This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

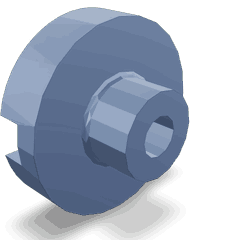

The Cummins 3200934 Retainer Plug is a vital component in commercial trucks, designed to enhance the efficiency and reliability of the vehicle’s engine or transmission system. Understanding its function and importance is essential for maintaining optimal truck performance.

Basic Concepts of Retainer Plugs

Retainer plugs are mechanical devices that seal openings in various systems, preventing fluid or gas escape. In truck engines or transmissions, they maintain pressure within specified parameters and protect components from contaminants or damage. The operation involves inserting the plug into a designated port and securing it to create a barrier crucial for system integrity 1.

Purpose of the 3200934 Retainer Plug

This Cummins part provides a seal in specific areas of the engine or transmission, managing pressure and protecting components from damage. By ensuring fluids and gases remain within the system, it contributes to the smooth and efficient operation of the truck 2.

Key Features

The 3200934 Retainer Plug is made from durable materials to withstand high pressures and temperatures. Its design includes precise dimensions for a snug fit and may feature anti-rotation attributes to prevent loosening over time 3.

Benefits

Using this part offers benefits such as improved system efficiency through proper pressure maintenance and leak prevention. It enhances the longevity of connected components by protecting them from contaminants and excessive wear, increasing the reliability of the truck’s operation 4.

Installation Process

Installing the 3200934 Retainer Plug requires cleaning the port, inserting the plug, and securing it with tools like torque wrenches. Best practices include verifying the plug’s position and seal after installation to ensure proper function 5.

Troubleshooting Common Issues

Common issues with retainer plugs include leaks or malfunctions due to wear or improper installation. Troubleshooting involves inspecting the plug for damage, checking the seal, and ensuring correct installation. Replacement or re-seating may be necessary if issues are detected 6.

Maintenance Tips

Regular maintenance of the 3200934 Retainer Plug is crucial for its effective operation. This includes periodic inspection for wear or damage, cleaning the plug and port, and replacing the plug if it shows signs of failure. Adhering to manufacturer-recommended inspection intervals ensures the plug remains in good working condition 7.

Role in Engine and Transmission Systems

The 3200934 Retainer Plug interacts with other components within the engine and transmission systems by providing a necessary seal that contributes to the systems’ performance and durability. Its role in pressure management and component protection is integral to the efficient operation of these complex systems 8.

Cummins Retainer Plug 3200934 Compatibility

The Cummins Retainer Plug 3200934 is compatible with various engine models, including K19, KTA19GC, KTA19GC CM558, QSK19 CM500, and QSK19G. It ensures optimal performance and reliability by providing a secure seal, which is crucial for the engine’s operational safety and longevity 9.

Integration with Base Parts and Kits

In the assembly of base parts and kits, the Retainer Plug ensures components are correctly aligned and secured, essential for the efficient operation of the engine 10.

Onboard Spares

For onboard spares, the Retainer Plug stores and secures additional components needed for repairs or replacements during operation, ensuring essential components are readily available 11.

Lubricating Oil Pump

In the lubricating oil pump system, the Retainer Plug maintains the integrity of the pump by securing internal components, vital for the consistent flow of lubricating oil and reducing friction and wear on moving parts within the engine 12.

General Parts and Base

Across various general parts and the engine base, the Retainer Plug ensures components remain fixed in place, important for the structural integrity of the engine and the precise operation of moving parts 13.

Pump and Lubricating Oil Systems

Within pump and lubricating oil systems, the Retainer Plug maintains the correct positioning of components, essential for the efficient circulation of lubricating oil, protecting the engine from excessive wear and damage, and ensuring longer operational life and reliability 14.

Conclusion

The 3200934 Retainer Plug is a versatile component that enhances the functionality and reliability of various engine systems by securely holding components in place. Its role in pressure management, component protection, and system efficiency is integral to the overall performance and durability of commercial trucks.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Berns, K., et al. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Berns, K., et al. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Berns, K., et al. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.