This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

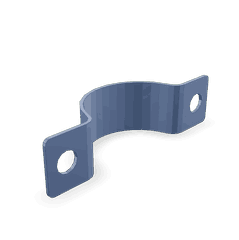

The 4357339 Retaining Clamp, a component manufactured by Cummins, plays a significant role in the commercial truck industry, contributing to the efficiency and reliability of truck systems.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices designed to hold components in place within a system. They ensure the integrity and performance of various mechanical components by securing parts that might otherwise move or become misaligned under operational stress. In truck systems, retaining clamps maintain the alignment and stability of critical components, which is vital for the smooth operation of the vehicle 1.

Purpose of the 4357339 Retaining Clamp

The 4357339 Retaining Clamp is designed to secure specific components within Cummins engines and associated systems. Its role is to maintain the proper positioning of parts that are subject to vibration and movement during engine operation. By doing so, it contributes to the stability and efficiency of the engine, ensuring that components function as intended without undue wear or failure 2.

Key Features

This Cummins part is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operation. Its design includes features that enhance its functionality, such as a secure grip mechanism that ensures components remain firmly in place. The clamp is also engineered to be easy to install and remove, facilitating maintenance and repair processes 3.

Benefits

The advantages of using the 4357339 Retaining Clamp include improved reliability and durability of the truck’s engine and associated systems. By securely holding components in place, it reduces the risk of part misalignment or failure, leading to more efficient truck operations. Additionally, its robust construction ensures longevity, contributing to the overall cost-effectiveness of truck maintenance.

Installation Process

Installing the 4357339 Retaining Clamp involves several steps to ensure it is properly secured. First, the area where the clamp will be installed should be cleaned and inspected for any damage. The clamp is then positioned over the component it is designed to secure, and the grip mechanism is activated to hold the component in place. Tools required for installation may include a wrench or screwdriver, depending on the specific design of the clamp.

Common Issues and Troubleshooting

Typical problems with the 4357339 Retaining Clamp may include loosening over time due to vibration or wear on the grip mechanism. Troubleshooting involves inspecting the clamp for signs of wear or damage and ensuring it is properly secured. If issues are detected, the clamp may need to be retightened or replaced to maintain the integrity of the secured component.

Maintenance Tips

Regular maintenance of the 4357339 Retaining Clamp is important to ensure its continued effectiveness. This includes periodic inspection for signs of wear or damage and ensuring it remains securely fastened. Cleaning the clamp and its surrounding area can also help prevent buildup that might affect its performance. Following these maintenance tips can help extend the lifespan of the clamp and ensure optimal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

Cummins Engine Part 4357339: Retaining Clamp Compatibility

The Cummins part number 4357339, a Retaining Clamp, is a critical component in the assembly of several Cummins engine models. This part is designed to secure various engine components, ensuring they remain in place during operation.

QSK19 CM850 MCRS and QSK60 CM850 MCRS

The QSK19 CM850 MCRS and QSK60 CM850 MCRS engines share a common architecture, particularly in their use of the CM850 engine block. The retaining clamp part 4357339 is utilized in these engines to secure components such as fuel injectors, turbochargers, and other critical parts. Its placement is crucial for maintaining the integrity of the engine’s internal systems, ensuring that parts do not shift or become dislodged under operational stress.

QSK50 CM2150 K107 and QSK50 CM2150 MCRS

The QSK50 CM2150 K107 and QSK50 CM2150 MCRS engines, while distinct from the CM850 models, also incorporate the retaining clamp part 4357339 in their design. This part is essential for securing components such as the exhaust manifold, fuel injectors, and other critical parts that require precise alignment and stability. The clamp’s role in these engines is to maintain the structural integrity of the engine, ensuring that all parts function correctly and efficiently.

Application Across Engine Models

The retaining clamp part 4357339 is a versatile component that finds application across multiple Cummins engine models. Its design and functionality are tailored to meet the specific needs of each engine type, ensuring that it provides reliable performance and durability. Whether securing components in the CM850 or CM2150 engine blocks, this part is integral to the overall operation and longevity of the engine.

Role of Part 4357339 Retaining Clamp in Engine Systems

The part 4357339 retaining clamp is an essential component in the secure and efficient operation of various engine systems. Its primary function is to hold components in place, ensuring they remain fixed during engine operation, which is vital for the overall performance and longevity of the engine.

Application in Fuel Systems

In fuel systems, the retaining clamp is used to secure fuel lines and connectors. This ensures a tight seal, preventing fuel leaks that could lead to dangerous situations. By maintaining the integrity of the fuel lines, the clamp contributes to consistent fuel delivery to the engine, which is necessary for optimal combustion and engine efficiency.

Integration with Filters

When it comes to filters, such as oil or air filters, the retaining clamp plays a significant role in keeping these components securely attached to their respective housings. This is important for several reasons:

- Seal Integrity: A secure fit ensures that the filter creates a proper seal, preventing contaminants from bypassing the filter and entering the engine.

- Vibration Resistance: Engines experience significant vibrations during operation. The retaining clamp helps to counteract these vibrations, ensuring that the filter remains firmly in place.

- Maintenance Ease: For routine maintenance, such as filter changes, the retaining clamp allows for quick and secure attachment and detachment, facilitating easier and faster service procedures.

Overall Engine System Contribution

Beyond specific components like filters and fuel lines, the retaining clamp is instrumental in the broader context of engine systems. It helps in:

- Reducing Wear and Tear: By keeping components securely in place, the clamp reduces the likelihood of parts rubbing against each other, which can lead to premature wear.

- Enhancing Safety: Securely fastened components are less likely to dislodge or fail during engine operation, enhancing the safety and reliability of the engine system.

- Improving Performance: Consistent and secure component attachment ensures that the engine operates within its designed parameters, leading to improved performance and fuel efficiency.

Conclusion

In summary, the 4357339 retaining clamp is a fundamental component in maintaining the structural integrity and operational efficiency of engine systems, particularly in fuel delivery and filter applications. Its role in securing components ensures the reliability, safety, and performance of Cummins engines, contributing to the overall efficiency and longevity of commercial truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.