This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3930910 Retainer Plug is a component designed for use in commercial trucks. It serves a specific function within the truck’s system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is fundamental for maintaining the operational integrity of commercial trucks.

Function and Operation

The Cummins 3930910 Retainer Plug operates by sealing specific points within the truck’s system, thereby maintaining system integrity and preventing leaks. Its placement in the system is strategic, ensuring that fluids and gases remain contained within their designated pathways. This containment is vital for the consistent performance of the truck’s engine and other mechanical systems 1.

Purpose of the Retainer Plug

The Retainer Plug plays a role in the operation of a truck by sealing and protecting various components from external contaminants and internal leaks. Its design allows it to fit securely in place, providing a barrier that is crucial for the protection of sensitive parts within the engine and transmission systems 2.

Key Features

The Cummins 3930910 Retainer Plug is constructed from durable materials, ensuring it can withstand the harsh conditions present in commercial truck environments. Its design includes features that enhance its sealing capabilities, such as a precise fit and robust material composition. These characteristics contribute to its effectiveness in preventing leaks and protecting the system from contaminants 3.

Benefits

Incorporating the Cummins 3930910 Retainer Plug into a truck’s system offers several advantages. It contributes to improved system reliability by ensuring that seals remain intact under various operating conditions. Additionally, it reduces the need for frequent maintenance by minimizing the risk of leaks and contamination. The overall performance of the truck is enhanced, as the Retainer Plug helps maintain the integrity of the system it protects.

Installation Process

Proper installation of the Cummins 3930910 Retainer Plug is crucial for its effectiveness. The process involves ensuring the plug is correctly aligned and securely fitted in its designated location. Tools may be required to achieve a proper fit, and following manufacturer guidelines is recommended to ensure the plug functions as intended.

Troubleshooting Common Issues

Common issues with Retainer Plugs may include leaks or difficulty in installation. Troubleshooting these problems involves inspecting the plug for signs of wear or damage and ensuring it is correctly installed. Addressing these issues promptly can prevent more significant problems within the truck’s system.

Maintenance Tips

Regular maintenance of the Cummins 3930910 Retainer Plug is recommended to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear or damage and replacement according to manufacturer guidelines. Adhering to these practices helps maintain the integrity of the truck’s system.

Manufacturer Overview - Cummins

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and commitment to quality. The company’s history of innovation and reliability is reflected in its products, including the 3930910 Retainer Plug. Cummins’ reputation for producing high-quality components underscores the reliability and performance of this Retainer Plug in commercial truck applications.

Cummins Engine Part 3930910: Retainer Plug Compatibility

The Cummins part 3930910, a Retainer Plug, is designed to fit a variety of Cummins engines. This part is integral to the engine’s operation, ensuring that certain components remain securely in place. Below is a detailed breakdown of the engines with which this part is compatible:

6C8.3 Series

- 6C8.3

- 6C8.3 CM556

C8.3 Series

- C8.3 G

- C8.3 CM556

G8.3 Series

- G8.3

- G8.3 CM558

- GTA8.3 CM558

ISC Series

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

ISL Series

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

L Series

- L GAS PLUS CM556

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L8.9G CMOH2.0 L125B

- L9 CM2670 L128B

- L9.3 L105

- L9.5 L117

QSC8.3 Series

- QSC8.3 CM2880 C102

The Retainer Plug 3930910 is engineered to fit seamlessly into these engines, ensuring that it performs its function effectively across the different engine series. This compatibility highlights the versatility and robustness of the part, making it a reliable choice for maintenance and repairs across a wide range of Cummins engines.

Understanding the Role of Part 3930910 Retainer Plug in Engine Systems

The Retainer Plug, identified by part number 3930910, serves a significant function within various engine systems. Its primary role is to maintain the integrity and efficiency of the oil management system by securing components in place and ensuring proper oil flow.

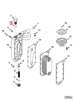

Integration with the Oil Filter System

In the context of the oil filter cooler and lubricating oil filter head, the Retainer Plug is essential for securing these components. It ensures that the oil filter remains properly seated, preventing oil leaks and maintaining efficient filtration. This is particularly important in high-performance engines where clean oil is vital for engine longevity and performance.

Role in the Lubricating System

When considering the lubricating oil filter kit, the Retainer Plug helps in the assembly process by holding the filter in position. This ensures that the filter can perform its duty of removing contaminants from the oil, thereby protecting engine components from wear and tear.

Contribution to the Engine Oil Cooler

In the engine oil cooler system, the Retainer Plug plays a part in maintaining the structural integrity of the cooler. By securing the cooler in place, it ensures that the oil is effectively cooled before it circulates back into the engine, which is crucial for maintaining optimal engine temperature and performance.

Importance in the Long Block Assembly

Within the long block—comprising the engine block, crankshaft, pistons, and other essential components—the Retainer Plug aids in the secure fitting of various oil management components. This ensures that the long block operates efficiently, with minimal risk of oil leaks or component misalignment.

Supporting the Mounting Kit

The mounting kit often includes the Retainer Plug to ensure that oil filter assemblies are correctly installed and secured. This is important for the overall stability and functionality of the engine’s oil system, ensuring that all components work in harmony.

Enhancing the Engine Head

In the engine head, the Retainer Plug assists in securing oil passages and filter components, ensuring that oil distribution is consistent and reliable. This contributes to the engine head’s ability to maintain proper lubrication of critical components, enhancing overall engine performance and reliability.

By understanding the role of the Retainer Plug in these various engine systems, engineers and mechanics can better appreciate its importance in maintaining the efficiency and reliability of the engine’s oil management system.

Conclusion

The Cummins 3930910 Retainer Plug is a critical component in the maintenance and operation of commercial trucks. Its role in sealing and protecting various engine components, ensuring system integrity, and enhancing overall performance cannot be overstated. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engines are essential for maximizing the benefits of this part. Cummins’ reputation for quality and innovation is reflected in the design and functionality of the 3930910 Retainer Plug, making it a reliable choice for professionals in the commercial truck industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.