This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

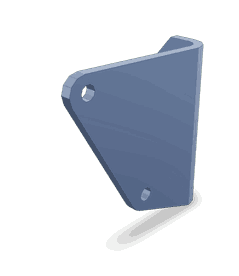

The Cummins 3931665 Retaining Brace Bracket is a component designed for use in commercial trucks. Its purpose is to provide structural support and stability to various parts of the truck’s engine and chassis. This bracket plays a role in maintaining the alignment and integrity of connected components, ensuring the truck operates efficiently and safely 2.

Purpose and Function

In the realm of truck mechanics, the Retaining Brace Bracket serves to secure and stabilize parts of the engine and chassis. By doing so, it contributes to the overall structural integrity of the vehicle. This bracket helps in maintaining the precise alignment of components, which is vital for the operational efficiency of the truck. It ensures that parts remain in their designated positions, reducing the likelihood of mechanical issues arising from misalignment 3.

Key Features

The Cummins 3931665 Retaining Brace Bracket is characterized by its robust design and the quality of materials used in its construction. Typically made from durable metals, this bracket is engineered to withstand the rigors of commercial truck operations. Its design includes features that allow for easy installation and secure fastening, ensuring it remains firmly in place under various driving conditions. Additionally, the bracket may incorporate corrosion-resistant coatings or treatments to enhance its longevity and performance in diverse environments 4.

Benefits

The installation of the Retaining Brace Bracket offers several advantages. Its durable construction contributes to the longevity of the truck’s components by providing reliable support and stability. Enhanced safety is another benefit, as the bracket helps prevent component misalignment, which could lead to operational issues or failures. Over time, the use of this bracket can lead to potential cost savings by reducing the need for frequent repairs or replacements of misaligned or damaged parts 1.

Installation Process

Installing the Cummins 3931665 Retaining Brace Bracket requires careful attention to ensure it is securely fastened and properly aligned. The process involves identifying the correct location for the bracket on the truck’s chassis or engine, using the appropriate tools to attach it, and ensuring all fasteners are tightened to the manufacturer’s specifications. It may be necessary to consult the vehicle’s manual or seek professional assistance to ensure the installation is performed correctly 3.

Maintenance and Troubleshooting

Regular maintenance of the Retaining Brace Bracket is important to ensure its continued effectiveness. This includes checking for signs of wear or damage, ensuring all fasteners remain tight, and addressing any corrosion that may occur. Common issues that may arise include loosening of the bracket or damage from road debris. Troubleshooting these issues typically involves re-securing the bracket or, in more severe cases, replacing it to maintain the structural integrity and operational efficiency of the truck 4.

Compatibility and Applications

The Cummins 3931665 Retaining Brace Bracket is designed for use with specific types of trucks and engine models. Its applications span various commercial trucking scenarios, where it provides the necessary support and stability for engine and chassis components. Understanding the compatibility of this bracket with your truck is important for ensuring optimal performance and longevity 1.

Safety Considerations

When installing or maintaining the Retaining Brace Bracket, it is important to observe safety guidelines and precautions. This includes ensuring the truck is securely supported on a level surface, using the correct tools for installation, and following all manufacturer recommendations. Potential risks, such as injury from falling components or improper installation, can be mitigated by adhering to these safety practices 3.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to quality and innovation in truck components. With a history of producing reliable and high-performance parts, Cummins has established a reputation for excellence. The company’s dedication to advancing truck technology is evident in its wide range of components, designed to enhance the efficiency, durability, and safety of commercial vehicles 1.

Cummins Retaining Brace Bracket 3931665 in Engine Applications

The Cummins Retaining Brace Bracket 3931665 is a critical component in the assembly of several engine models. This part is designed to secure and stabilize various engine parts, ensuring the integrity and performance of the engine. Here’s how it fits into different Cummins engine configurations:

B5.9 G Engine

In the B5.9 G engine, the Retaining Brace Bracket 3931665 plays a pivotal role in maintaining the structural integrity of the engine. It is typically used to secure the engine’s internal components, ensuring they remain in their designated positions under various operational conditions. This bracket is integral in preventing unwanted movement and vibrations that could lead to mechanical failures or reduced efficiency 2.

Application Across Engine Models

While the specific application of the Retaining Brace Bracket 3931665 can vary slightly between different engine models, its fundamental purpose remains consistent. It is a versatile component that can be adapted to fit various engine designs, providing a reliable means of securing and stabilizing critical engine parts. This adaptability makes it a valuable part in the Cummins engine lineup, ensuring that each engine operates smoothly and efficiently 1.

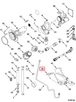

Role of Part 3931665 Retaining Brace Bracket in Engine Systems

The 3931665 Retaining Brace Bracket is an essential component that ensures the structural integrity and proper alignment of various engine systems. It plays a significant role in supporting and securing the evaporator module and the fuel control system, which are vital for the efficient operation of the engine.

Support for the Evaporator Module

The evaporator module is a key component in the engine’s air conditioning system. It is responsible for cooling the air that enters the vehicle’s cabin. The 3931665 Retaining Brace Bracket provides the necessary support to keep the evaporator module firmly in place. This ensures that the module remains stable during engine vibrations and other dynamic conditions, allowing it to function effectively without the risk of displacement or damage 2.

Stabilization of the Fuel Control System

The fuel control system, which includes components like the fuel injectors and fuel rails, requires precise alignment to deliver the correct amount of fuel to the engine cylinders. The 3931665 Retaining Brace Bracket helps in maintaining the alignment and stability of these components. By securing the fuel control system in its designated position, the bracket ensures that fuel delivery remains consistent, contributing to optimal engine performance and fuel efficiency 3.

Integration with Other Components

Beyond its direct support roles, the 3931665 Retaining Brace Bracket also aids in the integration of other engine components. It helps in maintaining the overall structural integrity of the engine bay by providing a stable platform for various systems to interconnect. This integration is vital for the seamless operation of the engine, ensuring that all components work in harmony to deliver peak performance 4.

Conclusion

The Cummins 3931665 Retaining Brace Bracket is a vital component in the maintenance and operation of commercial trucks. Its robust design, durability, and role in securing and stabilizing engine and chassis components contribute to the overall efficiency, safety, and longevity of the vehicle. Proper installation, maintenance, and understanding of its applications are key to leveraging the full benefits of this Cummins part.

-

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ ↩ ↩ ↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ ↩ ↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ ↩ ↩ ↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.