This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3821725 Retainer Plug is a component designed for use in commercial truck engine systems. Its primary role is to secure and maintain the integrity of various engine components, ensuring they function correctly under operational conditions. This part is integral to the overall performance and reliability of the truck’s engine.

Purpose and Function

The Cummins 3821725 Retainer Plug serves to hold specific engine components in place, preventing them from dislodging or moving during engine operation. It operates by fitting into designated slots or openings within the engine assembly, providing a secure fit that withstands the vibrations and pressures encountered during truck operation. This function is vital for maintaining the alignment and operational efficiency of the engine’s moving parts 1.

Key Features

This Cummins part is constructed from durable materials, ensuring it can withstand the harsh conditions within a truck engine. Its design includes precise dimensions and a secure fitting mechanism, which allows it to effectively hold components in place. Additionally, the plug may feature unique characteristics such as anti-corrosive coatings or specialized shapes to enhance its performance and longevity in the engine environment 2.

Benefits

Utilizing the Cummins 3821725 Retainer Plug offers several advantages. It contributes to improved engine efficiency by ensuring components remain in their correct positions, reducing the risk of mechanical failures. The plug’s durable construction and secure fit enhance the engine’s overall reliability and durability, potentially leading to longer engine life and reduced maintenance needs 3.

Installation Process

Installing the Cummins 3821725 Retainer Plug requires careful attention to ensure it is correctly positioned and securely fitted. The process involves identifying the correct slot or opening within the engine assembly, inserting the plug, and verifying its secure fit. Tools such as torque wrenches may be required to ensure the plug is properly installed without over-tightening, which could damage the component or the engine assembly.

Common Issues and Troubleshooting

Typical problems associated with Retainer Plugs include improper fitting, which can lead to component misalignment or engine inefficiencies. Troubleshooting steps may involve re-evaluating the plug’s fit, ensuring it is correctly aligned and securely in place. In cases where the plug shows signs of wear or damage, replacement may be necessary to restore engine performance.

Maintenance Tips

Regular maintenance of the Cummins 3821725 Retainer Plug involves periodic inspection for signs of wear, corrosion, or damage. Ensuring the plug remains securely fitted and in good condition can help maintain engine efficiency and reliability. Cleaning the area around the plug and applying protective coatings, if recommended, can also contribute to its longevity.

Compatibility and Usage

The Cummins 3821725 Retainer Plug is designed for use in specific engine types and truck models. Its application is tailored to meet the requirements of these engines, ensuring compatibility and optimal performance. Users should consult engine specifications or manufacturer guidelines to confirm compatibility with their specific truck model.

Manufacturer Information

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of engine and component products. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance engine parts. The company’s commitment to excellence is reflected in its product offerings, including the Cummins 3821725 Retainer Plug.

Compatibility of Retainer Plug Part 3821725 with Cummins Engines

The Retainer Plug part 3821725, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the engine’s operation, ensuring proper sealing and functionality. Below is a detailed description of its compatibility with specific Cummins engine models:

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

The Retainer Plug part 3821725 is compatible with the ISM series engines, including the ISM CM570, ISM CM570/870, ISM CM876, and ISM11 CM876 SN. This plug is essential for maintaining the integrity of the engine’s internal components by providing a secure seal.

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The Retainer Plug part 3821725 also fits the L10 series engines, which include the L10 CELECT, L10 GAS, and L10 MECHANICAL models. This part ensures that the engine operates efficiently by preventing leaks and maintaining pressure within the system.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

For the M11 series engines, the Retainer Plug part 3821725 is compatible with the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL models. This plug is crucial for the proper functioning of these engines, ensuring that all components are securely sealed.

QSM11 Series Engines

- QSM11 CM570

- QSM11 CM876

Lastly, the Retainer Plug part 3821725 is also suitable for the QSM11 series engines, including the QSM11 CM570 and QSM11 CM876. This part plays a vital role in maintaining the engine’s performance by providing a reliable seal.

Role of Part 3821725 Retainer Plug in Engine Systems

The Part 3821725 Retainer Plug is an essential component in maintaining the integrity and functionality of various engine systems. Its primary role is to secure and retain other components within the engine, ensuring they remain in place and function correctly under operational conditions.

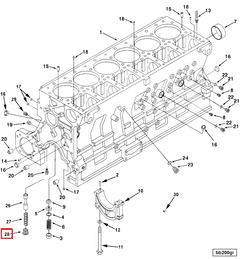

Integration with the Cylinder Block

In the cylinder block, the Retainer Plug is used to secure components such as the plug and spring assembly. This assembly is vital for maintaining pressure and ensuring the smooth operation of the pistons within the cylinders. The Retainer Plug helps prevent the displacement of these components, which could lead to inefficiencies or damage within the engine.

Function in the Lubricating Oil Pump

The lubricating oil pump relies on the Retainer Plug to keep its internal components aligned and secured. This is particularly important for the consistent flow of lubricating oil throughout the engine. The Retainer Plug ensures that the pump’s parts, such as valves and springs, remain in their correct positions, allowing for uninterrupted oil circulation which is essential for reducing friction and wear on moving parts.

Role in the Plumbing System

Within the engine’s plumbing system, the Retainer Plug is used to secure fittings and connections. This is important for maintaining the integrity of the oil and coolant pathways. By ensuring that these connections remain tight and secure, the Retainer Plug helps prevent leaks and maintains the proper flow of fluids, which is essential for engine cooling and lubrication.

Contribution to the Engine Block Kit

In an engine block kit, the Retainer Plug is often included to facilitate the reassembly of the engine. It ensures that all components are correctly positioned and secured, which is vital for the engine’s performance and longevity. The Retainer Plug plays a key role in the successful installation and operation of the engine block kit by maintaining the structural integrity of the assembly.

Overall Engine Functionality

Across the engine, the Retainer Plug contributes to the overall functionality by ensuring that critical components remain in place. This is particularly important in high-stress environments where vibrations and operational forces could otherwise dislodge parts. The Retainer Plug’s role in securing these components helps maintain engine efficiency, reliability, and safety.

Conclusion

The Cummins 3821725 Retainer Plug is a critical component in the maintenance and operation of commercial truck engines. Its role in securing engine components, ensuring proper alignment, and contributing to overall engine efficiency and reliability cannot be overstated. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.