This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3964776 Retaining Clamp is a component designed for use in commercial trucks, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is essential for maintaining and optimizing truck performance.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold components in place within a system. They operate by applying pressure to secure parts, ensuring they remain fixed during operation. This function is vital in various mechanical systems where components must stay aligned and secure to function correctly 1.

Purpose of the Cummins 3964776 Retaining Clamp

This part plays a role in securing specific components within a truck’s system. Its application varies across different truck systems, but its primary function is to maintain the alignment and integrity of parts under operational conditions. This ensures that the components function as intended, contributing to the truck’s overall performance 2.

Key Features

The Cummins 3964776 Retaining Clamp is constructed from durable materials, designed to withstand the rigors of commercial truck operation. Its design includes features that enhance its functionality, such as a robust clamping mechanism that ensures a secure hold on components. Additionally, the clamp is engineered to be compatible with specific truck models, ensuring a precise fit and effective performance 3.

Benefits

The use of the Cummins 3964776 Retaining Clamp offers several advantages. It contributes to improved reliability by securely holding components in place, reducing the risk of misalignment or failure. Its durable construction enhances the longevity of the clamp, providing cost-effective maintenance solutions. Furthermore, by ensuring components operate as intended, the clamp plays a role in maintaining the efficiency of truck operations 4.

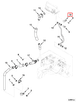

Installation Process

Installing the Cummins 3964776 Retaining Clamp requires following a specific procedure to ensure proper function and safety. The process involves identifying the correct location for the clamp, using the appropriate tools to secure it in place, and verifying that it holds components firmly without causing damage. Safety precautions, such as wearing protective gear and ensuring the truck is turned off, should be observed during installation.

Troubleshooting and Maintenance

Common issues with the Cummins 3964776 Retaining Clamp may include loosening over time or damage from operational stress. Diagnostic procedures involve inspecting the clamp for signs of wear or misalignment and addressing any issues promptly to prevent further complications. Regular maintenance, such as checking the clamp’s condition and ensuring it remains securely fastened, is crucial for optimal performance and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. Its product range is designed to meet the demanding requirements of commercial applications, ensuring reliability, efficiency, and performance.

Understanding the Role of Part 3964776 Retaining Clamp in Engine Systems

This Cummins part is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the integrity of connections and fittings within the engine, thereby contributing to the overall performance and reliability of the engine.

Integration with the Breather System

In the breather system, the retaining clamp plays a significant role by securing the breather hoses and fittings. This system is designed to release pressure build-up within the crankcase, allowing contaminants and moisture to be expelled from the engine. The secure attachment provided by the retaining clamp ensures that the breather system operates without leaks, maintaining optimal pressure levels and preventing the re-entry of contaminants into the engine.

Ensuring Crankcase Integrity

The crankcase is a vital component of the engine, housing the crankshaft and connecting rods. The retaining clamp is used to secure various fittings and hoses connected to the crankcase, such as oil lines and ventilation tubes. By providing a tight and reliable seal, the retaining clamp helps maintain the crankcase’s pressure and prevents oil leaks, which are essential for the engine’s lubrication system to function correctly.

Supporting Efficient Engine Operation

The retaining clamp’s role extends beyond simple attachment; it supports the efficient operation of the engine by ensuring that all connected systems function as intended. Whether it’s securing breather hoses to manage crankcase pressure or attaching oil lines to maintain lubrication, the retaining clamp is a fundamental component in the engine’s design. Its reliable performance contributes to the engine’s durability, efficiency, and overall reliability.

Conclusion

The Cummins 3964776 Retaining Clamp is a critical component in the maintenance and optimization of commercial truck performance. Its role in securing components, ensuring system integrity, and supporting efficient engine operation underscores its importance in the commercial truck industry. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the longevity and reliability of truck operations.

-

Modern Diesel Technology Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Delmar Cengage Learning, 2014.

↩ -

Auto Repair for Dummies: 2nd Edition, Deanna Sclar, For Dummies, 2008.

↩ -

An Introduction to Engine Testing and Development, Richard D. Atkins, SAE International, 2009.

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.