This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4900420 Retaining Ring is a specialized component designed for use in commercial trucks. Its primary function is to secure various parts within the truck’s engine and transmission systems, ensuring they remain in place under operational conditions. This retaining ring is integral to maintaining the structural integrity and performance of critical components in heavy-duty applications.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They operate by exerting a constant pressure against the inner surface of a bore or the outer surface of a shaft, thereby securing parts in place. Retaining rings are widely used in various mechanical systems due to their simplicity, reliability, and ease of installation 1.

Purpose of the 4900420 Retaining Ring

The Cummins 4900420 Retaining Ring plays a specific role in the operation of commercial trucks by securing components such as gears, bearings, and other parts within the engine and transmission systems. It ensures that these components remain properly aligned and do not shift during operation, which is vital for the efficient and reliable performance of the truck.

Key Features

The Cummins 4900420 Retaining Ring is characterized by several key features that enhance its functionality. It is typically made from high-strength materials such as spring steel, which provides durability and resistance to wear. The design specifications of the ring, including its diameter and thickness, are tailored to fit specific applications within the truck’s engine and transmission systems. Additionally, the ring may feature unique attributes such as a corrosion-resistant coating to improve longevity in harsh operating environments 2.

Benefits of Using the 4900420 Retaining Ring

Utilizing the Cummins 4900420 Retaining Ring offers several advantages. It contributes to improved reliability by ensuring that critical components remain securely in place, reducing the risk of mechanical failure. Enhanced performance is another benefit, as proper component alignment leads to smoother operation and increased efficiency. Fleet operators may also experience potential cost savings due to the ring’s durability and the reduced need for frequent replacements or repairs.

Installation Process

Proper installation of the Cummins 4900420 Retaining Ring is crucial for its effective function. The process typically involves using specialized tools such as retaining ring pliers to place the ring into the designated groove on the shaft or within the housing. It is important to ensure that the ring is seated correctly and that there is no excessive force applied during installation, which could damage the ring or the surrounding components. Following manufacturer guidelines and best practices will help achieve a secure fit 3.

Troubleshooting Common Issues

Common problems associated with retaining rings include misalignment and wear. Misalignment can occur if the ring is not properly seated during installation, leading to improper component function. Wear may result from prolonged use or exposure to harsh conditions. Troubleshooting steps include inspecting the ring for signs of damage or deformation, ensuring correct installation, and replacing the ring if necessary to maintain system integrity.

Maintenance Tips

Regular maintenance practices can help prolong the lifespan of the Cummins 4900420 Retaining Ring. Inspection intervals should be established based on the truck’s operational conditions and usage. Signs of potential failure, such as unusual noise or vibration, should be investigated promptly. Additionally, keeping the ring and surrounding components clean and free from debris will contribute to its longevity and performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Compatibility with Cummins Engines

The Cummins part 4900420, a Retaining Ring, is designed to be compatible with a range of Cummins engines, specifically the A1400, A1700, A2000, and A2300 models. This retaining ring is a critical component that ensures the proper alignment and function of various parts within these engines.

For the A1400 and A1700 engines, the retaining ring is engineered to fit seamlessly into the specified areas, providing stability and preventing unwanted movement of components. Its precision-engineered design ensures that it meets the stringent requirements of these engines, contributing to their overall efficiency and longevity.

Similarly, for the A2000 and A2300 engines, the retaining ring plays a pivotal role in maintaining the integrity of the engine’s internal mechanisms. The compatibility of this part across these engines underscores its versatility and the importance of using the correct components for optimal engine performance.

Role of Part 4900420 Retaining Ring in Engine Systems

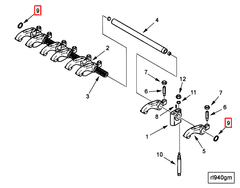

The 4900420 retaining ring is an essential component in ensuring the secure and efficient operation of various engine systems. In the context of engine mechanisms, this retaining ring plays a significant role in the functionality of the lever, rocker, and rocker lever assemblies.

Lever Assemblies

In lever assemblies, the 4900420 retaining ring is employed to hold components in place, preventing them from dislodging during engine operation. This ensures that the lever can transmit motion accurately and consistently, which is vital for the precise control of other engine parts. The retaining ring’s secure fit helps maintain the alignment and integrity of the lever, contributing to the overall stability and performance of the engine.

Rocker Mechanisms

For rocker mechanisms, the 4900420 retaining ring is integral in keeping the rocker arm components properly positioned. The rocker arm is responsible for converting the linear motion of the pushrod into rotational motion for the valve. By securing the rocker arm in place, the retaining ring ensures that the motion transfer is smooth and reliable, which is essential for the efficient opening and closing of engine valves. This, in turn, helps maintain optimal engine performance and fuel efficiency.

Rocker Lever Systems

In rocker lever systems, the 4900420 retaining ring serves a similar purpose by securing the rocker lever components. The rocker lever is a critical part of the valve train, responsible for amplifying the motion from the camshaft to the valve. The retaining ring ensures that all parts of the rocker lever remain in their correct positions, allowing for precise and consistent valve operation. This reliability is key to achieving stable engine operation and preventing potential issues such as valve train noise or misfires.

Conclusion

Overall, the Cummins 4900420 Retaining Ring is a fundamental component in these engine systems, providing the necessary security and stability for the lever, rocker, and rocker lever assemblies to function effectively. Its role in maintaining the integrity and performance of critical engine components underscores its importance in the operation of commercial trucks.

-

P. A. Lakshminarayanan and Avinash Kumar, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer Nature, 2020.

↩ -

Robert Bosch GmbH, Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014.

↩ -

Bruce P. Minaker, Fundamentals of Vehicle Dynamics and Modelling, John Wiley & Sons, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.