This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

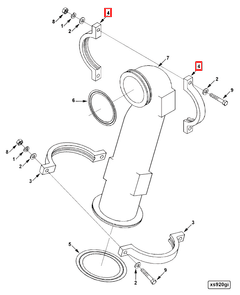

The 3352492 Retaining Clamp, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part is one such component, playing a role in ensuring the secure attachment of various parts within the truck’s system 1.

Function and Operation

This part operates by providing a secure hold for components within the truck’s system. It employs mechanical principles to create a firm grip, ensuring that parts remain in place under various operating conditions. The clamp interacts with other components by fitting around them and applying consistent pressure, which helps in maintaining the integrity of the connections 2.

Purpose of the 3352492 Retaining Clamp

The primary role of the 3352492 Retaining Clamp in truck operations is to maintain the secure attachment of components, which is vital for the system’s integrity and efficiency. By ensuring that parts remain firmly in place, the clamp contributes to the overall reliability of the truck’s system, reducing the likelihood of detachment or misalignment that could lead to operational issues 3.

Key Features

The 3352492 Retaining Clamp is characterized by several key features that enhance its performance. It is constructed from durable materials, designed to withstand the rigors of commercial truck use. The clamp’s design includes elements that allow for easy installation and adjustment, ensuring a secure fit around various components. Additionally, it may feature unique characteristics such as corrosion resistance or temperature tolerance, further contributing to its effectiveness in demanding environments.

Benefits

The advantages of using the 3352492 Retaining Clamp include improved reliability and durability of the truck’s system. Its secure hold on components reduces the risk of detachment, which can lead to operational disruptions. Additionally, the clamp’s durability can contribute to cost savings for fleet operators by reducing the need for frequent replacements or repairs.

Installation Process

Installing the 3352492 Retaining Clamp involves several steps to ensure proper fit and function. Begin by identifying the component that requires securing. Position the clamp around the component, ensuring it is aligned correctly. Apply even pressure to the clamp to create a secure hold. It is important to follow manufacturer guidelines for torque specifications and to use the appropriate tools to avoid damage to the clamp or component.

Common Issues and Troubleshooting

Typical problems with the 3352492 Retaining Clamp may include improper fit, damage from wear, or corrosion. To address these issues, first, ensure that the clamp is correctly aligned and applied with the appropriate pressure. If damage is present, assess whether the clamp can be repaired or if replacement is necessary. Corrosion can often be mitigated by using clamps with corrosion-resistant properties or by applying protective coatings.

Maintenance Tips

Regular maintenance of the 3352492 Retaining Clamp is important for ensuring its longevity and optimal performance. Inspect the clamp periodically for signs of wear, corrosion, or damage. Clean the clamp and its surrounding area to remove any debris that could affect its grip. Lubricate moving parts if applicable, and ensure that the clamp remains securely in place. Following these practices can help maintain the effectiveness of the clamp over time.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses. Cummins’ commitment to excellence is reflected in its extensive product line and the trust it has earned among fleet operators and manufacturers worldwide.

Cummins Retaining Clamp 3352492 Compatibility

The Cummins Retaining Clamp part number 3352492 is a versatile component designed to fit a range of Cummins engines. This retaining clamp is essential for securing various parts within the engine, ensuring they remain in place during operation. Here is how it fits with the specified engines:

-

6C8.3: The 3352492 retaining clamp is compatible with the 6C8.3 engine, providing a secure hold for critical components, ensuring operational integrity and longevity.

-

ISC CM850: This retaining clamp is engineered to fit the ISC CM850 engine, offering reliable retention for parts that require precise positioning.

-

ISL9 CM2150 SN and ISL9.5 CM2880 L138: Both the ISL9 CM2150 SN and ISL9.5 CM2880 L138 engines benefit from the 3352492 retaining clamp. It ensures that components are held firmly in place, contributing to the overall stability and performance of these engines.

-

L8.9: The L8.9 engine also utilizes the 3352492 retaining clamp. This part is crucial for maintaining the structural integrity of the engine by securing various parts effectively.

The compatibility of the 3352492 retaining clamp across these engines highlights its importance in maintaining engine performance and reliability.

Role of Part 3352492 Retaining Clamp in Engine Systems

The Part 3352492 Retaining Clamp is an essential component in maintaining the integrity and efficiency of various engine systems. Its primary function is to secure and stabilize connections, ensuring that components remain firmly in place under operational conditions.

Connection Stability

In engine systems, secure connections are paramount to prevent leaks and ensure optimal performance. The Retaining Clamp plays a significant role in stabilizing connections between different engine components. By providing a tight and consistent grip, it prevents loosening due to vibrations or thermal expansion, which can occur during engine operation.

Exhaust Outlet Security

The exhaust outlet is a critical point where gases exit the engine. The Retaining Clamp ensures that the connection at the exhaust outlet remains secure. This is important for maintaining the efficiency of the exhaust system and preventing any potential leaks that could lead to performance issues or safety hazards.

Exhaust Connection Integrity

Exhaust connections, including those between the exhaust manifold and the catalytic converter, require robust clamping to withstand high temperatures and pressures. The Retaining Clamp contributes to the integrity of these connections by providing a reliable seal. This helps in maintaining the flow of exhaust gases and ensuring that the system operates within designed parameters.

Conclusion

In summary, the Part 3352492 Retaining Clamp is integral to the secure and efficient operation of engine systems. Its role in stabilizing connections, securing the exhaust outlet, and maintaining exhaust connection integrity underscores its importance in engine performance and reliability.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.