This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

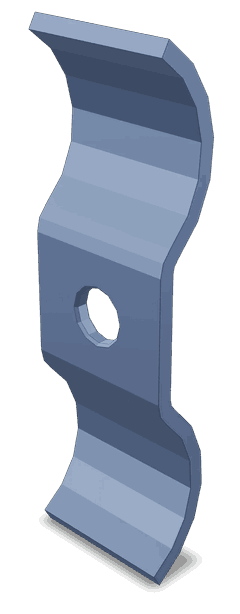

The Cummins 4927607 Retaining Clamp is a critical component in heavy-duty truck maintenance and operation, designed to enhance the efficiency and reliability of the vehicle’s mechanical systems. Understanding its function and importance is essential for maintaining high performance standards in heavy-duty trucking.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices that secure components in place within various systems by applying pressure to prevent movement or separation under operational conditions. In heavy-duty trucks, these clamps ensure the stability and integrity of critical components, contributing to safe and efficient vehicle operation 1.

Purpose of the 4927607 Retaining Clamp

The Cummins 4927607 Retaining Clamp is designed to secure components within the truck’s engine or transmission system. It maintains the alignment and stability of parts, which is vital for the smooth operation of the truck. By securing components, it helps prevent wear, reduce the risk of failure, and contribute to the overall reliability of the truck’s mechanical systems 2.

Key Features

Constructed from durable materials, the 4927607 Retaining Clamp is designed to withstand the rigors of heavy-duty truck operation. Its precise fit and mechanism for applying consistent pressure enhance its functionality, contributing to its effectiveness in maintaining component alignment and stability 3.

Benefits of Using the 4927607 Retaining Clamp

Utilizing the Cummins 4927607 Retaining Clamp offers several advantages, including improved reliability by securely holding components in place, reducing the risk of movement or separation under operational stress. Its design facilitates ease of installation, allowing for quick and efficient replacement or adjustment as needed. Additionally, the clamp’s durability and functionality support maintenance efforts, helping to ensure the longevity and effectiveness of the truck’s mechanical systems.

Installation Process

Installing the Cummins 4927607 Retaining Clamp requires careful attention to ensure a secure fit. The process involves positioning the clamp over the components it is designed to secure, then using the appropriate tools to apply pressure and lock it in place. It is important to follow manufacturer guidelines for installation to ensure the clamp functions as intended and contributes to the reliability of the truck’s mechanical systems.

Troubleshooting Common Issues

Common issues with the 4927607 Retaining Clamp may include improper installation, leading to insufficient pressure or misalignment of components. Addressing these issues involves checking the clamp’s position and ensuring it is correctly installed according to manufacturer specifications. Regular inspections and maintenance can help identify and resolve potential problems, contributing to the clamp’s effectiveness and the truck’s overall performance.

Maintenance Tips

Regular maintenance checks are recommended to ensure the Cummins 4927607 Retaining Clamp remains in good condition and continues to function effectively. This includes inspecting the clamp for signs of wear or damage, ensuring it is securely installed, and replacing it if necessary. Adhering to a maintenance schedule helps to prevent issues and supports the longevity and reliability of the truck’s mechanical systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its products, including the Cummins 4927607 Retaining Clamp, which is designed to meet the demanding requirements of heavy-duty truck operation.

Cummins Retaining Clamp 4927607 Compatibility

The Cummins Retaining Clamp part number 4927607 is designed to fit a variety of Cummins engine models. This part is integral for securing components within the engine assembly, ensuring that parts remain in place and function correctly under operational conditions.

QSK60 Series

- QSK60 CM500: The retaining clamp is used to secure various components within this engine model, ensuring stability and reliability.

- QSK60 CM850 MCRS: This model benefits from the clamp’s ability to maintain the integrity of its components, particularly in high-stress environments.

QSK95 Series

- QSK95 CM2350 K111: The retaining clamp is essential for maintaining the structural integrity of the engine, securing parts that are subject to significant mechanical stress.

- QSK95 CM2350 K113: Similar to the K111 model, this engine utilizes the clamp to ensure that all components are properly secured, contributing to the engine’s overall performance and longevity.

QSV91-G4 Series

- QSV91-G4 CM558/CM700 V102: This model incorporates the retaining clamp to secure components within its complex engine architecture, ensuring that all parts function as intended under various operational conditions.

Each of these engines relies on the retaining clamp to maintain the alignment and stability of critical components, ensuring optimal performance and durability.

Role of Part 4927607 Retaining Clamp in Engine Systems

The Part 4927607 Retaining Clamp is an essential component in the assembly and maintenance of various engine systems, ensuring the secure attachment and stability of multiple parts. Its application spans across several key systems, enhancing their functionality and reliability.

Auxiliary Cooling System

In the auxiliary cooling system, the Retaining Clamp 4927607 is utilized to secure plumbing connections. This ensures that coolant flows efficiently through the system without leaks, maintaining optimal engine temperature and preventing overheating. The clamp’s reliable hold is vital for the consistent performance of the cooling system, especially under varying operational conditions.

Aftercooler Water Plumbing

For the aftercooler water plumbing, the Retaining Clamp 4927607 plays a significant role in securing the connections between the aftercooler and the water supply lines. This setup is crucial for the effective cooling of compressed air from the turbocharger, which in turn enhances engine efficiency and reduces the risk of component wear. The clamp ensures that the water lines remain intact, providing a steady flow of cooling water to the aftercooler.

Turbocharger System

Within the turbocharger system, the Retaining Clamp 4927607 is employed to secure various plumbing connections, including those for the lubrication and cooling systems. This ensures that the turbocharger operates within its designed parameters, enhancing its longevity and performance. The clamp’s ability to maintain a secure connection under high pressure and temperature conditions is particularly beneficial in this application.

General System Integration

Across these systems, the Retaining Clamp 4927607 contributes to the overall integrity and reliability of the engine. By ensuring that plumbing connections remain secure, it prevents leaks and maintains the efficiency of fluid flow throughout the engine. This not only enhances the performance of individual components but also contributes to the engine’s overall durability and operational stability.

Conclusion

The Cummins 4927607 Retaining Clamp plays a vital role in the maintenance and operation of heavy-duty trucks by securing critical components within the engine and transmission systems. Its durable construction, precise fit, and consistent pressure application contribute to the reliability and efficiency of the truck’s mechanical systems. Regular maintenance and proper installation are key to ensuring the clamp’s effectiveness and the truck’s overall performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.