This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3897712 Retaining Clamp is a specialized component designed for use in commercial trucks. It plays a role in securing various parts within the truck’s systems, ensuring they remain in place under operational conditions. This clamp contributes to the overall reliability and performance of the truck by maintaining the integrity of connections and assemblies.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold components in place. They operate by applying pressure to secure parts together, preventing movement or separation. These clamps are integral in various mechanical systems, providing stability and ensuring that parts function as intended under different operational stresses 1.

Purpose of the 3897712 Retaining Clamp

This Cummins part is specifically designed to secure components within a truck’s systems. It maintains the structural integrity of connections, particularly in areas where vibrations or dynamic loads are present. This clamp is applied in various truck systems to ensure that parts remain securely fastened, contributing to the safe and efficient operation of the vehicle.

Key Features

The 3897712 Retaining Clamp is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operation. Its design includes features that enhance its functionality, such as a robust clamping mechanism that provides a secure hold. Additionally, the clamp is engineered to be easy to install and remove, facilitating maintenance and repair processes.

Benefits

The use of the 3897712 Retaining Clamp offers several advantages. It contributes to improved system reliability by ensuring that components remain securely in place. The clamp’s design allows for ease of installation, reducing downtime during maintenance. Furthermore, its construction facilitates straightforward maintenance, enabling quick inspections and replacements when necessary.

Installation Process

Installing the 3897712 Retaining Clamp involves several steps to ensure proper securing of components. First, the area where the clamp will be installed should be cleaned and inspected for any debris. The clamp is then positioned over the components it is designed to secure. Using the appropriate tools, the clamp is tightened to the manufacturer’s specified torque, ensuring a secure fit without over-tightening, which could damage the components or the clamp itself.

Troubleshooting Common Issues

Common issues with retaining clamps may include loosening over time due to vibrations or improper installation. To address these problems, regular inspections are recommended to ensure the clamp remains securely fastened. If loosening is detected, the clamp should be re-tightened to the specified torque. In cases where the clamp shows signs of wear or damage, replacement is advised to maintain system integrity.

Maintenance Tips

Regular maintenance of the 3897712 Retaining Clamp is key to ensuring its longevity and optimal performance. This includes periodic inspections to check for signs of wear, corrosion, or loosening. Cleaning the clamp and its surrounding area can prevent the accumulation of dirt and debris, which could affect its functionality. Following the manufacturer’s guidelines for inspection intervals and maintenance procedures will help in preserving the clamp’s effectiveness.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, filtration systems, and other components designed to enhance the performance and reliability of commercial vehicles 2.

Compatibility with Cummins Engines

The Retaining Clamp part number 3897712, manufactured by Cummins, is designed to fit seamlessly within a variety of Cummins engine models. This part is essential for securing and stabilizing components within the engine, ensuring optimal performance and longevity.

Compatibility with 6C8.3 Engines

In the 6C8.3 engine series, the retaining clamp part 3897712 is utilized to secure various engine components, maintaining their position and integrity under operational conditions. This ensures that the engine operates smoothly and efficiently, reducing the risk of mechanical failure.

Compatibility with QSM11 CM570 Engines

Similarly, in the QSM11 CM570 engine series, the retaining clamp part 3897712 plays a crucial role in maintaining the structural integrity of the engine. By securing key components, this part helps in preventing misalignment and wear, which can lead to costly repairs and downtime.

Grouping of Engine Models

Both the 6C8.3 and QSM11 CM570 engines benefit from the use of the retaining clamp part 3897712. This part is designed to fit these engines precisely, ensuring that it performs its function effectively across different engine models within the same series. The compatibility of this part across these engines highlights its versatility and importance in maintaining engine stability and performance.

Role of Part 3897712 Retaining Clamp in Engine Systems

The 3897712 retaining clamp is an essential component in the assembly and maintenance of various engine systems. It ensures secure fastening and alignment of components, contributing to the overall efficiency and reliability of the engine.

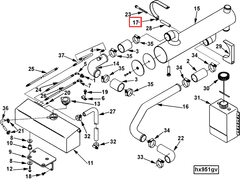

Heat Exchanger Systems

In heat exchanger systems, the 3897712 retaining clamp is utilized to hold tubes, fins, and other critical elements in place. This securement is vital for maintaining the structural integrity of the heat exchanger, allowing for optimal heat transfer between fluids. The clamp ensures that components remain aligned, preventing leaks and enhancing the system’s performance.

Engine Packages

Within engine packages, the 3897712 retaining clamp plays a significant role in securing various sub-assemblies. It is often used to fasten sensors, wiring harnesses, and other accessories to the engine block or frame. This secure attachment ensures that these components remain in their designated positions, reducing the risk of damage or malfunction during operation.

Product Installation

During the installation of engine products, the 3897712 retaining clamp is employed to hold newly installed parts in place. Whether it’s securing a new fuel injector, an air intake component, or an exhaust system part, the clamp ensures that these elements are correctly positioned and tightly fastened. This is particularly important in ensuring that the installation process is smooth and that the components function as intended once the engine is operational.

Overall Engine Systems

Across various engine systems, the 3897712 retaining clamp contributes to the stability and reliability of the assembly. By securely fastening components, it helps maintain the precise alignment necessary for the engine to operate efficiently. This is especially important in high-performance engines where even minor misalignments can lead to significant issues.

Conclusion

The 3897712 retaining clamp is a versatile and indispensable component in engine systems, ensuring that various parts are held firmly in place, thereby contributing to the engine’s overall performance and longevity. Regular maintenance and proper installation are key to maximizing the effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.