3177367

Retaining Clamp

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

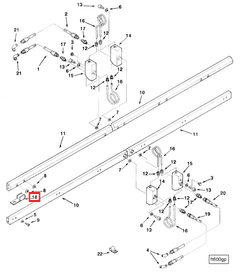

The 3177367 Retaining Clamp, a component manufactured by Cummins, is designed for use in commercial trucks. This part plays a role in securing various parts and ensuring the smooth operation of the vehicle. Retaining clamps are integral to heavy-duty truck operations, providing stability and security to components that are subject to vibration and movement 1.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold parts in place. They function by applying pressure to secure components, preventing them from moving or vibrating loose. In mechanical systems, retaining clamps contribute to the integrity and performance of various components by ensuring they remain in the correct position and operate as intended 2.

Purpose of the 3177367 Retaining Clamp

The 3177367 Retaining Clamp is specifically designed to secure parts within a truck’s system. It finds application in areas where components are prone to movement due to the truck’s operation. By holding these parts firmly in place, the clamp supports the efficient functioning of the truck’s systems, contributing to overall vehicle performance and safety.

Key Features

The 3177367 Retaining Clamp boasts several features that enhance its functionality. It is constructed from durable materials, ensuring longevity and resistance to the harsh conditions encountered in commercial truck operations. Its design includes attributes that allow for easy installation and adjustment, making it a versatile component for various applications.

Benefits

Utilizing the 3177367 Retaining Clamp offers several advantages. It contributes to improved safety by securing components that could otherwise become loose and cause damage. Enhanced performance is another benefit, as the clamp ensures parts remain in their intended positions, allowing systems to operate efficiently. Reliability is also increased, as the clamp’s durable construction and secure hold reduce the likelihood of component failure.

Installation Process

Installing the 3177367 Retaining Clamp requires following a series of steps to ensure it is properly secured. The process involves identifying the correct location for the clamp, using the appropriate tools to install it, and adjusting it to achieve the desired level of pressure. Best practices include checking the clamp periodically to ensure it remains secure and functions as intended.

Troubleshooting Common Issues

Common problems with retaining clamps can include loosening over time or damage due to wear and tear. Identifying these issues early is important for maintaining the integrity of the truck’s systems. Solutions may involve tightening the clamp, replacing worn parts, or addressing underlying causes such as excessive vibration.

Maintenance Tips

Regular maintenance of the 3177367 Retaining Clamp is key to its longevity and effectiveness. This includes routine inspections to check for signs of wear or damage, cleaning the clamp to remove any debris that could affect its performance, and considering replacement if it shows significant signs of wear or if it no longer secures components effectively.

Cummins: A Brief Overview

Cummins Inc. is a leader in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a reputation for reliability and performance. The company’s history is marked by a dedication to advancing technology and meeting the needs of its customers in the commercial trucking sector 3.

Cummins Retaining Clamp Part 3177367 Compatibility

The Cummins Retaining Clamp part number 3177367 is designed to be compatible with a range of Cummins engines, ensuring secure fastening and stability in various applications. This part is crucial for maintaining the integrity of engine components by preventing unwanted movement and ensuring that parts remain in their designated positions.

K38 Engine Series

For the K38 engine series, the retaining clamp part 3177367 is engineered to fit seamlessly with the engine’s design. It is used in areas where secure fastening is critical, such as securing hoses, brackets, and other engine accessories. The clamp’s robust construction and precise fit ensure that it can withstand the operational stresses of the engine, providing long-lasting performance and reliability.

K50 Engine Series

Similarly, in the K50 engine series, the retaining clamp part 3177367 plays a vital role in maintaining the engine’s structural integrity. This part is specifically designed to fit the unique requirements of the K50 engines, ensuring that all fastened components remain securely in place. The clamp’s design allows for easy installation and removal, making it a convenient choice for maintenance and repairs.

Grouping of Engines

The retaining clamp part 3177367 is particularly beneficial when used across multiple engines within the same series. By using a standardized part, maintenance and repair processes can be streamlined, reducing the need for multiple specialized parts. This not only simplifies inventory management but also ensures that the correct part is used for each application, enhancing overall engine performance and longevity.

The compatibility of the retaining clamp part 3177367 with both the K38 and K50 engine series underscores its versatility and importance in maintaining engine stability and efficiency.

Understanding the Role of Part 3177367 Retaining Clamp in Engine Systems

The Part 3177367 Retaining Clamp is an essential component in various engine systems, ensuring the secure and efficient operation of several key elements. This clamp is instrumental in maintaining the integrity and performance of the following components:

Fuel System Components

-

Fuel Left Bank Manifold and Fuel Right Bank Manifold: The retaining clamp secures these manifolds, ensuring a tight seal that prevents fuel leaks and maintains consistent fuel pressure. This is vital for the efficient operation of the fuel injection system.

-

Fuel Manifold: By clamping the fuel manifold, it ensures that the fuel distribution to the injectors is uniform, which is essential for balanced engine performance.

-

Fuel Pump Conversion Kit: The clamp is used to secure connections within the fuel pump conversion kit, ensuring that the fuel lines are properly sealed and that the fuel pump operates within its designed parameters.

Oil System Components

- Oil Transfer L B Connection: This clamp is critical in securing the oil transfer lines, ensuring that oil flows smoothly between the engine components without leaks, which is essential for lubrication and cooling.

Performance and Plumbing Components

-

Base Parts and Performance Parts: The retaining clamp is often used to secure base parts and performance parts, ensuring that these components remain firmly in place under the stress of engine operation.

-

Plumbing Injector: Securely clamping the plumbing injector ensures that fuel is delivered precisely and consistently to the engine cylinders, enhancing overall engine performance.

Additional Applications

- Step White Smoke Kit: The clamp is also utilized in kits designed to address white smoke issues, ensuring that all connections are secure and that the kit functions as intended to reduce emissions and improve engine efficiency.

Conclusion

In summary, the Part 3177367 Retaining Clamp plays a significant role in maintaining the secure and efficient operation of various engine components, from fuel and oil systems to performance enhancements and emission control kits. Its compatibility with Cummins engines, ease of installation, and durable construction make it a valuable component in the maintenance and operation of commercial trucks.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.