This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

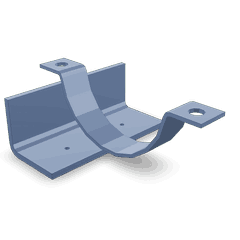

The Cummins 3975228 Retaining Clamp is a component designed to secure various parts within the mechanical systems of commercial trucks. Its role is significant in maintaining the integrity and efficiency of truck operations, ensuring that components remain in place under varying conditions and stresses 3.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold components securely in place. They are integral in various mechanical systems, providing stability and preventing movement that could lead to wear, damage, or failure of the secured parts. Retaining clamps function by applying pressure to the components they are designed to hold, ensuring they remain fixed during operation 1.

Purpose of the 3975228 Retaining Clamp

This Cummins part is specifically designed to secure components within the truck’s engine and transmission systems. It plays a role in maintaining the alignment and stability of parts that are subject to vibration, heat, and mechanical stress. By securing these components, the clamp contributes to the overall reliability and performance of the truck 2.

Key Features

The 3975228 is constructed from durable materials, ensuring it can withstand the harsh conditions of commercial truck environments. Its design includes features such as a robust clamping mechanism and corrosion-resistant properties, which enhance its functionality and longevity. The clamp is also engineered to provide a secure fit without the need for additional fasteners, simplifying the installation process 3.

Benefits of Using the 3975228 Retaining Clamp

Utilizing this part offers several advantages. It improves the reliability of the secured components by preventing movement and misalignment. The ease of installation reduces downtime during maintenance procedures. Additionally, the clamp’s durability can lead to cost savings over time by reducing the need for frequent replacements or repairs 1.

Installation Process

Installing the 3975228 involves positioning it around the component it is designed to secure, then tightening it to the specified torque. This process may require the use of standard tools such as wrenches or sockets. It is important to follow the manufacturer’s guidelines to ensure the clamp is fitted securely and correctly, providing the intended level of component stability 3.

Maintenance and Troubleshooting

Regular maintenance of the 3975228 includes inspecting it for signs of wear, corrosion, or damage. If the clamp shows signs of deterioration, it should be replaced to maintain the security of the components it holds. Troubleshooting common issues may involve checking the clamp’s fit and ensuring it is tightened to the correct specification 2.

Compatibility and Usage

The 3975228 is designed for use in specific models of trucks and engines. It is important to consult Cummins’ guidelines to ensure compatibility with the intended application. Proper usage according to these guidelines will ensure the clamp functions as intended, contributing to the truck’s overall performance and reliability 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and durability of commercial vehicles 3.

Cummins Retaining Clamp 3975228 Compatibility

The Cummins Retaining Clamp part number 3975228 is designed to fit seamlessly with several engine models, ensuring secure and reliable performance. This part is integral to maintaining the integrity of the engine’s components by providing a firm hold on various parts, preventing unwanted movement and ensuring operational efficiency 3.

QSB5.9 CM850 Engines

The QSB5.9 CM850 engines are among the models that benefit from the use of the 3975228 retaining clamp. This engine, known for its robust construction and reliable performance, is often utilized in heavy-duty applications where durability and power are paramount. The retaining clamp plays a role in these engines by securing critical components, thereby enhancing the overall reliability and longevity of the engine 3.

Grouping of Engines

While the 3975228 retaining clamp is specifically designed for the QSB5.9 CM850 engines, it is also compatible with other Cummins engines within the same family or series. This compatibility ensures that users can maintain their engines with confidence, knowing that the retaining clamp is engineered to fit and function optimally across various models. The part’s design and material ensure it can withstand the rigors of demanding environments, providing a long-lasting solution for engine maintenance 3.

Role of Part 3975228 Retaining Clamp in Engine Systems

The retaining clamp, identified by part number 3975228, is integral to the secure assembly and operation of various engine components. Its primary function is to maintain the structural integrity and alignment of parts that are subject to significant stress and vibration during engine operation 2.

Heat Exchanger Applications

In heat exchanger systems, the retaining clamp ensures that the tubes and fins remain firmly in place. This is essential for maintaining the efficiency of heat transfer between the fluid and the surrounding air. The clamp prevents tube misalignment, which could lead to reduced heat exchange efficiency and potential leaks. Additionally, it helps in withstanding the thermal expansion and contraction that occur during engine operation, ensuring a consistent and reliable performance of the heat exchanger 1.

General Engine Component Integration

Beyond heat exchangers, the retaining clamp is utilized in various engine assemblies where components need to be held together under dynamic conditions. For instance, in the integration of sensors and monitoring devices, the clamp secures these elements in place, ensuring they remain operational and accurately report data despite the engine’s vibrations.

In fuel systems, the clamp is used to secure fuel lines and connectors, preventing leaks and ensuring a consistent fuel supply to the engine. This is particularly important in high-performance engines where fuel delivery precision can significantly impact engine performance and efficiency 2.

Conclusion

Overall, the 3975228 plays a significant role in enhancing the durability and reliability of engine systems by ensuring that critical components remain securely in place, operating efficiently under the demanding conditions of engine operation 3.

-

Critical Component Wear in Heavy Duty Engines, P. A. Lakshminarayanan and Nagaraj S. Nayak, John Wiley & Sons, 2011

↩ ↩ ↩ -

Diesel Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2014

↩ ↩ ↩ ↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.