of Using the 3897179 Retainer Clamp

Utilizing the 3897179 Retainer Clamp offers several advantages, including improved performance and reliability of the truck’s engine system. Its design allows for secure fastening of components, reducing the risk of parts becoming dislodged during operation. Additionally, the clamp’s ease of maintenance contributes to the overall efficiency of truck maintenance routines.

Installation Process

Installing the 3897179 Retainer Clamp involves several steps to ensure it is properly secured. The process begins with identifying the correct location for the clamp within the engine system. Tools required for installation may include a wrench or screwdriver, depending on the specific model. Preparation steps involve cleaning the area where the clamp will be installed to ensure a secure fit. Following the manufacturer’s instructions for tightening and adjusting the clamp is crucial to achieve the desired level of security and performance.

Troubleshooting Common Issues

Common problems associated with Retainer Clamps can include loosening over time or difficulty in securing components properly. To address these issues, regular inspections are recommended to identify any signs of wear or improper installation. Adjustments or replacements may be necessary to maintain the clamp’s effectiveness. Diagnostic tips include checking for proper alignment and tension, ensuring that the clamp is not overtightened, which could damage the components it is securing.

Maintenance Tips

Regular maintenance of the 3897179 Retainer Clamp is key to ensuring its longevity and optimal performance. Inspection procedures should be part of routine maintenance checks, looking for signs of wear, corrosion, or damage. Cleaning the clamp and its surrounding area can prevent buildup that might affect its operation. Replacement guidelines suggest that if the clamp shows significant wear or if it fails to secure components effectively, it should be replaced to maintain the safety and efficiency of the truck’s engine system.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the truck components industry, with a history of innovation and quality. The company’s reputation is built on its commitment to producing reliable and efficient parts for commercial vehicles. Cummins’ focus on research and development ensures that its products, including the 3897179 Retainer Clamp, meet the high standards required for modern truck operations.

Compatibility with Cummins Engines

The Retainer Clamp part number 3897179, manufactured by Cummins, is designed to fit seamlessly within specific engine models. This part is integral to the engine’s assembly, ensuring secure connections and maintaining the integrity of various components.

6C8.3 Engine

In the 6C8.3 engine, the Retainer Clamp part 3897179 plays a role in securing certain parts, ensuring that they remain in place under operational conditions. Its precise fit and robust design are essential for maintaining the engine’s performance and longevity.

QSM11 and CM570 Engines

For the QSM11 and CM570 engines, the Retainer Clamp part 3897179 is equally important. These engines, known for their reliability and efficiency, depend on this part to maintain the alignment and stability of various components. The clamp’s design ensures that it can withstand the rigors of engine operation, providing a dependable connection that is critical for the engine’s overall functionality.

The compatibility of the Retainer Clamp part 3897179 across these engines underscores its versatility and importance in Cummins’ engine lineup. Its consistent performance in different engine models highlights the meticulous engineering that goes into Cummins’ parts, ensuring that they meet the high standards required for modern engine applications.

Application in Various Systems

The Retainer Clamp, part number 3897179, is integral to the assembly and maintenance of various engine systems. It ensures secure connections and stability among components, facilitating efficient operation and longevity of the engine.

- Aftercooler System: The Retainer Clamp is used to maintain the integrity of connections between the aftercooler and other components such as hoses or pipes. This ensures that the cooled air is effectively delivered to the engine, enhancing performance and efficiency.

- Cooler System: Whether it be an oil cooler or another type, the Retainer Clamp plays a significant role in securing the connections to and from the cooler. This is essential for maintaining the flow of coolant, which is vital for regulating engine temperature and preventing overheating.

- Marine Gear Oil System: In systems involving marine gear oil, the Retainer Clamp is employed to ensure that the oil lines and connections remain secure. This is particularly important in marine environments where vibrations and movements can loosen connections, leading to potential oil leaks and system failures.

- Oil Cooler: For an oil cooler, the Retainer Clamp is used to secure the connections between the cooler and the engine’s oil system. This ensures that the oil is effectively cooled before it is recirculated, which helps in maintaining optimal engine temperature and prolonging the life of the engine components.

Overall, the Retainer Clamp, part 3897179, is a fundamental component in ensuring that these systems operate efficiently and reliably by maintaining secure and stable connections.

Conclusion

The 3897179 Retainer Clamp by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its role in securing various parts within the engine system ensures the stability and efficiency of the vehicle. With its durable construction, ease of installation, and compatibility with various Cummins engine models, this part contributes significantly to the reliability and performance of commercial trucks. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.