This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

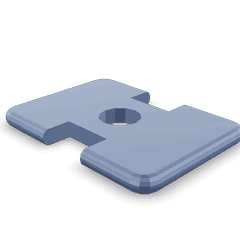

The Cummins 4080902 Retaining Clamp is a component designed for use in commercial trucks. It plays a role in securing components within the truck’s system, ensuring they remain in place under various operating conditions. Understanding its role and significance can help in maintaining and optimizing truck performance.

Purpose and Function

This Cummins part is applied in systems where vibration and movement could otherwise lead to component failure or misalignment. By holding parts firmly in position, it supports the integrity and function of the systems it is part of.

Key Features

The design of the 4080902 incorporates materials and construction techniques that enhance its durability and effectiveness. It is made from high-strength materials to withstand the rigors of commercial truck operation. Its design allows for easy installation and removal, facilitating maintenance procedures. Additionally, the clamp features a secure locking mechanism to ensure components remain fixed in place.

Benefits

Incorporating the 4080902 into a truck’s system offers several advantages. It contributes to improved reliability by preventing component displacement. Its durable construction ensures longevity, reducing the need for frequent replacements. Moreover, by maintaining component alignment, it supports the efficient operation of the truck’s systems, potentially leading to better overall performance.

Installation Process

Installing the 4080902 requires following a series of steps to ensure it is correctly fitted. Begin by identifying the location where the clamp will be installed. Use the appropriate tools to secure the clamp in place, ensuring it is tightly fastened. Verify that the components it is holding are properly aligned and that the clamp’s locking mechanism is engaged. It is important to consult the truck’s maintenance manual for specific instructions and torque specifications.

Maintenance Tips

To ensure the longevity and optimal performance of the 4080902, regular maintenance is recommended. Inspect the clamp during routine maintenance checks to ensure it remains securely fastened and shows no signs of wear or damage. Cleaning the clamp and its surrounding area can prevent the accumulation of debris that might affect its function. If any issues are detected, addressing them promptly can prevent more significant problems.

Troubleshooting Common Issues

Common issues with the 4080902 may include loosening over time or damage due to wear and tear. If the clamp becomes loose, tightening it according to the manufacturer’s specifications can resolve the issue. For damaged clamps, replacement is recommended to maintain system integrity. Regular inspections can help identify potential problems before they lead to component failure.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and automotive markets. The company is known for its comprehensive product range and commitment to customer satisfaction, making it a reputable name in the commercial truck industry.

Cummins Retaining Clamp Part 4080902 in Engine Applications

The Cummins Retaining Clamp part number 4080902 is a component in various engine configurations, ensuring the secure attachment of specific parts within the engine assembly. This retaining clamp is designed to maintain the integrity of engine components by providing a reliable grip and preventing movement that could lead to mechanical failure.

V903 Engines

In the V903 engine series, the retaining clamp part 4080902 is used to secure certain internal components, ensuring that they remain in their designated positions under the high stress and varying conditions of engine operation. The V903 engines, known for their robust design and performance, benefit from the precision and reliability of this retaining clamp, which helps maintain the alignment and stability of parts that are crucial for the engine’s operation.

Application Across Cummins Engines

The versatility of the Cummins Retaining Clamp part 4080902 extends beyond the V903 series. It is also utilized in other Cummins engine models where similar retention requirements are present. This part’s design allows it to fit seamlessly into the engine’s architecture, providing a secure hold that is essential for the engine’s longevity and efficiency.

The use of part 4080902 in Cummins engines underscores the importance of precise engineering and quality materials in engine components. By ensuring that parts remain fixed and do not shift during operation, this retaining clamp contributes to the overall reliability and performance of the engine.

Role of Part 4080902 Retaining Clamp in Engine Systems

The 4080902 retaining clamp is a component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the integrity and alignment of components within the engine, thereby contributing to the overall performance and reliability of the system.

Integration with Aid Systems

In auxiliary systems designed to support engine operation, the 4080902 retaining clamp plays a significant role. These systems often include components such as sensors, wiring harnesses, and auxiliary pumps. The retaining clamp ensures that these elements remain firmly in place, preventing vibrations or movements that could lead to malfunctions or failures. By securing these components, the clamp helps maintain the precision required for the aid systems to function correctly, ultimately supporting the engine’s performance.

Application in Injection Systems

In fuel injection systems, the 4080902 retaining clamp is instrumental in securing fuel lines, injectors, and associated wiring. Fuel injection systems demand high precision to deliver the correct fuel-air mixture to the combustion chamber. The retaining clamp ensures that fuel lines are held taut and in the correct position, minimizing the risk of leaks or disruptions in fuel delivery. Additionally, it secures injectors in place, ensuring they operate within the specified parameters for optimal combustion efficiency. This stability is vital for maintaining the engine’s power output and fuel economy.

Contribution to Starting Systems

The starting system of an engine relies on several components working in unison, including the starter motor, battery connections, and ignition wiring. The 4080902 retaining clamp contributes to the reliability of these systems by ensuring that all electrical connections and mechanical components are held securely in place. This is particularly important during the starting process, where high currents and mechanical stresses are present. By preventing loose connections or misaligned components, the retaining clamp helps ensure a consistent and reliable start-up sequence, reducing the likelihood of starting issues or electrical failures.

Conclusion

The Cummins 4080902 Retaining Clamp is a vital component in the maintenance and operation of commercial trucks and engines. Its role in securing components, ensuring system integrity, and contributing to the overall efficiency and reliability of the vehicle cannot be overstated. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring the longevity and performance of the truck’s systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.