This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

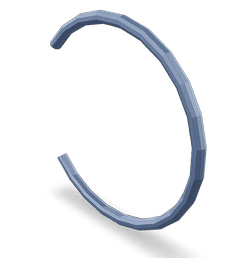

The 5311011 Retaining Ring, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, produces this retaining ring to meet the demanding requirements of heavy-duty applications. This part is integral to ensuring the secure operation of various truck components, contributing to the overall efficiency and reliability of commercial vehicles.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They function by exerting a radial force that keeps parts in place, ensuring that they do not dislodge under operational stress. Retaining rings are commonly used in a variety of mechanical systems to secure bearings, gears, and other components, playing a vital role in maintaining the integrity and functionality of these systems 1.

Purpose of the 5311011 Retaining Ring

The 5311011 Retaining Ring is specifically designed to secure components within the commercial truck’s drivetrain and transmission systems. It ensures that parts such as gears and bearings remain in their designated positions, which is crucial for the smooth operation of the truck. By maintaining the proper alignment and positioning of these components, the retaining ring contributes to the overall performance and durability of the truck’s mechanical systems 2.

Key Features

The 5311011 Retaining Ring is engineered with specific design and material characteristics to meet the rigorous demands of commercial truck applications. It is typically made from high-strength steel, which provides excellent durability and resistance to wear. The ring’s design allows for easy installation and removal, ensuring that maintenance procedures are efficient and straightforward. Additionally, its precise dimensions and tolerances ensure a secure fit, minimizing the risk of component displacement 3.

Benefits

Using the 5311011 Retaining Ring offers several advantages. It enhances the reliability of the secured components by ensuring they remain in place under operational stress. This reduces the likelihood of component failure and extends the lifespan of the truck’s mechanical systems. Additionally, the retaining ring contributes to overall system efficiency by maintaining proper alignment and reducing friction, which can lead to improved fuel economy and performance. Furthermore, its design reduces maintenance requirements, as it is less prone to wear and displacement compared to other fastening methods.

Installation Process

Installing the 5311011 Retaining Ring requires careful attention to ensure proper fitting. The process involves using appropriate tools, such as retaining ring pliers, to expand the ring and place it over the shaft or within the housing. It is important to ensure that the ring is seated correctly and that there is no excessive force applied during installation, as this could damage the ring or the surrounding components. Following the manufacturer’s guidelines and best practices will help ensure a secure and effective installation.

Troubleshooting Common Issues

Common issues with retaining rings include displacement or damage, which can lead to component failure. If a retaining ring becomes dislodged, it should be replaced immediately to prevent further problems. Inspecting the ring for signs of wear, such as cracks or deformation, is also important. If any damage is detected, the ring should be replaced to maintain the integrity of the mechanical system. Regular maintenance and inspection can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

Regular inspection and maintenance of the 5311011 Retaining Ring are crucial for ensuring continued reliable performance. Inspect the ring during routine maintenance checks for signs of wear, such as cracks, deformation, or corrosion. Ensure that the ring remains properly seated and that there are no signs of displacement. Following these maintenance practices will help prolong the life of the retaining ring and the components it secures, contributing to the overall reliability of the truck’s mechanical systems.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry. Founded in 1919, Cummins has built a legacy of innovation and quality, producing a wide range of automotive components, including engines, transmissions, and aftermarket parts. The company is committed to delivering high-quality products that meet the demanding requirements of commercial and industrial applications. Cummins’ dedication to research and development ensures that their components, such as the 5311011 Retaining Ring, are designed to provide reliable performance and durability in heavy-duty environments.

Cummins Retaining Ring 5311011 Compatibility with Various Engines

The Cummins Retaining Ring part number 5311011 is designed to fit a variety of engine models. Here is a detailed breakdown of its compatibility across different engine types:

F2.8 CM2620 F135B

The retaining ring is compatible with the F2.8 CM2620 F135B engine, ensuring secure placement and functionality of various components.

ISF2.8 CM2220 Series

The part number 5311011 is suitable for the following ISF2.8 CM2220 engines:

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

These engines benefit from the retaining ring’s ability to maintain the integrity of their internal components.

QSF2.8 CM2880 Series

The retaining ring is also compatible with the following QSF2.8 CM2880 engines:

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F108

- QSF2.8 CM2880 F114

This series of engines relies on the retaining ring to ensure that parts remain in their designated positions, contributing to the overall efficiency and reliability of the engine.

R2.8 CM2220 R101B

The retaining ring is also compatible with the R2.8 CM2220 R101B engine, providing essential support and security for its components.

Each of these engines, despite their unique specifications, shares a common requirement for the retaining ring to maintain operational integrity. The compatibility of the Cummins Retaining Ring 5311011 across these engines underscores its versatility and importance in ensuring the smooth functioning of the engine systems.

Role of Part 5311011 Retaining Ring in Engine Systems

The 5311011 retaining ring is an essential component in various engine systems, ensuring the secure assembly and operation of several key elements.

In an engine piston kit, the retaining ring plays a significant role by securing the piston within the cylinder. This ensures that the piston remains in its correct position during the engine’s operation, thereby maintaining the integrity of the combustion process. The ring prevents the piston from shifting or dislodging, which could lead to engine malfunction or failure.

When considering the piston itself, the retaining ring is instrumental in keeping the piston pin (or wrist pin) in place. This is vital for the piston’s reciprocating motion, which is fundamental to the engine’s function. The ring ensures that the piston pin does not move out of alignment, thus preserving the smooth operation of the engine.

In the broader context of the engine, the retaining ring contributes to the overall reliability and performance. By securing components in their designated positions, it helps maintain the precise engineering tolerances required for optimal engine efficiency. This, in turn, supports consistent power delivery and reduces the likelihood of mechanical issues arising from component misalignment.

Conclusion

The 5311011 Retaining Ring by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its design and material characteristics ensure durability and reliability in heavy-duty applications. Proper installation, regular maintenance, and timely replacement of worn or damaged rings are essential practices to ensure the continued efficiency and reliability of the truck’s mechanical systems. Cummins’ commitment to quality and innovation is evident in the design and functionality of this part, making it a valuable asset in the automotive industry.

-

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles (SAE International, 2014).

↩ -

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning (Jones Bartlett Learning, 2018).

↩ -

Konrad Reif Ed, Brakes Brake Control and Driver Assistance Systems Function Regulation and Components (Springer, 2014).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.