This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

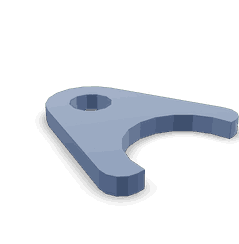

The Cummins 3924933 Retaining Clamp is a component designed for use in heavy-duty truck maintenance and operation. Its purpose is to secure various components within the truck’s system, ensuring they remain in place and function correctly under operational conditions. The significance of this clamp lies in its ability to contribute to the overall reliability and performance of the truck, making it a valuable part in the maintenance regimen of heavy-duty vehicles.

Function and Operation

The Cummins 3924933 operates by securing components within the truck’s system, preventing them from shifting or becoming dislodged during operation. This function is vital for maintaining the integrity of the truck’s systems, as unsecured components can lead to inefficiencies, increased wear, or even failure of the system they are part of. By ensuring components remain in their designated positions, the Retaining Clamp plays a role in the consistent and reliable operation of the truck.

Key Features

The Cummins 3924933 is characterized by several key features that enhance its performance. It is constructed from durable materials, ensuring it can withstand the rigors of heavy-duty truck operation. The design of the clamp includes elements that allow for easy installation and removal, while still providing a secure hold on the components it is meant to retain. Additionally, the clamp may feature unique attributes such as corrosion resistance or the ability to accommodate a range of component sizes, further enhancing its utility and effectiveness.

Benefits of Using the Retaining Clamp

Utilizing the Cummins 3924933 offers several advantages. It improves the security of components within the truck’s system, reducing the risk of operational issues arising from component displacement. The clamp’s durable construction contributes to enhanced system durability, potentially leading to longer intervals between maintenance checks. Furthermore, by ensuring components remain securely in place, the Retaining Clamp may contribute to cost savings through reduced maintenance needs and extended component lifespan.

Installation Process

Installing the Cummins 3924933 requires following a specific procedure to ensure it functions correctly. The process involves identifying the correct location for the clamp, positioning it around the component to be secured, and then tightening it to the manufacturer’s specified torque. It is important to consider the orientation of the clamp and ensure it does not interfere with other components or systems. Best practices include verifying the clamp’s security after installation and periodically checking its condition during routine maintenance.

Maintenance and Troubleshooting

Maintaining the Cummins 3924933 involves regular inspection for signs of wear, corrosion, or damage. Common issues may include loosening of the clamp or degradation of its material, which can be addressed by re-tightening or replacing the clamp as necessary. Troubleshooting procedures should include checking for proper installation and ensuring the clamp is compatible with the components it secures. Regular maintenance of the clamp contributes to its longevity and continued effective operation.

Safety Considerations

When working with the Cummins 3924933, it is important to observe several safety guidelines. These include ensuring the truck is turned off and the engine is cool before beginning any work. Proper handling of the clamp is necessary to avoid injury, and tools should be used correctly to install and remove the clamp. Additionally, it is crucial to follow all manufacturer recommendations for torque specifications and maintenance intervals to ensure the clamp operates safely and effectively.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and durability of vehicles and equipment. Cummins’ commitment to excellence is reflected in its extensive portfolio of products and services, catering to a wide range of applications and customer needs.

Cummins Retaining Clamp Part 3924933 Compatibility

The Cummins Retaining Clamp part number 3924933 is designed to fit a variety of Cummins engines, ensuring secure and reliable performance. This part is integral to maintaining the integrity of engine components by providing necessary retention and stability.

Compatible Engines

- 6B5.9

- 6C8.3

- ISB5.9 CM2880 B149

Grouping by Engine Series

-

6B5.9 and 6C8.3: These engines are part of the Cummins B-Series, known for their robust design and efficiency. The retaining clamp part 3924933 is specifically engineered to fit these models, ensuring that critical components remain securely fastened under various operating conditions.

-

ISB5.9 CM2880 B149: This engine belongs to the Cummins ISB Series, which is widely recognized for its power and reliability in heavy-duty applications. The retaining clamp part 3924933 is compatible with this model, providing the necessary support to maintain engine performance and longevity.

Understanding the Role of Part 3924933 Retaining Clamp in Engine Systems

The part 3924933 retaining clamp is an essential component in the secure arrangement of various engine systems. Its primary function is to ensure that components remain firmly in place, thereby maintaining the integrity and efficiency of the engine’s operation.

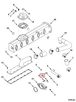

Turbocharger Integration

In turbocharger systems, the retaining clamp plays a significant role in securing the turbocharger to its designated location. This ensures that the turbocharger operates within the optimal parameters, enhancing the engine’s performance and reliability. The clamp helps in minimizing vibrations and potential misalignments that could arise during operation.

Exhaust System Stability

The retaining clamp is instrumental in the secure attachment of the exhaust manifold to the engine. This connection is vital for the efficient flow of exhaust gases away from the combustion chamber. By ensuring a tight and stable fit, the clamp prevents leaks and reduces the risk of exhaust-related issues, such as backpressure, which can adversely affect engine performance.

Water Inlet and Plumbing Connections

For systems involving an exhaust cooler water inlet tube and aftercooler water plumbing, the retaining clamp ensures that these tubes are securely fastened. This is particularly important in maintaining the correct flow of cooling water, which is essential for regulating the temperature of the exhaust gases and enhancing the overall efficiency of the engine.

Exhaust Recirculation System

In exhaust recirculation systems, the retaining clamp is used to secure the recirculation water plumbing. This ensures that the recirculated exhaust gases are effectively managed, contributing to reduced emissions and improved engine performance. The clamp’s role in this system is to maintain the structural integrity of the plumbing, preventing any potential leaks or disconnections.

Manifold and Plumbing Security

The retaining clamp is also utilized in securing various manifolds and plumbing components throughout the engine system. Whether it’s the intake manifold or exhaust plumbing, the clamp ensures that these parts remain in their correct positions, facilitating smooth operation and preventing any potential damage or performance issues.

Conclusion

The Cummins 3924933 retaining clamp is a fundamental component in the secure and efficient operation of various engine systems. Its application across different components underscores its importance in maintaining the overall performance and reliability of the engine. Regular maintenance and adherence to safety guidelines are essential for ensuring the longevity and effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.