This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

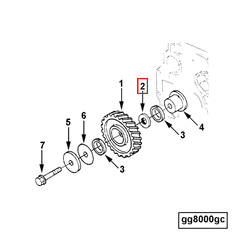

The C0406505520 Retaining Ring, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts that contribute to the efficiency and reliability of truck operations. Retaining rings, in general, play a role in mechanical systems by securing components in place, ensuring that parts remain correctly positioned and function as intended 1.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They are typically made from spring steel and come in various shapes and sizes to accommodate different applications. The primary function of a retaining ring is to secure parts in place without the need for additional fasteners, which can simplify assembly and disassembly processes 2.

Purpose of the C0406505520 Retaining Ring

The C0406505520 Retaining Ring is specifically designed to secure components within the truck’s mechanical systems. It ensures that parts such as gears, bearings, and other rotating components remain in their designated positions. By doing so, it contributes to the smooth operation of the truck, helping to maintain alignment and prevent unwanted movement that could lead to wear or failure 3.

Key Features

The C0406505520 Retaining Ring is characterized by its precise design and material composition. It is typically made from high-quality steel, which provides the necessary strength and durability for its application. The ring’s shape and size are tailored to fit specific components, ensuring a secure fit. Additionally, it may feature specialized ends or a particular cross-section to enhance its functionality and ease of installation 4.

Benefits of Using the C0406505520 Retaining Ring

Utilizing the C0406505520 Retaining Ring offers several advantages. It contributes to the reliability of the truck’s mechanical systems by securely holding components in place. The design of the ring allows for straightforward installation and removal, which can save time during maintenance procedures. Furthermore, its durable construction ensures long-term performance, reducing the need for frequent replacements 1.

Installation Process

Installing the C0406505520 Retaining Ring requires careful attention to ensure proper placement and function. The process typically involves using a retaining ring plier to expand the ring and position it around the component. Once in place, the ring should be checked for secure fitment and correct orientation. It is important to follow manufacturer guidelines to ensure the ring is installed correctly 2.

Troubleshooting Common Issues

Common issues with retaining rings may include displacement or damage. If a retaining ring becomes dislodged, it should be carefully removed and replaced with a new one to ensure the component remains secure. Damage to the ring may require replacement to maintain the integrity of the mechanical system. Regular inspections can help identify potential issues before they lead to more significant problems 3.

Maintenance Tips

To ensure the continued optimal performance of the C0406505520 Retaining Ring, regular inspections are recommended. Checking for signs of wear, damage, or displacement can help identify issues early. Additionally, ensuring that the ring is correctly installed and that the components it secures are in good condition will contribute to the overall reliability of the truck’s mechanical systems 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for truck manufacturers and operators worldwide 1.

Role of Part C0406505520 Retaining Ring in Engine Systems

The C0406505520 Retaining Ring is an essential component in various engine systems, ensuring the secure placement and operation of multiple parts.

Accessory Drive System

In the accessory drive system, the retaining ring plays a significant role in maintaining the alignment and stability of the driven components. It secures the accessory drive pulleys and sprockets, preventing them from dislodging or shifting during operation. This ensures consistent power transmission to accessories such as the alternator, power steering pump, and air conditioning compressor 2.

Housing Assemblies

Within the housing assemblies, the retaining ring is utilized to hold various internal components in place. It ensures that gears, bearings, and other moving parts remain correctly positioned, which is vital for the smooth operation and longevity of the housing unit. This is particularly important in environments where the housing is subject to vibrations and high-stress conditions 3.

Front Gear System

In the front gear system, the retaining ring is instrumental in securing the front gear to the shaft or housing. This prevents any axial movement that could lead to gear misalignment, excessive wear, or failure. The retaining ring ensures that the front gear operates within its designed parameters, contributing to the overall efficiency and reliability of the engine system 4.

Conclusion

The C0406505520 Retaining Ring is a critical component in the maintenance and operation of commercial truck engines. Its role in securing various components within the engine systems ensures the smooth and reliable operation of the truck. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Bosch Fuel Injection Systems, Forbes Aird, HP Books, 2001

↩ ↩ ↩ -

Design of Racing and High-Performance Engines 2004-2013, Douglas R. Fehan, SAE International, 2013

↩ ↩ ↩ -

Simulation and Optimization of Internal Combustion Engines, Zhiyu Han, SAE International, 2022

↩ ↩ ↩ -

Diesel Mechanics, First Edition, Frank Sander, Global Media, 2007

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.