3901693

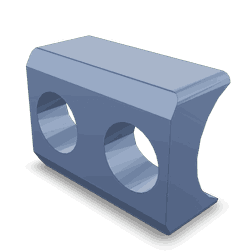

Retaining Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3901693 Retaining Clamp, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts aimed at enhancing the performance and reliability of heavy-duty vehicles. Retaining clamps like the 3901693 play a role in securing various components within a truck’s system, ensuring that they remain in place under operational conditions. This is particularly important in heavy-duty trucks, where components are subjected to significant stress and vibration 1.

Function and Operation

The 3901693 operates on mechanical principles to hold components securely in place. It is designed to exert a consistent clamping force, which helps in maintaining the integrity of connections and joints within the truck’s system. This function contributes to the overall performance and safety of the vehicle by preventing components from loosening or detaching during operation 2.

Purpose of the 3901693 Retaining Clamp

In truck operations, the 3901693 serves the specific role of securing components that are critical to the truck’s function. By ensuring that these components remain firmly in place, the clamp aids in the efficient and safe performance of the truck. This is particularly important in systems where vibrations or movements could lead to component failure or malfunction 3.

Key Features

The 3901693 is characterized by several key features that enhance its functionality and durability. It is constructed from materials that offer high strength and resistance to wear, ensuring longevity under demanding conditions. The design of the clamp includes elements that allow for easy installation and adjustment, while also providing a secure hold on the components it is meant to retain 4.

Benefits

The advantages provided by the 3901693 include improved component security, which leads to enhanced durability and reliability of the truck’s systems. By securely holding components in place, the clamp contributes to the consistent performance of the vehicle, reducing the likelihood of unexpected failures or maintenance issues 5.

Installation Process

Proper installation of the 3901693 involves following a step-by-step process to ensure optimal performance and longevity. Best practices include verifying that the clamp is correctly aligned with the components it is meant to secure, applying the appropriate amount of force to achieve a secure hold, and checking for any signs of wear or damage that could affect its function. Safety precautions, such as wearing appropriate personal protective equipment, should be observed during installation 6.

Troubleshooting and Maintenance

Common issues associated with the 3901693 may include loosening over time due to vibrations or wear. Troubleshooting steps involve inspecting the clamp for signs of damage or wear, ensuring that it is correctly installed, and tightening or replacing it as necessary. Regular maintenance, such as checking the condition of the clamp and ensuring it remains securely in place, can help prolong its lifespan and ensure consistent performance 7.

Safety Considerations

When working with the 3901693, it is important to follow safety guidelines and precautions. This includes using personal protective equipment to protect against potential injuries and ensuring that the work area is safe and free from hazards. Safe handling practices, such as avoiding over-tightening the clamp, are also recommended to prevent damage to the clamp or the components it secures 8.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance truck components, Cummins has established a reputation for excellence. The company’s product range includes a variety of parts designed to enhance the efficiency, reliability, and safety of commercial trucks. Cummins’ dedication to quality is evident in its manufacturing processes and the performance of its products in the field 9.

Compatibility with Cummins Engines

The Retaining Clamp part number 3901693, manufactured by Cummins, is a crucial component in the assembly and operation of several Cummins engine models. This part is designed to securely hold and stabilize various engine components, ensuring optimal performance and longevity of the engine.

Compatibility with Specific Engine Models

-

6C8.3, C8.3 G, G8.3, G8.3 CM558, GTA8.3 CM558, ISL G CM2180, L8.9G CMOH2.0 L125B, L9.3 L105, QSL9 G CM558 The Retaining Clamp 3901693 is compatible with a range of Cummins engines, including the 6C8.3, C8.3 G, G8.3, G8.3 CM558, GTA8.3 CM558, ISL G CM2180, L8.9G CMOH2.0 L125B, L9.3 L105, and QSL9 G CM558. This part is integral in maintaining the structural integrity of these engines by securing various components in place.

-

C GAS PLUS CM556, L GAS PLUS CM556 The Retaining Clamp 3901693 also fits the C GAS PLUS CM556 and L GAS PLUS CM556 engines. These engines, designed for gas applications, rely on this retaining clamp to ensure that all parts remain firmly attached, which is critical for the efficient operation of gas-fueled engines.

By ensuring that the Retaining Clamp 3901693 is correctly installed, engine operators can maintain the reliability and efficiency of their Cummins engines. This part plays a vital role in the overall assembly and functionality of the specified engine models.

Role of Part 3901693 Retaining Clamp in Engine Systems

The Part 3901693 Retaining Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the proper alignment and stability of moving parts, thereby contributing to the overall performance and longevity of the engine.

Lever and Rocker Mechanisms

In engine systems, levers and rockers are often used to transmit motion and force. The Retaining Clamp 3901693 plays a significant role in these mechanisms by securing the lever and rocker in place. This ensures that the motion is transmitted accurately and efficiently without any unwanted movement or misalignment. The clamp helps in reducing wear and tear on the lever and rocker, thus enhancing the durability of these components 10.

Rocker Lever Assemblies

Rocker levers are pivotal in many engine designs, particularly in valvetrain systems. The Retaining Clamp 3901693 is used to hold the rocker lever assembly in its correct position. This is important for maintaining the precise gap between the rocker lever and the valve, which is essential for proper valve operation. By ensuring that the rocker lever remains stable, the clamp contributes to consistent valve timing and efficient engine performance 11.

Short Engine Kit Integration

In short engine kits, which are compact and often used in specialized applications, the Retaining Clamp 3901693 is vital for integrating various components. It secures parts that might otherwise be prone to movement due to the compact nature of the kit. This stability is essential for the reliable operation of the engine, especially under high-stress conditions. The clamp helps in maintaining the integrity of the engine kit, ensuring that all components work in harmony 12.

Overall Engine Stability

Beyond specific components, the Retaining Clamp 3901693 contributes to the overall stability of the engine. By securing moving parts and assemblies, it helps in reducing vibrations and misalignments that can lead to increased wear and potential failures. This results in a more reliable and efficient engine operation, which is beneficial for both performance and maintenance 13.

Conclusion

The 3901693 Retaining Clamp is a critical component in the maintenance and operation of Cummins engines. Its role in securing various engine components ensures the stability, efficiency, and longevity of the engine. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Lakshminarayanan, P. A., and Nayak, Nagaraj S. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

Richards, Paul, and Barker, Jim. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Cummins Inc. X15 CM2350 X114B - Efficiency Series, Service Manual (5411181).

↩ -

Cummins Inc. X15 CM2350 X114B - Efficiency Series, Service Manual (5411181).

↩ -

Cummins Inc. X15 CM2350 X114B - Efficiency Series, Service Manual (5411181).

↩ -

Cummins Inc. X15 CM2350 X114B - Efficiency Series, Service Manual (5411181).

↩ -

Cummins Inc. X15 CM2350 X114B - Efficiency Series, Service Manual (5411181).

↩ -

Cummins Inc. X15 CM2350 X114B - Efficiency Series, Service Manual (5411181).

↩ -

Cummins Inc. X15 CM2350 X114B - Efficiency Series, Service Manual (5411181).

↩ -

Cummins Inc. X15 CM2350 X114B - Efficiency Series, Service Manual (5411181).

↩ -

Cummins Inc. X15 CM2350 X114B - Efficiency Series, Service Manual (5411181).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.