This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4014068 Isolator Retainer, a component manufactured by Cummins, is integral to the operational efficiency of commercial trucks. This part contributes to the overall performance and longevity of the vehicle by managing vibrations and enhancing engine stability 1.

Function and Operation

This Cummins part plays a role in the truck’s system by managing vibrations and contributing to engine stability. It is positioned to absorb and dampen the vibrations generated by the engine, which if left unchecked, could lead to increased wear on the engine and other connected components. By effectively managing these vibrations, the Isolator Retainer helps maintain a stable engine operation, which is vital for the smooth running of the truck 2.

Key Features

The 4014068 is characterized by several features that enhance its performance. It is constructed from materials that offer durability and resistance to the harsh conditions typically encountered in commercial truck operations. The design of the Isolator Retainer incorporates engineering specifications that ensure it can effectively perform its function under various operational stresses. Additionally, its composition and design elements are tailored to provide optimal vibration management 3.

Benefits of Using the 4014068 Isolator Retainer

Incorporating this part into a truck’s system can lead to several advantages. It contributes to improved engine performance by ensuring that the engine operates in a stable environment, free from excessive vibrations. This stability can reduce the wear and tear on engine components, leading to extended component life and reduced maintenance needs. Furthermore, the overall reliability of the truck is enhanced, as the Isolator Retainer helps prevent issues that could arise from unchecked vibrations 4.

Installation Process

Installing the 4014068 requires adherence to a specific process to ensure it functions correctly. The installation should begin with the truck being securely supported and the engine turned off. The existing isolator, if present, should be removed carefully to avoid damage to surrounding components. The new Isolator Retainer should then be positioned and secured according to the manufacturer’s guidelines, ensuring it is properly aligned and tightened to the specified torque settings. Throughout the installation, it is important to avoid common pitfalls such as over-tightening, which could damage the component, or improper alignment, which could affect its performance 5.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the 4014068, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, and ensuring that it remains securely fastened. Common issues that may arise include reduced effectiveness in vibration management, which could indicate wear or failure of the Isolator Retainer. In such cases, troubleshooting should involve a thorough inspection of the component and its mounting, with replacement or repair as necessary 6.

Safety Considerations

When handling, installing, or maintaining the 4014068, it is important to observe safety guidelines to protect personnel and the truck. This includes ensuring the truck is securely supported during any work, using the correct tools for installation and maintenance, and following all manufacturer guidelines to avoid injury or damage to the vehicle 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial truck operations, with the 4014068 being one example of its commitment to enhancing truck performance and reliability 8.

Compatibility with Cummins Engines

The Isolator Retainer part 4014068 is designed to fit seamlessly with a range of Cummins engines. This part is crucial for maintaining the structural integrity and operational efficiency of the engines by ensuring that the engine isolators are properly secured.

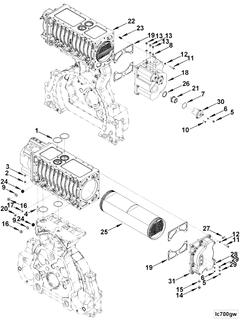

QSV81G and QSV91G Engines

The Isolator Retainer part 4014068 is compatible with both the QSV81G and QSV91G engines. These engines are part of Cummins’ QSV series, known for their robust performance and reliability in various applications. The isolator retainer ensures that the engine isolators are firmly in place, reducing vibrations and noise, which in turn enhances the longevity and performance of the engines 9.

QSW/QSV82 and QSW73 Engines

Similarly, the Isolator Retainer part 4014068 is also suitable for the QSW/QSV82 and QSW73 engines. These engines are part of the QSW series, which is designed for heavy-duty applications. The isolator retainer plays a vital role in these engines by maintaining the stability of the engine mounts, which is essential for the smooth operation of the engines under heavy loads and demanding conditions 10.

Role of Part 4014068 Isolator Retainer in Engine Systems

The 4014068 is an essential component in the arrangement of various engine systems, particularly those involving the engine oil cooler. This part ensures the secure and efficient operation of the cooler assembly core within the engine oil cooler system.

In the context of the engine oil cooler, the Isolator Retainer plays a significant role in maintaining the structural integrity of the cooler core. It helps in securing the cooler core in place, preventing any unwanted movement that could lead to inefficiencies or damage. This is particularly important in high-stress environments where the engine oil cooler is subjected to significant thermal and mechanical stresses 11.

Furthermore, the Isolator Retainer is integral to the engine oil assembly cooler. It ensures that the cooler remains firmly attached to the engine oil system, facilitating optimal heat exchange. This is vital for maintaining the engine oil at the desired temperature, which in turn ensures the engine operates within its specified parameters 12.

Additionally, within the cooler assembly, the Isolator Retainer aids in the precise alignment of components. This alignment is necessary for the efficient flow of engine oil through the cooler, ensuring that the oil is adequately cooled before it is recirculated through the engine 13.

Conclusion

In summary, the 4014068 Isolator Retainer is a key component in the effective functioning of the engine oil cooler system. Its role in securing and aligning the cooler core and assembly ensures that the engine oil is efficiently cooled, contributing to the overall performance and longevity of the engine.

-

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Cummins Inc. (n.d.). Service Manual (5579957).

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Cummins Inc. (n.d.). Service Manual (5579957).

↩ -

Cummins Inc. (n.d.). Service Manual (5579957).

↩ -

Cummins Inc. (n.d.). Service Manual (5579957).

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Cummins Inc. (n.d.). Service Manual (5579957).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.