This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4070248 Retaining Clamp is a specialized component designed for use in commercial trucks. Its purpose is to secure various parts and assemblies within the truck’s systems, ensuring they remain in place under operational conditions. The significance of this clamp lies in its ability to enhance the reliability and performance of the truck by maintaining the integrity of critical connections and components 1.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold parts together or in place. They operate by applying a consistent clamping force, which prevents movement and ensures that components remain securely attached. In mechanical systems, retaining clamps play a vital role in maintaining the alignment and stability of parts, which is essential for the efficient operation of the system 2.

Purpose of the 4070248 Retaining Clamp

The Cummins 4070248 Retaining Clamp is specifically designed to secure components within various truck systems. It is commonly used in applications where parts need to be held firmly in place to ensure proper function and safety. This clamp helps in maintaining the structural integrity of assemblies, preventing wear and tear, and reducing the risk of component failure 3.

Key Features

The Cummins 4070248 Retaining Clamp boasts several key features that enhance its functionality. It is constructed from durable materials, ensuring longevity and resistance to wear. The design includes precision-engineered elements that allow for easy installation and reliable performance. Additionally, the clamp may feature unique characteristics such as adjustable clamping force or corrosion-resistant coatings, which further improve its effectiveness in demanding environments.

Benefits

The advantages provided by the Cummins 4070248 Retaining Clamp include improved system reliability, as it ensures that components remain securely in place. This leads to enhanced performance and reduced maintenance needs. The clamp’s design also facilitates ease of installation, allowing for quick and efficient setup. Furthermore, its robust construction contributes to long-term durability, minimizing the need for frequent replacements.

Installation Process

Proper installation of the Cummins 4070248 Retaining Clamp involves several steps. First, ensure that the area where the clamp will be installed is clean and free of debris. Next, position the clamp around the components it is intended to secure. Use the appropriate tools to tighten the clamp, ensuring that it applies consistent pressure across the entire assembly. Verify that the components are held firmly in place and make any necessary adjustments to achieve the desired clamping force.

Common Issues and Troubleshooting

Common problems associated with retaining clamps include improper installation, which can lead to insufficient clamping force or component misalignment. To address these issues, carefully review the installation process to ensure all steps are followed correctly. If the clamp appears loose or misaligned, re-tighten or re-position it as needed. Regular inspections can help identify and resolve potential problems before they lead to more significant issues.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4070248 Retaining Clamp, regular maintenance is recommended. Inspect the clamp periodically for signs of wear or damage. Clean the clamp and surrounding areas to remove any buildup that could affect its function. If the clamp shows signs of corrosion, apply a protective coating to prevent further degradation. Additionally, ensure that the clamping force remains consistent over time by periodically checking and adjusting as necessary.

Safety Considerations

When working with the Cummins 4070248 Retaining Clamp, it is important to observe several safety guidelines. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential injuries. Ensure that the truck is properly secured and the engine is turned off before beginning any installation or maintenance work. Follow all manufacturer recommendations for handling and installation to avoid accidents and ensure safe operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial transportation.

Cummins Retaining Clamp Part 4070248 Compatibility

The Cummins Retaining Clamp part number 4070248 is designed to fit seamlessly within various engine configurations, ensuring secure and reliable performance. This part is integral to maintaining the integrity of the engine’s components by providing a firm hold on specific parts, preventing unwanted movement and ensuring operational efficiency.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the retaining clamp part 4070248 is used to secure various components, ensuring that they remain in place under the high stress and varying conditions of engine operation. This clamp is crucial for maintaining the alignment and stability of parts that are subject to significant mechanical forces, thereby contributing to the overall durability and performance of the engine.

Grouping of Engines

The retaining clamp part 4070248 is compatible with a range of Cummins engines, particularly those within the N14 MECHANICAL family. This part is engineered to fit precisely within these engines, providing a reliable solution for securing components and ensuring that the engine operates smoothly and efficiently. The compatibility of this part with the N14 MECHANICAL engines highlights its versatility and importance in maintaining engine integrity.

Role of Part 4070248 Retaining Clamp in Engine Systems

The part 4070248 retaining clamp is a vital component in ensuring the secure and efficient operation of various engine systems. Its primary function is to hold components in place, preventing movement that could lead to performance issues or damage.

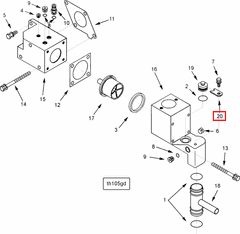

Housing

In engine systems, the housing serves as a protective enclosure for various components, including sensors, pumps, and other critical parts. The retaining clamp, part 4070248, plays a significant role in securing the housing to its designated position. This ensures that the housing remains stable under varying operational conditions, such as vibrations and temperature fluctuations. By maintaining the housing’s integrity, the clamp helps protect the enclosed components from external elements and ensures they function within specified parameters.

Thermostat

The thermostat is a temperature-sensitive valve that regulates the flow of coolant within the engine. Proper installation and secure placement of the thermostat are vital for maintaining optimal engine temperature. The retaining clamp, part 4070248, is used to hold the thermostat in place, ensuring it does not shift or become dislodged during engine operation. This stability is essential for consistent coolant flow, which in turn helps prevent overheating and ensures the engine operates within its designed temperature range.

By effectively securing these components, the part 4070248 retaining clamp contributes to the overall reliability and performance of the engine system.

Conclusion

The Cummins 4070248 Retaining Clamp is a critical component in the maintenance and operation of commercial truck engines. Its role in securing various parts and assemblies ensures the reliability and performance of the truck’s systems. With its durable construction, precision-engineered design, and compatibility with a range of Cummins engines, this part plays a significant role in maintaining the integrity and efficiency of engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.