This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

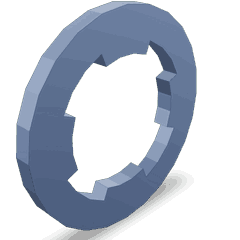

The 4385555 Retaining Ring, manufactured by Cummins, is a component used in commercial trucks. Cummins, a well-established name in the automotive industry, produces a range of parts designed to enhance the performance and reliability of heavy-duty vehicles. This Cummins part is specifically engineered to meet the demanding requirements of commercial truck operations, ensuring components remain securely in place under various operating conditions.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing 1. They function by creating a secure fit that holds parts in place, preventing axial movement. Retaining rings are commonly used in various mechanical systems to ensure the stability and integrity of assemblies. They are typically made from spring steel, which provides the necessary strength and flexibility for their application.

Purpose of the 4385555 Retaining Ring in Truck Operations

In commercial trucks, the 4385555 Retaining Ring plays a role in securing components within the engine and transmission systems. It is associated with shafts, gears, and other rotating parts, ensuring they remain in the correct position during operation. This helps maintain the alignment and performance of the truck’s mechanical systems, contributing to overall reliability and efficiency 2.

Key Features of the 4385555 Retaining Ring

The 4385555 Retaining Ring is designed with several features that make it suitable for its intended applications. It is constructed from high-quality spring steel, providing durability and resistance to wear. The ring’s design includes precise tolerances to ensure a secure fit, while its material composition allows it to withstand the high stresses and temperatures encountered in commercial truck operations. Additionally, the ring is engineered to be easy to install and remove, facilitating maintenance procedures.

Benefits of Using the 4385555 Retaining Ring

The 4385555 Retaining Ring offers several advantages for commercial truck applications. Its robust construction enhances the reliability of the components it secures, reducing the risk of failure during operation. The ring’s design allows for straightforward installation, minimizing downtime during maintenance. Furthermore, its durability contributes to longer service intervals, providing cost-effective operation for fleet managers 3.

Installation Process

Installing the 4385555 Retaining Ring requires careful attention to ensure proper fit and function. The process involves the following steps:

- Clean the shaft or housing where the ring will be installed to remove any debris or contaminants.

- Use retaining ring pliers to expand the ring and place it over the end of the shaft or into the groove in the housing.

- Release the pliers, allowing the ring to contract and secure the component in place.

- Verify that the ring is seated correctly and that the component is held firmly without excessive movement.

Troubleshooting Common Issues

Common issues with the 4385555 Retaining Ring may include improper seating, damage from installation, or wear over time. To address these problems:

- Ensure the ring is the correct size for the application and that it is installed in the proper orientation.

- Inspect the ring for signs of damage or deformation before installation.

- Regularly check the ring during maintenance intervals for signs of wear or movement, and replace it if necessary to maintain system integrity.

Maintenance Tips

To ensure the longevity and proper function of the 4385555 Retaining Ring, regular maintenance is recommended. Inspect the ring during routine service checks for signs of wear, corrosion, or damage. Clean the ring and its seating area to remove any buildup that could affect its performance. Replace the ring if it shows signs of significant wear or if it no longer provides a secure fit. Adhering to these maintenance practices will help maintain the reliability of the truck’s mechanical systems.

Cummins: Manufacturer Overview

Cummins is a leading manufacturer in the automotive and heavy-duty truck industry, known for its high-quality engines, components, and systems. With a history spanning over a century, Cummins has established a reputation for innovation, reliability, and performance. The company offers a wide range of products designed to meet the needs of commercial vehicle operators, including engines, powertrain components, and aftermarket parts. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Cummins Part 4385555: Retaining Ring Compatibility

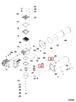

The Cummins part 4385555, a Retaining Ring, is designed to fit seamlessly within several of the company’s engine models. This part is crucial for maintaining the integrity of engine components by preventing unwanted movement and ensuring that parts remain securely in place.

QSK95 and CM2350 Engines

The QSK95 and CM2350 engines, both part of Cummins’ heavy-duty diesel engine lineup, benefit from the use of the 4385555 Retaining Ring. These engines are known for their robust performance and reliability in demanding applications, such as power generation and industrial use. The retaining ring ensures that critical components within these engines remain fixed, contributing to the overall efficiency and longevity of the engine.

K113 Engine

The K113 engine, another member of Cummins’ extensive engine family, also utilizes the 4385555 Retaining Ring. This engine is typically employed in medium-duty applications, where it provides a balance of power and efficiency. The retaining ring’s role in the K113 engine is to maintain the stability of various parts, ensuring that the engine operates smoothly and reliably under different conditions.

Grouping Engines for Efficiency

When considering the QSK95, CM2350, and K113 engines, it is evident that the 4385555 Retaining Ring serves a critical function across these models. By ensuring that components remain securely in place, this part helps maintain the high standards of performance and durability that Cummins engines are known for. The use of a standardized part across multiple engine types also simplifies maintenance and repair processes, making it easier for technicians to service these engines effectively.

Role of Part 4385555 Retaining Ring in Engine Systems

The 4385555 Retaining Ring is an essential component in ensuring the secure assembly and operation of various engine systems. Its application spans across multiple subsystems, contributing to the overall efficiency and reliability of the engine.

Accessories

In the accessories section of an engine, the 4385555 Retaining Ring is often used to secure components such as pulleys, brackets, and mounting hardware. These accessories are vital for the operation of ancillary systems like the alternator, air conditioning compressor, and power steering pump. The retaining ring ensures that these components remain firmly in place, preventing misalignment and potential damage during engine operation.

Fuel System

Within the fuel system, the 4385555 Retaining Ring plays a significant role in maintaining the integrity of connections. It is commonly employed in fuel injectors, where it secures the injector body to the fuel rail. This ensures a leak-free connection, which is essential for maintaining fuel pressure and delivering the correct fuel-air mixture to the combustion chambers. Additionally, the retaining ring is used in fuel pump modules to secure the pump to the housing, ensuring stable operation and preventing fuel leaks.

Fuel Filter

In the fuel filter assembly, the 4385555 Retaining Ring is utilized to secure the filter element within its housing. This is important for maintaining the filter’s efficiency in removing contaminants from the fuel. A secure fit prevents bypass flow, ensuring that only clean fuel reaches the engine. This contributes to better engine performance and longevity by reducing the risk of fuel system contamination.

Service Kit

Service kits often include the 4385555 Retaining Ring as a replacement part for various engine components. During maintenance procedures, worn or damaged retaining rings are replaced to ensure that all assemblies remain secure. This is particularly important in high-wear areas such as the valve train, where retaining rings secure components like valve springs and keepers. Proper installation of these rings during a service ensures that the engine continues to operate smoothly and efficiently.

Conclusion

The 4385555 Retaining Ring is a vital component in the operation and maintenance of Cummins engines, particularly in commercial truck applications. Its robust design, ease of installation, and compatibility with various engine models make it an essential part for ensuring the reliability and efficiency of heavy-duty vehicles. Regular maintenance and proper installation practices are crucial for maximizing the benefits of this part, contributing to the overall performance and longevity of the engine systems it supports.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.