This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

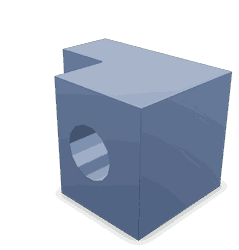

The 4020162 Retaining Clamp, manufactured by Cummins, is a crucial component in the commercial truck industry. Designed for use in commercial trucks, this part secures various components, ensuring the reliable operation of the vehicle.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices that hold components in place within a system by applying pressure, preventing movement and ensuring stability 1. They are essential for maintaining the integrity and alignment of parts in mechanical systems, contributing to the overall performance and safety of the machinery 2.

Purpose of the 4020162 Retaining Clamp

The 4020162 Retaining Clamp is designed to secure components within the truck’s systems, ensuring they remain in the correct position under operational conditions. This contributes to the stability and efficiency of the truck’s mechanical systems by preventing component displacement.

Key Features

This Cummins part boasts several key features that enhance its functionality. It is constructed from durable materials, ensuring longevity and resistance to wear. The design incorporates elements that allow for easy installation and adjustment, facilitating its use in various applications. Additionally, the clamp features a robust mechanism that provides a secure hold on components, contributing to the overall reliability of the truck’s systems.

Benefits

Utilizing the 4020162 Retaining Clamp offers several advantages. Its durable construction and secure hold contribute to improved reliability and efficiency in truck operations. The clamp’s design also allows for easy maintenance, reducing downtime and enhancing the truck’s operational lifespan.

Installation Process

Installing the 4020162 Retaining Clamp involves several steps to ensure proper placement and function. Begin by identifying the component that requires securing. Position the clamp around the component, ensuring it is aligned correctly. Use the appropriate tools to tighten the clamp, applying even pressure to achieve a secure hold. Verify the component’s stability before completing the installation.

Common Issues and Troubleshooting

Retaining clamps, including the 4020162, may encounter issues such as loosening over time or damage from operational stress. To address these problems, regularly inspect the clamp for signs of wear or displacement. If loosening is detected, retighten the clamp to restore its secure hold. In cases of damage, assess the extent of the issue and replace the clamp if necessary to maintain system integrity 3.

Maintenance Tips

To ensure the longevity and optimal performance of the 4020162 Retaining Clamp, incorporate regular maintenance practices into your truck’s service routine. Inspect the clamp during routine checks for signs of wear, corrosion, or displacement. Clean the clamp and its surrounding area to remove debris that could affect its function. Lubricate moving parts as recommended by the manufacturer to facilitate smooth operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Role of Part 4020162 Retaining Clamp in Engine Systems

The 4020162 Retaining Clamp is instrumental in ensuring the integrity and efficiency of various engine system connections. Its application is particularly significant in the following areas:

Exhaust Outlet Connection

In the context of the exhaust outlet, the 4020162 Retaining Clamp secures the connection between the exhaust manifold and the exhaust pipe. This ensures a tight seal, which is essential for maintaining the efficiency of the exhaust system. A secure connection prevents exhaust leaks, which can lead to decreased engine performance and increased emissions. The clamp’s role here is to withstand the high temperatures and pressures generated during engine operation, ensuring a consistent and reliable seal.

Exhaust Connection

For the exhaust connection, the 4020162 Retaining Clamp is used to join various sections of the exhaust system, such as the catalytic converter to the muffler or the muffler to the tailpipe. This connection is vital for the smooth flow of exhaust gases from the engine to the atmosphere. The clamp provides the necessary tension to keep these components firmly in place, reducing the risk of vibrations and disconnections that could otherwise occur due to the engine’s operation.

General Connection Applications

Beyond specific exhaust applications, the 4020162 Retaining Clamp is also employed in other engine system connections where a secure and durable bond is required. This includes connections in the intake system, where it ensures that air enters the engine without leaks, and in cooling systems, where it maintains the integrity of hose connections. The clamp’s versatility makes it a valuable component in various engine systems, contributing to overall engine reliability and performance.

Conclusion

The 4020162 Retaining Clamp plays a significant role in the reliable operation of commercial trucks by securing various components within the engine systems. Its durable construction, ease of installation, and maintenance make it a valuable asset in ensuring the stability and efficiency of truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.